Concrete Floor Construction Techniques

Related Images about Concrete Floor Construction Techniques

Reinforced Concrete,floor Construction Stock Photo – Image: 37372952

A spot remover specifically developed for concrete floor, similar to those sold at expert janitorial supply companies, can assist you. On the other hand, a polished concrete floor, which is highly reluctant to stains and scuffs, could be simply mopped when necessary. The finished effect is definitely a uniform surface, joints are slightly noticeable.

Subgrades and Subbases for Slabs Concrete Construction Magazine

The style of the tile may be used as the same color to spot the concrete floor. Concrete floors are durable and hard. The concrete floors is there to remain and whenever you move on at some point, the new owners will have the ability to enjoy the benefits this sort of flooring offers. Most common flooring have arduous cleaning requirements.

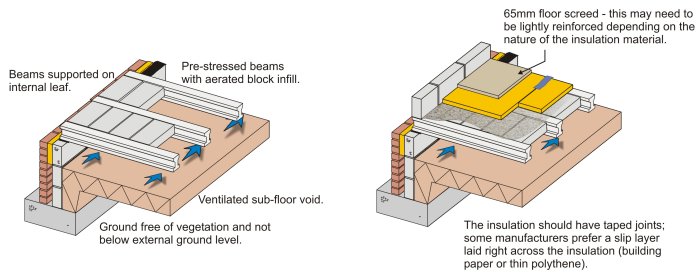

6. Ground Floors – Construction Studies

Nonetheless, it's critical for every home owner who's making use of the polished concrete floors to determine how the polished floor is actually achieved when all is said and done. Acid Stain concrete floorings have some time and once again confirmed their reliability with regards to cost efficiency, durability and the strength of the flooring.

How thick is the concrete on the floors of a multi story building? – Quora

UNIQUE CONCRETE SYSTEM – Concrete floor preparation – YouTube

suspended concrete ground floor construction Viewfloor.co

Concrete Ring Wall Evaluation BP Pipeline – Muscatine, IA – CTLGroup

Industrial Concrete Flooring Finishes – Polishing & Coatings – The Concrete Network

Why is Concrete an Excellent Choice for Flooring?

Reinforced concrete structure of building — Stock Photo © frogtravel #15345561

M.Construction Services Concrete Floors

Pouyan Madanipour SRT251: May 2008

Broom Finish Perfect Finish Concrete

Perfecting Firestopping: Materials, techniques, and specifications to reduce building fire

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

– Include relevant facts, figures and statistics

Concrete Floor Construction Techniques

Concrete floors have become increasingly popular in both residential and commercial buildings in recent years. This is due to their strength, durability, and affordability compared to other flooring materials. In order for concrete floors to remain strong and look great for many years to come, proper construction techniques must be used. This article will discuss the various concrete floor construction techniques to help ensure a successful installation.

Preparing the Subfloor

The first step in constructing concrete floors is to prepare the subfloor. The subfloor is the surface that the concrete will be poured onto, so it needs to be level and free of any debris or damage. If there is existing flooring, it should be removed and the area should be cleaned. Any loose materials should also be removed if possible. Once the subfloor has been prepared properly, it should be covered with a vapor barrier before installing any reinforcement materials.

Installing Reinforcement Materials

Once the subfloor has been prepared, reinforcement materials should be installed. These can include wire mesh or rebar, depending on the type of concrete being used and the desired strength of the floor. The reinforcement materials should be laid out in an appropriate pattern and securely attached to the subfloor. Additionally, expansion joints should be cut into the subfloor before pouring the concrete to help prevent cracking due to temperature changes or movements in the underlying structure.

Pouring and Finishing Concrete

After all of the preparation work has been completed, it’s time to pour and finish the concrete. The concrete should be mixed according to manufacturer’s specifications before being poured into place. The concrete should then be spread evenly using a trowel or other appropriate tool before being smoothed out with a float or broom for texture. After this step is complete, any decorative touches such as staining or stamping can be added if desired. Finally, a sealant should be applied to help protect the surface from damage due to wear and tear or moisture.

FAQs Regarding Concrete Floor Construction Techniques

Q: What kind of reinforcement materials are typically used when constructing a concrete floor?

A: Typically wire mesh or rebar are used when constructing a concrete floor depending on the desired strength of the floor and type of concrete being used. It is important that these materials are securely attached to the subfloor before pouring and finishing the concrete in order for them to provide adequate support.

Q: How can I ensure that my concrete floor remains level after installation?

A: Leveling is an important part of ensuring that your concrete floor remains even after installation. The subfloor must first be properly leveled before any reinforcement materials are installed in order for them to provide adequate support for the finished product. Additionally, expansion joints should also be cut into the subfloor before pouring in order to allow space for movement due to temperature changes or shifting structures underneath without causing cracks in your finished product.

Q: What steps are necessary after pouring and finishing my concrete floor?

A: After pouring and finishing your concrete floor you will need to apply a sealant in order to protect it from damage due to wear and tear or moisture over time. Additionally, If you desire any decorative touches such as staining or stamping, these should be added after the sealant has been applied.

What tools are needed for concrete floor construction?

1. Trowels2. Concrete Mixer

3. Bull Float

4. Power Screed

5. Jointer or Edger

6. Grinder or Polisher

7. Protective Gear (gloves, dust mask, etc.)

8. Tape Measure

9. Level

10. Chalk Line

11. Hammer and Nails

12. Wire Mesh or Rebar (for reinforcement)

13. Expansion Joints (to allow for movement)

14. Sealant (to protect against wear and tear or moisture)

What are the steps involved in constructing a concrete floor?

1. Prepare the Sub-Base: Before pouring a concrete floor, excavation and grading of the sub-base must be done. This step will ensure that the floor is level and stable.2. Lay Out Rebar: Rebar is an important element that provides structural strength to concrete floors. It should be laid out in a grid pattern and securely tied together with wire or rebar ties.

3. Install Wire Mesh: After laying out the rebar, wire mesh should be installed on top. This serves as extra reinforcement and helps prevent cracking in the concrete floor.

4. Pour Concrete: Once all of the preparation work is complete, concrete can be poured into the area. It should be placed in layers to ensure even distribution and a smooth finish.

5. Level and Finish Concrete Floor: After the concrete has been poured, it needs to be leveled with a trowel or screed board to achieve a smooth surface. If desired, a stamping or texturing tool can also be used to create patterns in the concrete floor.

6. Cure Concrete Floor: Once the concrete has been finished, it needs to be allowed to cure for several days before it can be used. This curing period allows the concrete to harden and reach its full strength.