Wood Floor Texture Map

Related Images about Wood Floor Texture Map

Plank Map

If you're still unsure then any experienced wood flooring contractor should be able to provide you assistance. This wood has character from plentiful natural traits. They are additionally a popular choice as they do not require sanding unlike other kinds of wood floors. This kind of hard wood floors is manufactured by bonding several tiers of wood under pressure that is high.

Wood Flooring Texture Map – wood flooring design

Wood floors which is engineered can completely modify the home's look and feel while not doing any other changes on to the residence's interior and for a reduced amount of price than traditional hardwood flooring. This particular kind of wood floors is affixed using staples, nails or glue. Instead, a layer of foam underlay is placed directly on top of the sub floor and the wood pieces are laid out in addition to this particular foam material.

Tiling Hardwood Floor Texture (1024×1024) – hardwood.jpg, Normal Map OpenGameArt.org

Although somewhat pricier than regular laminated engineered wood floor surfaces, reclaimed built wood floor surfaces has gotten reviews that are excellent from people with paid for and put in this "span of history" floors with complete fulfillment as well as in general strong recommendations. It's critical to hire an expert installation team that's familiar with wood and the reaction of its to moisture.

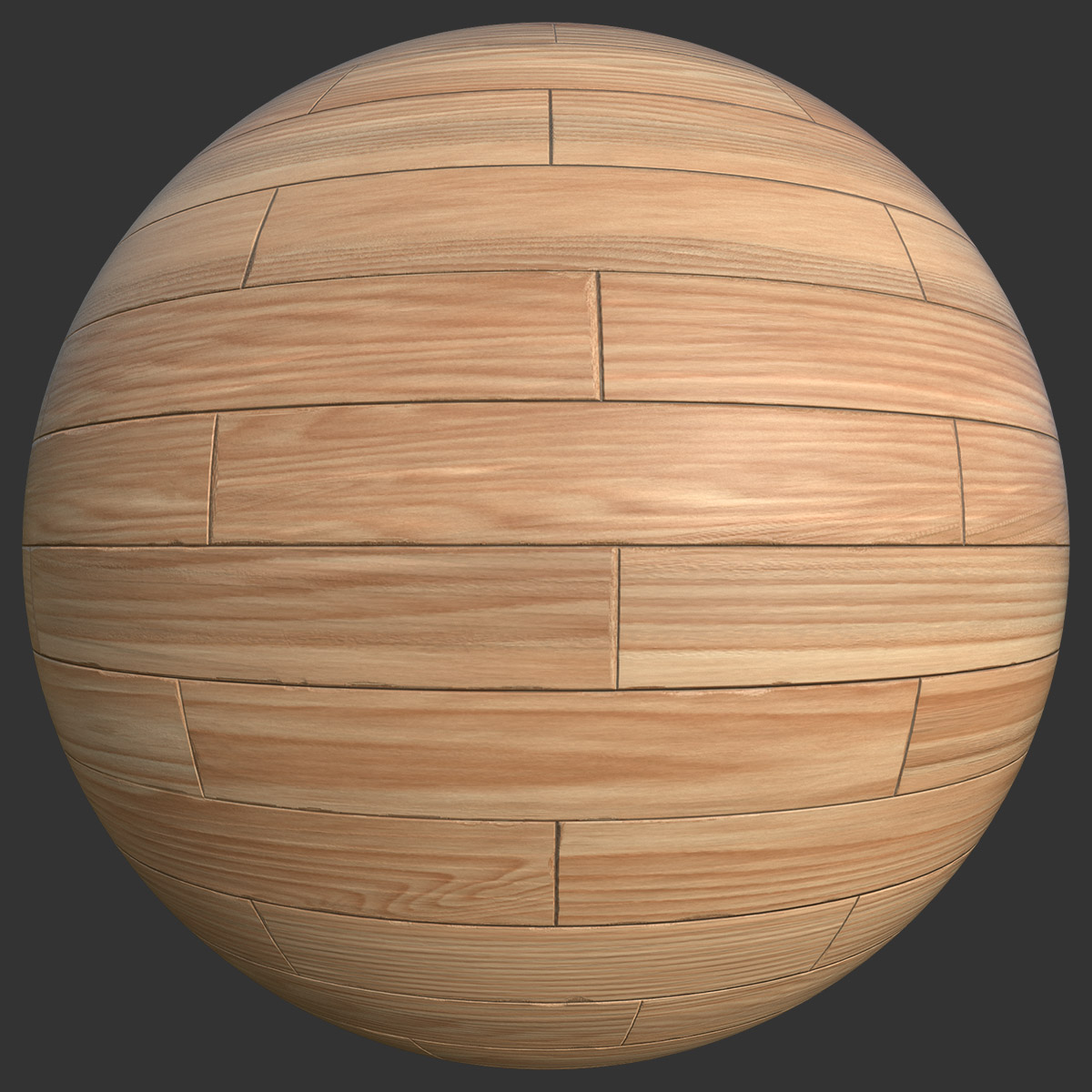

Cedar Wood Plank Texture Free PBR TextureCan

Wood Texture for Flooring and Pavement Free PBR TextureCan

Tileable Wood Planks + (Maps) Texturise Free Seamless Textures With Maps

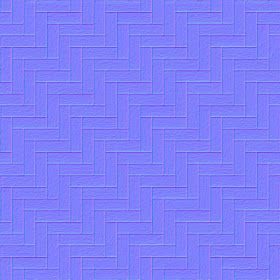

Texturise Free Seamless Textures With Maps: Oak Wood Parquet (Maps)

Wood Flooring Texture Map – wood flooring design

Burned Wood Texture – Seamless Texture with normalmap OpenGameArt.org

Wood & Stone Floor (Texture)

Seamless White Marble + (Maps) Texturise Free Seamless Textures With Maps

Wood Texture Wood Texture You can also download this photo… Flickr

Wooden Floor (Texture)

Free download 3d Texture of White Marble Tile floor BPR in HD high resolution 4k Free 3d

Related Posts:

- Wood Floor Modern Kitchen

- Wood Floor Garage Plans

- Real Wood Flooring In Kitchen

- Wood Floor Cork Underlayment

- Streak Free Wood Floor Cleaning

- Solid Wood Flooring White Washed Oak

- Engineered Wood Flooring Durability

- Wood Flooring Types Hardness

- Engineered Wood Flooring Formaldehyde Emission

- Wood Floors For Beach House

Introduction

Wood floor texture mapping is an important technique in the art of woodworking. It is a process of applying a wide range of textures and patterns to wood floors to create a unique look. This technique is used by professional woodworkers and home DIYers alike, as it allows them to customize the look and feel of the floors to suit their individual tastes. By using this technique, it is possible to create a one-of-a-kind floor that will be both visually appealing and highly durable. In this article, we will take a closer look at what wood floor texture mapping is, how it works, and what benefits it offers.

What Is Wood Floor Texture Mapping?

Wood floor texture mapping is a process of applying different textures and patterns to hardwood floors. The textures can range from light grainy patterns to more intricate designs such as swirls or even abstract shapes. The texture map is typically applied with a roller or brush, depending on the desired effect. It is possible to apply the texture map either directly to the wood or onto a vinyl backing material.

Once applied, the texture map provides a layer of protection against dirt and scratches while also providing a unique visual element. The texture map can be used to highlight certain features of the wood floor, such as knots or grain lines, or to create interesting patterns and designs. This technique is often used in combination with various stains and finishes, allowing for even greater customization of the finished product.

How Does Wood Floor Texture Mapping Work?

Wood floor texture mapping utilizes specialized equipment such as roller applicators and brushes that are designed specifically for this purpose. The equipment is used to apply the texture map evenly over the surface of the flooring material. The equipment can be adjusted to allow for varying levels of intensity when applying the texture map, resulting in different effects depending on how much pressure is applied during application.

In addition, the equipment can also be used to create unique patterns by overlapping certain sections of the texture map or by using different colors or shades of material in each section. This allows for a great deal of creativity when designing an individualized wood floor design that will truly stand out from other floors in your home or business.

Benefits Of Wood Floor Texture Mapping

One of the primary benefits of using wood floor texture mapping is that it provides an extra layer of protection against dirt and scratches while also creating unique visual elements that make your space stand out from others. Additionally, this technique can help reduce wear on your hardwood floors over time by providing an extra layer between your floors and everyday foot traffic.

In addition, using a texture map can help provide an extra level of insulation in colder climates as well as helping muffle sound in busy areas like kitchens or hallways where noise levels tend to be higher than other areas in your home or office building. Finally, it’s important to note that this technique can also add value to your home or business by increasing its aesthetic appeal and making it more attractive for potential buyers in case you ever decide to sell down the line.

FAQs About Wood Floor Texture Mapping

Q: What materials are used for wood floor texture mapping?

A: Wood floor texture maps are typically made from rubberized materials such As vinyl or polyurethane. These materials are designed to be durable and easy to work with, allowing for a quick and easy application process.

Q: How do I apply the texture map?

A: Texture maps can be applied using a roller or brush depending on the desired effect. If applying directly to wood, it is important to ensure that the wood is clean and dry before application in order to get the best results. If applying onto a vinyl backing material, it is recommended to use a heat gun or iron in order to create an even surface.