Concrete Floor Radiant Heating Systems

Related Images about Concrete Floor Radiant Heating Systems

Electric Radiant Floor Heating: Basics, Cost, Pros & Cons

/5216244513_abe93aacd8_o-56a49ef05f9b58b7d0d7e052.jpg)

Some individuals cover their concrete floor with floor coverings but one cannot argue with unpolluted capacity as well as the durability of concrete. Water based paints are generally not a great idea with regards to concrete floors, as they normally don’t adhere to the surface area very nicely.

Radiant Heating Installations, Cost Information and Trade Assistance by Contractors Solutions

In case you are contemplating a polished concrete floors then the very first option of yours is going to be if you stain the flooring. In addition, floors made up of concrete are actually long-lasting, costs cheaper thanks to lower fee of labor and easy to clean as opposed to other flooring types. Treated concrete floors are several of the earth’s most durable.

in floor heating Radiant Heating RPM DO IT YOURSELF – YouTube

Another simple and elegant way of utilizing polished concrete which will also reduce costs on your new house project is to make the foundation a complete slab which even functions as the floor. Lastly, polished concrete may be utilized not only for the flooring of yours. Concrete cleaning solutions are specifically created to eliminate ground in dirt and leave behind a pleasant glow on polished concrete floor.

Radiant Floor Heating Systems

Installing a Radiant Floor Heat System DoItYourself.com

Radiant Floor Heat Frequently Asked Questions – The Concrete Network

Concrete Contractors Warm up to Radiant Heating Systems Concrete Decor

Ontario In-Floor Heating Radiant Floor Heating Toronto

Radiant Heating

Radiant Floor Heat Frequently Asked Questions – The Concrete Network

Concrete Flatwork – ‘in-the-floor’ Radiant Heating

Radiant Floor Heating – Radiant Works

Tips for Designing and Installing Radiant Floor Heat – The Concrete Network

School Addition Goes Green with Radiant Heat – Home Construction Improvement

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Concrete Floor Radiant Heating Systems: A Comprehensive Guide

Introduction

In recent years, radiant heating systems have gained significant popularity among homeowners and commercial property owners alike. One type of radiant heating system that has garnered particular attention is the concrete floor radiant heating system. This innovative heating solution offers numerous benefits, including energy efficiency, improved comfort, and even heat distribution. In this comprehensive guide, we will delve into the intricacies of concrete floor radiant heating systems, exploring their components, installation process, maintenance requirements, and potential drawbacks.

I. Understanding Concrete Floor Radiant Heating Systems

A. What is a Concrete Floor Radiant Heating System?

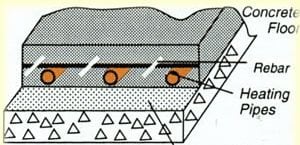

A concrete floor radiant heating system is a method of providing heat to a space by utilizing warm water that circulates through pipes embedded within the concrete flooring. This type of system relies on the principle of radiant heat transfer, where warmth radiates from the heated floor surface to warm the surrounding space evenly and efficiently.

B. How Does a Concrete Floor Radiant Heating System Work?

The system consists of three key components: a heat source (such as a boiler or water heater), a network of pipes embedded in the concrete flooring, and control mechanisms (thermostats) to regulate temperature. The heat source warms the water, which is then circulated through the pipes via a pump or manifold system. As the warm water flows through the pipes in the concrete flooring, it transfers its heat energy to the surrounding concrete and ultimately radiates it into the room.

C. What Are the Advantages of Concrete Floor Radiant Heating Systems?

1. Energy Efficiency: Concrete floor radiant heating systems are highly energy-efficient compared to traditional forced-air heating systems. The even distribution of heat ensures minimal heat loss, while lower operating temperatures contribute to reduced energy consumption.

2. Improved Comfort: Unlike forced-air systems that generate uneven heat distribution and drafts, radiant floor heating systems create a comfortable environment with consistent warmth throughout the space.

3. Design Flexibility: With radiant heating systems, the absence of bulky radiators or ductwork allows for greater design freedom and flexibility in room layout and furniture placement.

4. Health Benefits: Radiant floor heating eliminates the circulation of dust, allergens, and airborne particles often associated with forced-air systems, leading to improved indoor air quality and respiratory health.

II. Installation Process

A. Pre-installation Considerations

Before installing a concrete floor radiant heating system, several key factors need to be considered:

1. Flooring Type: While concrete is the most common flooring material for radiant heating systems, other options like tile, stone, or engineered wood can also be used. However, it’s crucial to ensure that the flooring material has suitable thermal conductivity to maximize heat transfer efficiency.

2. Insulation: Adequate insulation beneath the concrete slab is essential to prevent heat loss downward into the ground. Proper insulation ensures that the majority of heat is directed upward into the living space.

3. Heat Source Selection: Depending on the size of the area and heating requirements, different heat sources such as boilers or water heaters may be chosen. It’s important to consult with a professional to determine the appropriate heat source for your specific needs.

B. Installation Steps

1. Floor Preparation: The existing flooring (if any) is removed to expose the subfloor or concrete slab. The surface is thoroughly cleaned and leveled before insulation is installed.

2. Insulation Installation: A layer of rigid foam insulation is placed over the subfloor or concrete slab to minimize downward heat loss and optimize upward Heat transfer. The insulation is cut and fitted to cover the entire floor area, with special attention given to sealing any gaps or joints.

3. Piping Installation: The PEX (cross-linked polyethylene) pipes are laid out in a serpentine pattern across the floor area, ensuring even spacing between the pipes. The pipes are secured using clips or fasteners to prevent movement during concrete pouring.

4. Pressure Testing: Before pouring the concrete, the system is pressurized to check for any leaks or weak points in the piping. This step ensures that the system functions properly and prevents future issues.

5. Concrete Pouring: Once the pressure test is successful, a layer of concrete is poured over the entire floor area, covering the pipes and insulation. The concrete is leveled and smoothed using tools like trowels or floats.

6. Finishing Touches: After the concrete has cured, typically for several weeks, the flooring material of choice (such as tile or wood) can be installed on top of it. The final step involves connecting the radiant heating system to the heat source and controls.

III. Maintenance and Care

To ensure optimal performance and longevity of a concrete floor radiant heating system, regular maintenance and care are necessary:

1. Cleaning: Regularly clean the flooring material according to its specific requirements to prevent dirt or debris from affecting heat transfer.

2. Insulation Check: Periodically inspect the insulation beneath the concrete slab to ensure it remains intact and properly sealed, minimizing heat loss.

3. System Inspection: Have a professional inspect the system periodically to check for any leaks, blockages, or malfunctions. They can also perform maintenance tasks like flushing the system or replacing worn-out components.

4. Thermostat Adjustment: Adjust the thermostat settings according to your comfort needs and seasonal changes. This helps optimize energy usage and prevents unnecessary heating.

5. System Protection: Take precautions to protect the system during construction or renovation activities that could potentially damage the pipes or insulation.