Underlay For Wood Flooring Advice

Related Images about Underlay For Wood Flooring Advice

Underlayment For Laminate Flooring On Wood Subfloor Wood Flooring

Wood floors tend to be the healthy and balanced option, they require fewer chemical compounds to clean than many other floor coverings, & they don't catch dust and also fumes in the fibers or grow mold of the grout. Basically take existing flooring so you are directlyto floorboards/ concrete, then lay foam underlay by which timber goes onto. When old buildings, bridges, barns, industrial buildings, etcetera.

How to Choose the Perfect Hardwood Flooring UnderlaymentLearning Center

Avoid the hassle, mess as well as costly errors by working with your Austin wood floors professionally maintained by a respected nationwide company as Kiwi Services at exactly the same time that you have the carpets cleaned. You can not assume all floors are made equal, and only some possess the same intended use. Furthermore, wood floors improve the value of a residence and are therefore an asset.

Wood flooring over underlay Unique Bespoke Wood

The benefit of utilizing built wood flooring would be that it can be utilized straight over concrete (as you don't need to nail it during installation), or below quality (because moisture does not bother it as much as solid wood). The layers of plywood under the veneer are laid cross-ways, reducing the wood's capacity to increase and contract over the grains when there's a difference in moisture levels.

Fibreboard Underlay 5mm for Wood and Laminate Flooring – UK

Normandy Wharf Brushed&Oiled French Oak dual and single stave planks. Engineered flooring

The Top Reasons Why You Need An Underlayment For Hardwood Floors – Eco Cork Foam

How should I install an underlay? Beautiful laminate, timber & vinyl floors

Uncategorized Archives – TimberTown

Parquet Herringbone wood flooring with double border London

A002 Transition profile for vinyl flooring, 2700 mm Flooring Profiles and Accessories

Desert Oak Warm Natural MJ3551 Laminate Flooring Best at Flooring

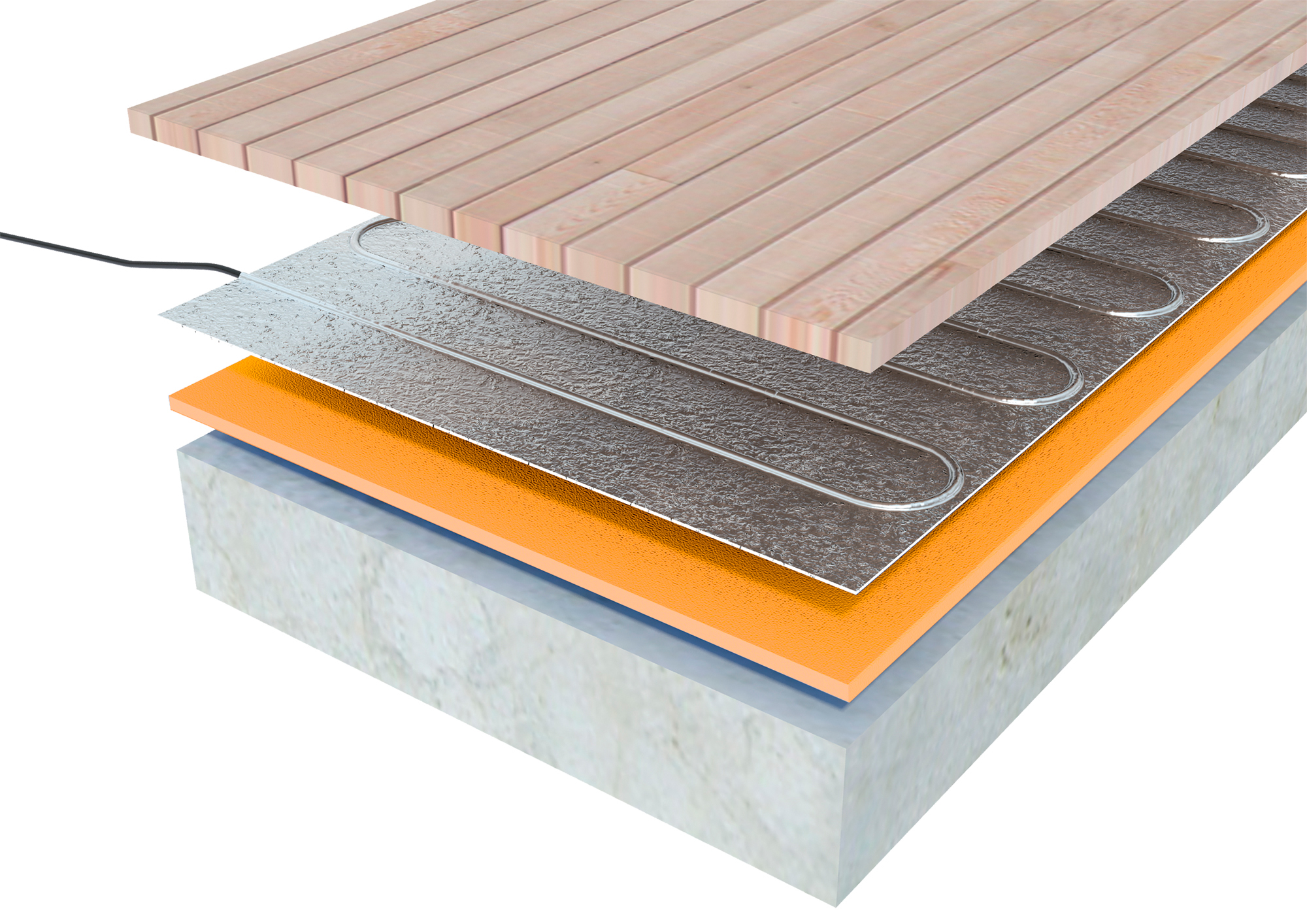

ProWarm Foil Heating Mats for Wood Flooring – Build It

Flooring Xtra LVT & Hybrid Stone Look Looselay Tiles Madison

Fitting Hexagon Wood Tiles floors – hexagon parquet floor

Related Posts:

- Wood Floor Modern Kitchen

- Wood Floor Garage Plans

- Real Wood Flooring In Kitchen

- Wood Floor Cork Underlayment

- Streak Free Wood Floor Cleaning

- Solid Wood Flooring White Washed Oak

- Engineered Wood Flooring Durability

- Wood Flooring Types Hardness

- Engineered Wood Flooring Formaldehyde Emission

- Wood Floors For Beach House

Underlay For Wood Flooring Advice

Installing a wood floor in your home can be a daunting task. Not only do you need to choose the right type of wood, but you also have to consider what kind of underlayment to use. Underlay is the layer between the subfloor and the wood flooring, and it serves several important functions. It helps protect the floor from moisture damage, improves sound insulation, and provides extra cushioning for increased comfort. To ensure your wood floors last for years to come, it’s important to choose the right type of underlayment.

What Is Underlay?

Underlay is a material that is placed between the subfloor and the finished floor. It serves several important functions, such as providing additional cushioning for increased comfort, reducing noise transmission from foot traffic, protecting against moisture damage, and helping to level out minor imperfections in the subfloor. The most common types of underlay are foam, felt, rubber, cork, and polyethylene film.

Types of Underlay for Wood Flooring

Foam Underlay: Foam underlay is made out of polyethylene foam and is one of the most popular types of underlay for wood floors. Foam underlay offers good cushioning and sound insulation and is easy to install. It also helps to level out minor subfloor imperfections.

Felt Underlay: Felt underlay is made out of compressed wool or synthetic fibers and offers good sound insulation and moisture protection. Felt underlay can be used on both concrete and wooden subfloors and is an economical choice for those looking for a basic underlayment solution.

Rubber Underlay: Rubber underlay is made out of recycled rubber tires or other materials. It offers excellent sound insulation, cushioning, and moisture protection. Rubber underlays are slightly more expensive than other types of underlays but offer superior performance in areas with high humidity or moisture levels.

Cork Underlay: Cork underlays are made out of compressed cork granules or corkboard sheets. They offer excellent cushioning and sound insulation as well as some moisture protection. Cork underlays are an eco-friendly option as they are made from renewable resources.

Polyethylene Film Underlay: Polyethylene film underlays are made from thin plastic sheets that are laid directly onto the subfloor before installing the wood flooring. They offer excellent sound insulation and some degree of moisture protection but do not provide any cushioning. Polyethylene film underlays are best used in areas where there is minimal foot traffic or where additional cushioning is not necessary.

FAQs About Underlays For Wood Flooring

Q1: What type of underlay should I use for my wood floor?

A1: The type of underlay you should use depends on your specific needs and budget. Foam underlays offer good cushioning and sound insulation at an affordable price point while felt underslays offer good sound insulation and moisture protection at a slightly higher price point than foam. Rubber underslays offer superior sound insulation, cushioning, and moisture protection but come at a higher price point than foam or felt underslays. Cork underslays offer excellent cushioning, Sound insulation, and moisture protection but come at a higher price point than foam, felt, or rubber underslays. Finally, polyethylene film underslays offer excellent sound insulation and some degree of moisture protection but no cushioning and are best used in areas with minimal foot traffic or where additional cushioning is not necessary. Q2: How do I install an underlay for my wood floor?

A2: The installation process for underlays varies depending on the type of underlay you are using. Generally, foam and felt underlays should be unrolled and cut to fit the room before being laid onto the subfloor. Rubber and cork underlays should be installed in sections, while polyethylene film underlays should be laid directly onto the subfloor in one piece. It is important to make sure that all seams are properly sealed to prevent moisture from seeping through.