Troweled Epoxy Flooring

Related Images about Troweled Epoxy Flooring

Epoxy Flooring – Trowel Grade West Coast Epoxy

You even get an added advantage of protecting the concrete flooring of yours from petroleum stains and various other chemical compounds to give an additional life to the untreated floor. Epoxy floor surfaces are extremely unwilling to surface injury with their inheriting properties.

Smooth Troweled Concrete Phoenix Troweled Epoxy Flooring

The primary concept of concrete floor epoxy covering is providing flooring methods for your whole flooring problems including wet and slippery surfaces as well as surfaces harmed by chemical spillage. Epoxy flooring surfaces are favored in manufacturing environments because they provide a bit longer life to an untreated floor as well as help avoid the floor from getting spoilt by oil as well as chemical discolorations.

Projects Archive – SEQ Epoxy Flooring

It is going to seal the porous concrete surface and make it stain proof. Nonetheless, when epoxy floors cure correctly, it is going to provide your warehouse with a fresh, shiny and smooth finish, which will convey cleanliness to your workforce and clients, along with a scrub resistant surface which makes for cleaning that is easy. Epoxy flooring is an easy to set up platform with premium aesthetic appeal as well as unmatched strength.

Metallic Epoxy Photos

Residential Epoxy Flooring (6) California Custom Coatings

Colored Flake Chips Charlottetown Epoxy Flooring, Floor Sealing and Decorative Flooring

Trowel Down Epoxy Flooring – Floored Solutions

Trowel Down Epoxy Flooring – Floored Solutions

Residential Epoxy Flooring (2) California Custom Coatings

Commercial Epoxy Flooring in Sacramento, CA California Custom Coatings

Premium Cement Trowel 35 cm

Trowel Down Epoxy Flooring – Floored Solutions

Trowel Down Epoxy Flooring – Floored Solutions

Metallic Epoxy Virginia, Epoxy Coatings Decorative Concrete of Virginia (VA)

Related Posts:

- Epoxy Resin Floor Finish

- Commercial Grade Floor Epoxy

- Clear Self Leveling Floor Epoxy

- Epoxy Over Laminate Flooring

- Quikrete Floor Epoxy Reviews

- Outdoor Epoxy Resin Flooring

- Epoxy Floor Decals

- Epoxy Terrazzo Flooring Installation

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Flooring Baton Rouge

Troweled Epoxy Flooring: A Comprehensive Guide

Epoxy flooring is a popular and durable material used in many industrial and commercial settings. It provides an aesthetically pleasing, non-slip surface that is easy to clean and maintain. Troweled epoxy flooring is a type of epoxy flooring created by applying a trowel-applied mixture of two-part epoxy to a concrete surface. This type of flooring is often used in warehouses, workshops, and other areas where heavy machinery or equipment will be used. In this guide, we’ll take a closer look at the benefits, installation process, and maintenance requirements of troweled epoxy flooring.

What are the Benefits of Troweled Epoxy Flooring?

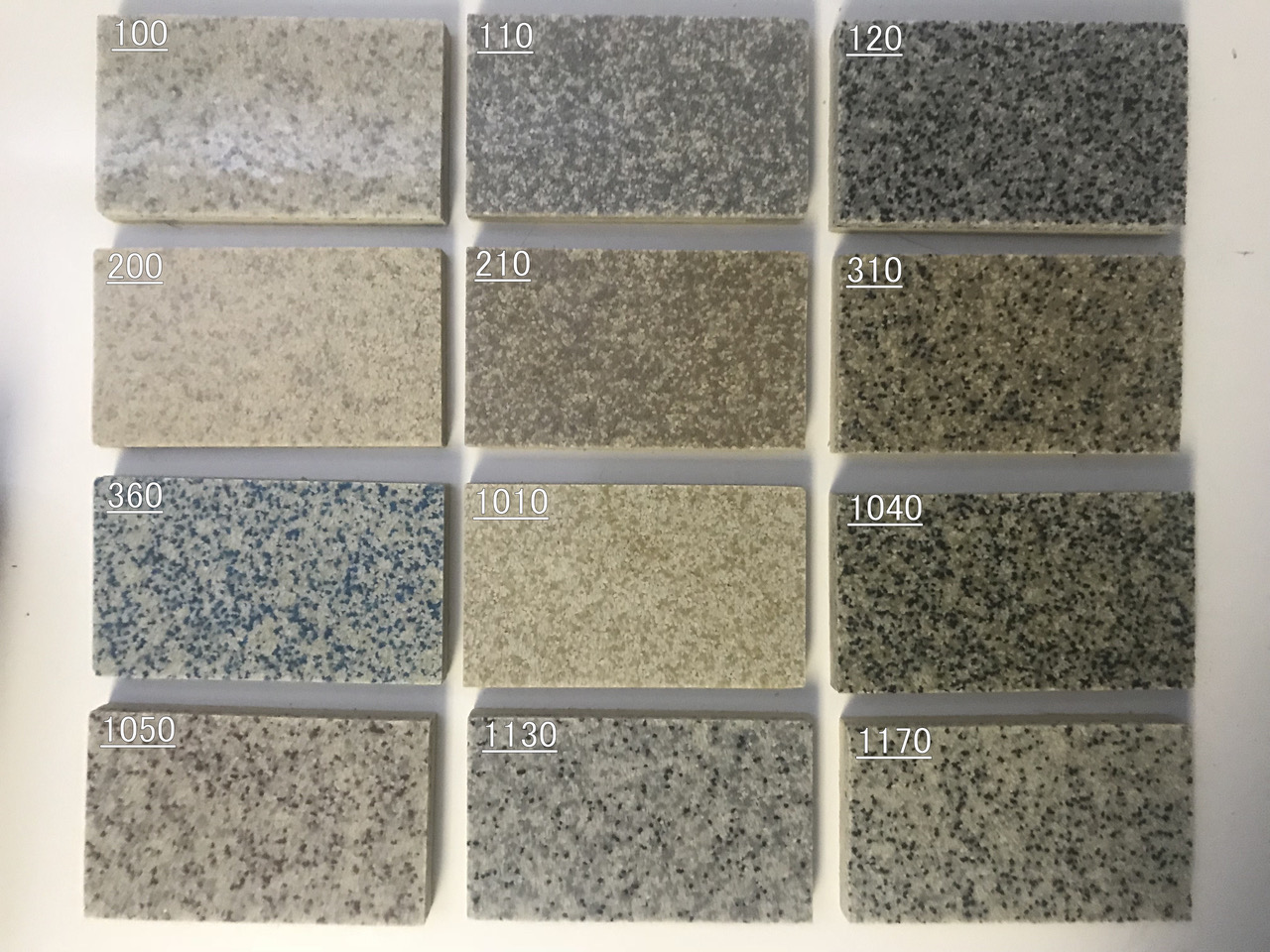

When compared to other types of flooring materials, troweled epoxy flooring offers several advantages. The most important benefit is its durability. Troweled epoxy floors are highly resistant to staining, abrasions, chemicals, and impacts. They also provide excellent slip resistance and are easy to clean with minimal maintenance required. Troweled epoxy floors are also aesthetically pleasing and can be customized with different colors and textures for a unique look.

Another benefit of troweled epoxy flooring is its cost-effectiveness. The installation process is relatively straightforward and requires minimal preparation work or specialized tools. Additionally, the finished product is highly durable and requires minimal maintenance over its lifespan which helps to save money in the long run.

How Do You Install Troweled Epoxy Flooring?

The first step in installing troweled epoxy flooring is surface preparation. The concrete surface must be completely free of dust, debris, oils, curing agents, or any other contaminants that could interfere with the adhesion of the epoxy mixture. Once the surface has been properly prepared, it’s time to mix the two-part epoxy solution according to manufacturer’s instructions.

Next comes the application phase. The mixed solution should be applied evenly with a trowel over the entire surface area being worked on. The thickness of the layer will depend on the specific type of trowel being used as well as any requirements specified by the manufacturer’s instructions. Once the entire area has been covered with the epoxy mixture it needs to be left undisturbed for at least 24 hours in order for it to cure properly before any further work can be done on it.

Finally, once the trowel-applied layer has cured you can apply decorative finishes such as colored flakes or quartz granules for a more polished look if desired. For increased protection you can also apply an additional top coat of clear sealer over the dried layer for added abrasion resistance and improved durability.

What Maintenance is Required?

Troweled epoxy floors require very little maintenance once they have been installed properly since they are highly resistant to staining and abrasion damage. Regular cleaning with a damp mop or cloth will help keep them looking like new for longer periods of time while occasional waxing may be necessary depending on how often they are used and how much traffic they experience on a daily basis. It’s also important to inspect your troweled floor periodically for any signs Of damage or wear that may require repair.

What is the cost of troweled epoxy flooring?

The cost of troweled epoxy flooring will vary depending on the size of the area and the complexity of the installation. Generally, it can range anywhere from $5 to $15 per square foot. Factors such as the type of epoxy used and the amount of preparation work required will also affect the overall cost.What are the benefits of troweled epoxy flooring?

1. Durability: Troweled epoxy flooring is highly durable and can withstand heavy traffic and wear and tear. It is also resistant to chemicals, abrasion, and staining.2. Low Maintenance: Unlike other floor coverings, troweled epoxy floors require minimal maintenance to keep them looking like new. Simply mopping or sweeping the floor occasionally will do the trick.

3. Easy Installation: Troweled epoxy floors are easy to install and can be applied directly over an existing surface such as concrete, wood, or tile without having to replace it. This saves time and money on installation costs.

4. Resistance to Slip & Fall Accidents: Troweled epoxy floors have a smooth, non-porous surface that is slip-resistant even when wet, making them ideal for commercial settings where there is a risk of slip and fall accidents.

5. Aesthetics: Troweled epoxy floors come in a variety of colors and textures that can be customized to match any décor. They also provide a high-gloss finish that can make any room look more attractive.