Concrete Floor Finish Standards

Related Images about Concrete Floor Finish Standards

Hardwood Finish Floor ProSource Wholesale

Sealants, like a polymer flooring seal, provide many positives to interior and exterior flooring surfaces and tend to be an excellent addition to a concrete floor maintenance system. Caring for the decorative concrete floors of yours is not much different compared to the normal upkeep you do in any aspect of the home of yours.

Floor Finishes: Concrete Floor Finishes Toronto

With regards to floors, polished concrete floors are materials which are excellent, which are more ordinarily used. The point is: concrete comes pre installed in most homes, because most houses are built on concrete slabs. The period it takes to finish the setting up of a concrete floor is based on how big and tiny the floor area is actually.

Floor Finish Leading by Concrete Innovations – Concrete Innovations

Polished concrete floors are an exceptional method of flooring that are more and more becoming a way of life for most home and business people. Polished concrete flooring surfaces also have quite a few advantages making them a green, affordable and practical method for apartments and housing. In room and shop options, concrete floor is less loud than floorboards of tiles.

How to Place and Finish a Concrete Floor (with Pictures) – wikiHow

Floor Finishing Concrete Construction Magazine Concrete Flatwork, Detail, Concrete

Precast Concrete Finishes Architectural Precast Concrete

Finished Floor Surface – Concrete Innovations

Construction Updates: VARIOUS TYPES OF FLOOR FINISHES IN

External Concrete FLooring – Level Best Concrete Flooring

JEC – Our Business: What We Do

Flatness and Levelness of Industrial Concrete Floors – The Concrete Network

F-rated Floors Repaired to Achieve A+ Status Concrete Decor

Details – Floors Details DWG Detail for AutoCAD • Designs CAD

Superior Prestressed Precast Concrete Balconies

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Concrete Floor Finish Standards: Ensuring Quality and Durability

Introduction:

Concrete floors are a popular choice for both residential and commercial spaces due to their durability, versatility, and low maintenance requirements. However, achieving the desired aesthetics and functionality of a concrete floor depends greatly on the finish applied. In order to ensure quality and consistency, industry professionals have established concrete floor finish standards that provide guidelines for the selection, application, and maintenance of various floor finishes. This article will delve into the different types of concrete floor finishes, explain the standards associated with each type, and address frequently asked questions related to concrete floor finish standards.

I. Types of Concrete Floor Finishes:

a) Polished Concrete:

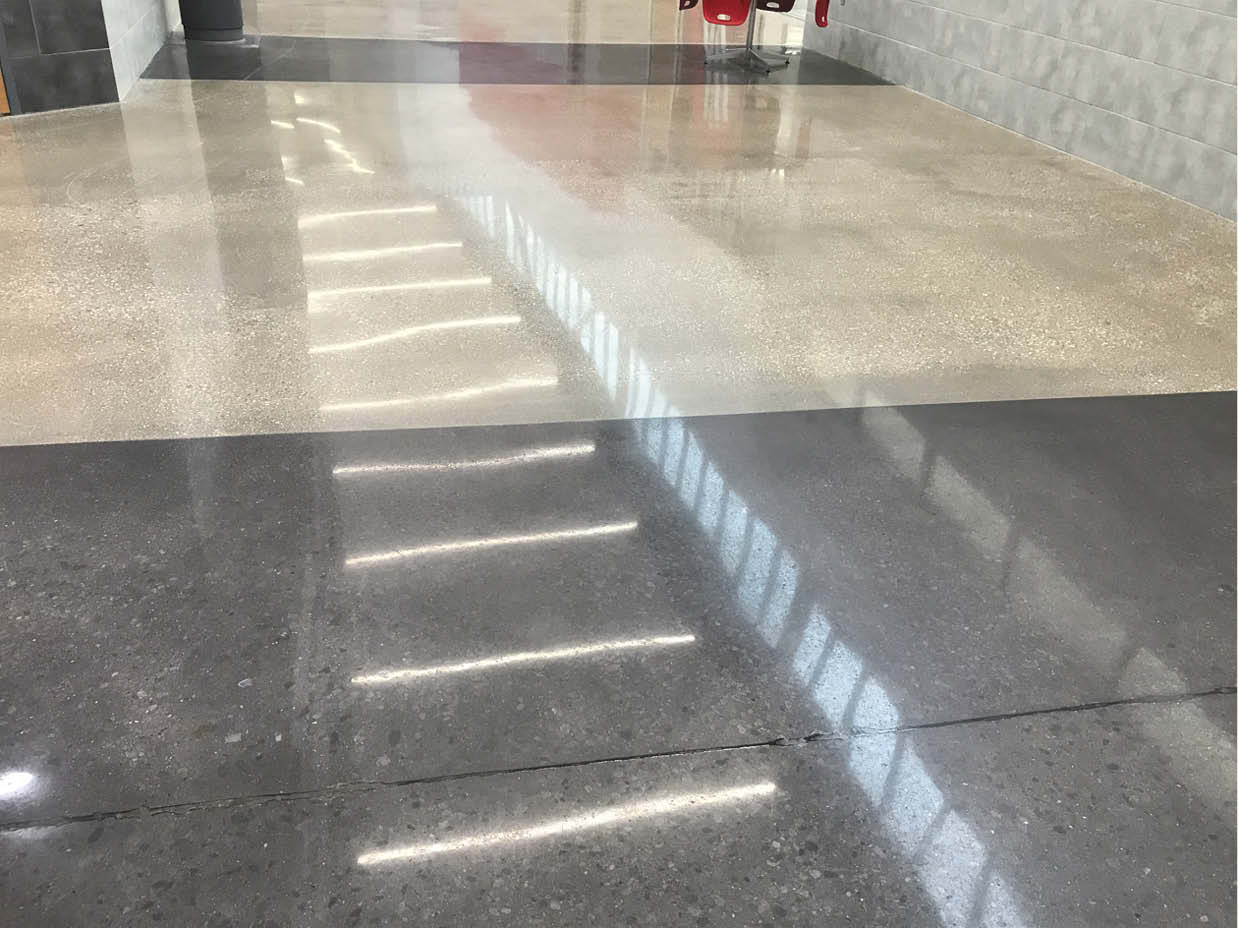

Polished concrete is a highly sought-after finish that offers a sleek, glossy appearance while maintaining the natural beauty of the concrete. It involves a multi-step process of grinding, honing, and polishing the surface using progressively finer diamond abrasives. The level of sheen achieved can range from low to high gloss, depending on the desired aesthetic.

FAQs:

Q1: What are the benefits of polished concrete?

A1: Polished concrete provides numerous benefits including enhanced durability, improved light reflectivity, ease of maintenance, resistance to stains and chemicals, and reduction in dusting.

Q2: Are there different levels of polish?

A2: Yes, there are four levels of polish – cream polish (low gloss), salt-and-pepper polish (medium gloss), semi-polish (high gloss), and high-polish (mirror-like finish).

b) Stained Concrete:

Stained concrete is another popular option that adds color and depth to plain concrete floors. This finish involves applying acid-based or water-based stains that penetrate the surface and react chemically with the minerals in the concrete. The result is a variegated or mottled appearance that mimics natural stone or marble.

FAQs:

Q1: Can stained concrete be used outdoors?

A1: Yes, stained concrete can be used both indoors and outdoors. However, it is important to use a UV-resistant sealer for outdoor applications to prevent fading or discoloration.

Q2: Are there limitations in terms of color options?

A2: No, stained concrete offers a wide range of color options including earth tones, vibrant hues, and even custom colors. The final color may vary depending on the concrete’s composition, age, and surface conditions.

c) Epoxy Coating:

Epoxy coating is a popular choice for industrial and commercial settings due to its exceptional durability and chemical resistance. It involves applying multiple layers of epoxy resin to the concrete surface, creating a seamless, high-gloss finish that is highly resistant to wear, impacts, and stains.

FAQs:

Q1: Can epoxy coatings be applied to existing concrete floors?

A1: Yes, epoxy coatings can be applied to existing concrete floors as long as the surface is properly prepared by cleaning, degreasing, and repairing any cracks or imperfections.

Q2: How long does an epoxy coating last?

A2: When properly installed and maintained, an epoxy coating can last up to 10-20 years or even longer. Regular maintenance such as routine cleaning and occasional recoating can extend its lifespan.

II. Concrete Floor Finish Standards:

a) ASTM International Standards:

ASTM International, formerly known as the American Society for Testing and Materials, has established a set of standards for various aspects of concrete floor finishes. These standards cover areas such as surface Preparation, moisture testing, application methods, and finishing techniques. By following these standards, contractors can ensure that concrete floors meet specific quality and performance requirements.

b) Gloss Levels:

Concrete floor finishes are often categorized into different gloss levels to meet specific aesthetic preferences and functional needs. These gloss levels range from low gloss (matte) to high gloss (mirror-like finish). The choice of gloss level depends on factors such as the desired appearance, maintenance requirements, and lighting conditions in the space.

c) Slip Resistance:

Slip resistance is an important consideration for concrete floor finishes, especially in areas with high foot traffic or where safety is a concern. Various methods can be used to measure slip resistance, such as the pendulum test or the coefficient of friction test. The appropriate level of slip resistance should be determined based on the specific application and regulatory requirements.

d) Maintenance and Cleaning:

Proper maintenance and cleaning are essential for preserving the appearance and longevity of concrete floor finishes. Depending on the type of finish, recommended maintenance practices may include regular sweeping or vacuuming, damp mopping, periodic buffing or polishing, and the use of appropriate cleaning products. It is important to follow manufacturer guidelines for maintenance to avoid damaging the finish.

e) Environmental Considerations:

Concrete floor finishes can have environmental implications in terms of their production process, VOC emissions, and potential for recycling or reuse. Choosing finishes that are low in VOCs (volatile organic compounds), using sustainable materials or recycled content, and implementing proper waste management practices can help reduce the environmental impact of concrete floor finishes.