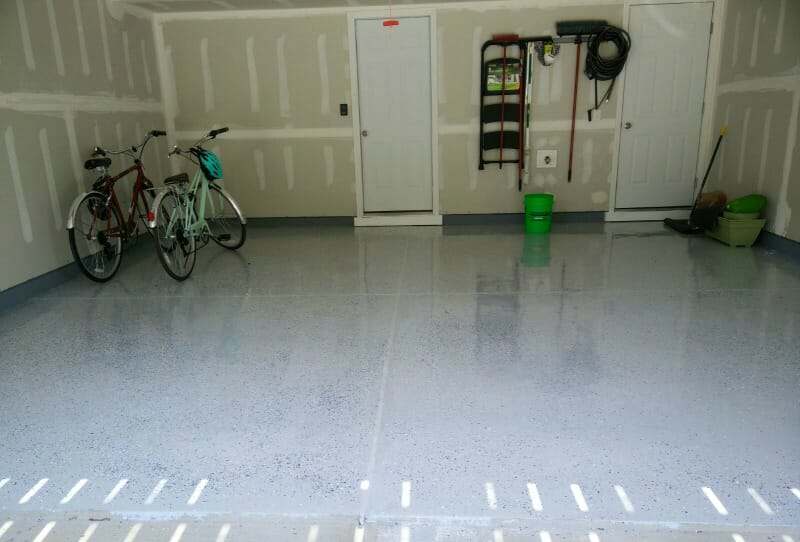

Urethane Concrete Floor Coating

Related Images about Urethane Concrete Floor Coating

Urethane Concrete Flooring Duraamen Engineered Products, Inc.

The polished concrete is fast becoming a standard problem in a lot of places around the world and this is mainly because many men and women are appreciative of its beauty and in addition because many instances only can not stand having some other kind of floor. Sealed concrete has an incredibly low environmental impact.

Epoxy Flooring, Urethane Systems, and Specialty Coatings RS Concrete

Nevertheless, the performance as well as visual appeal of concrete might be hampered by the useful safety aspects of its, especially for kids which are younger. When used in basements, possessing blank concrete floors is a more hygienic choice from moldy carpets & rugs.

Commercial & Industrial Urethane Cement Floor Coatings, Po… Flickr

Another simple and elegant way of utilizing polished concrete which will also reduce costs on your new house project is to make the foundation a complete slab that even operates as the floor. Lastly, polished concrete could be utilized not just for your flooring. Concrete cleaning solutions are specially formulated to get rid of ground-in dirt and leave behind a great shine on polished concrete floors.

What is a metallic epoxy floor coating? – West Pacific Coatings

Floor Coating and Repair Services – Paramount, California

Epoxy Flooring, Urethane Systems, and Specialty Coatings RS Concrete

Polyurethane vs. Epoxy Coatings – DCI Flooring Industrial Seamless Floors and Walls

Seamless Floor Coating Systems – VTI Contracting

![]()

Seamless Floor Coating Systems – VTI Contracting

![]()

Ballistic Concrete Coatings About Us Epoxy Concrete Coating Sacramento, CA

Epoxy Flake Flooring Luxury Concrete Coating

Reviewing RockSolid’s Polycuramine Garage Floor Coating All Garage Floors

Epoxy Coating Floor Coatings Westfield, MA

industrial-concrete-floor-trench-filling

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Urethane Concrete Floor Coating

Urethane concrete floor coating is an innovative and durable solution for protecting floors from wear and tear. It is a flexible and cost-effective way of protecting your floors from the elements, as well as providing a beautiful finish that looks like real stone or tile. Urethane concrete floor coating can be applied to many types of surfaces, including concrete, wood, brick, vinyl, metal, and more. It is also a great choice for industrial floors due to its high durability and resistance to abrasion and chemicals. With the right maintenance and care, urethane concrete floor coatings can last for many years, making it an ideal choice for any home or business.

Benefits of Urethane Concrete Floor Coating

Urethane concrete floor coating offers numerous benefits over traditional forms of flooring protection. One of the main advantages is its flexibility; it can be easily applied to a variety of surfaces without requiring any additional prep work. Additionally, it is extremely durable and resistant to scratches, abrasions, and chemicals. Furthermore, urethane concrete coatings can also reduce noise levels in a room by up to 30%, making it ideal for soundproofing purposes. Finally, it provides a beautiful finish that looks like real stone or tile without the need for costly installation.

Application Process

Applying urethane concrete floor coating is relatively straightforward. The first step is to prepare the surface by cleaning it thoroughly with a degreaser or soap and water solution. Once the surface is clean and dry, the urethane floor coating can be applied using either a roller or sprayer. The coating should be applied in thin layers until the desired thickness has been achieved. Finally, the urethane concrete floor coating should be allowed to cure overnight before use.

Maintenance & Care

To ensure that your urethane concrete floor coating lasts for many years to come, it is important to take proper care of it. Regular cleaning with soap and water will help keep it looking like new. Additionally, you should avoid walking on wet floors with street shoes as they may cause damage over time. If you do experience any scratches or damage on your urethane floor coating, you can easily repair it using a touch-up kit designed specifically for this purpose.

FAQs on Urethane Concrete Floor Coating

Q: What surfaces can I apply urethane concrete floor coating on?

A: Urethane concrete floor coating can be applied to many types of surfaces including wood, brick, concrete, vinyl, metal and more.

Q: Is urethane concrete floor coating durable?

A: Yes! Urethane concrete floor coating is extremely durable and resistant to abrasions and chemicals. It also provides excellent soundproofing properties which makes it ideal for industrial applications.

Q: How long does urethane concrete floor coating last?

A: With proper maintenance and care, urethane concrete coatings can last for many years before needing replacement or repairs.

What is the best urethane concrete floor coating?

The best urethane concrete floor coating is Sherwin-Williams Urethane Concrete Floor Coating. It is a two-part, high performance system that provides superior protection against wear, abrasion, and chemical spills. It is also highly resistant to oil, grease, and other chemicals and can resist temperatures up to 250°F (121°C). Additionally, it is easy to apply and provides a beautiful, gloss finish that looks like real stone or tile.What type of surface is required before applying a urethane concrete floor coating?

A urethane concrete floor coating should be applied to a clean, dry, and dust-free concrete surface. The surface should also be free of oils, solvents, sealers, and other contaminants. Additionally, any cracks or holes in the concrete should be filled with a suitable patching material before application.What types of preparation are necessary before applying a urethane concrete floor coating?

1. Make sure the concrete floor is clean and free of debris, dust, oils, and other contaminants.2. Repair any cracks or damage in the concrete floor prior to coating.

3. Use a chemical etching solution to prepare the concrete and open its pores for better adhesion.

4. Make sure the surface is dry before beginning the application process.

5. Use a primer or sealer to ensure optimal adhesion of the urethane floor coating.