Tools Needed For Epoxy Floor

Related Images about Tools Needed For Epoxy Floor

Epoxy Flooring Tools, फर्श के उपकरण, फ्लोर टूल – N.S. International, Delhi ID: 19053062333

It has been implemented for a long time on industrial floors due to its toughness, durability, and resistance to oil, grease, and many other chemical substances that ruin frequent paint. Epoxy can be used to level out problem areas and make certain as well as area. You can put in epoxy flooring of places like a completed basement, the storage area of yours or maybe your outdoor deck.

How Epoxy Flooring Is Done Epoxy Floor

This forms a rigid clear plastic material which is actually good, reluctant to degradation, and that bonds extremely well to the substrate of its. So, before you implement epoxy on your flooring, it is best to examine first the state of your concrete when it generates moisture or even not. Of the three, hundred % solids epoxy is the perfect choice as it performs the best.

Industrial Epoxy Flooring Service scratchproof, Features: Water Proof, Rs 100 /square feet ID

You are able to actually apply epoxy to damaged floors, a single epoxy jacket will do! Additionally, you are going to be ready to lengthen the floors life span of yours. You can even have a floor that is built totally from epoxy. This will make the epoxy paint a viable area coat for the industrial surfaces as well. Item preparation, blending and software are compromised.

Epoxy-Coat 2-Part Bright Red High-Gloss Garage Floor Epoxy Kit (Actual Net Contents: 384-fl oz

5 Tips to Get a Great Epoxy Floor

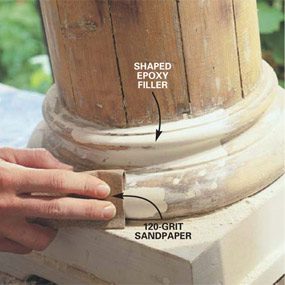

How to Use Epoxy on Wood for Repairs The Family Handyman

3 Ways to Repair an Epoxy Floor – wikiHow

3 Ways to Repair an Epoxy Floor – wikiHow

Countertop Resurfacing with Metallic Epoxy Silver and Charcoal Diy concrete countertops, Diy

Epoxy Coating Transforms Boring Flooring Angie’s List

3 Ways to Repair an Epoxy Floor – wikiHow

Interlocking Floor Tiles Floor Tile Installation

How to Design the Perfect Home Workshop – Choose Toolbox

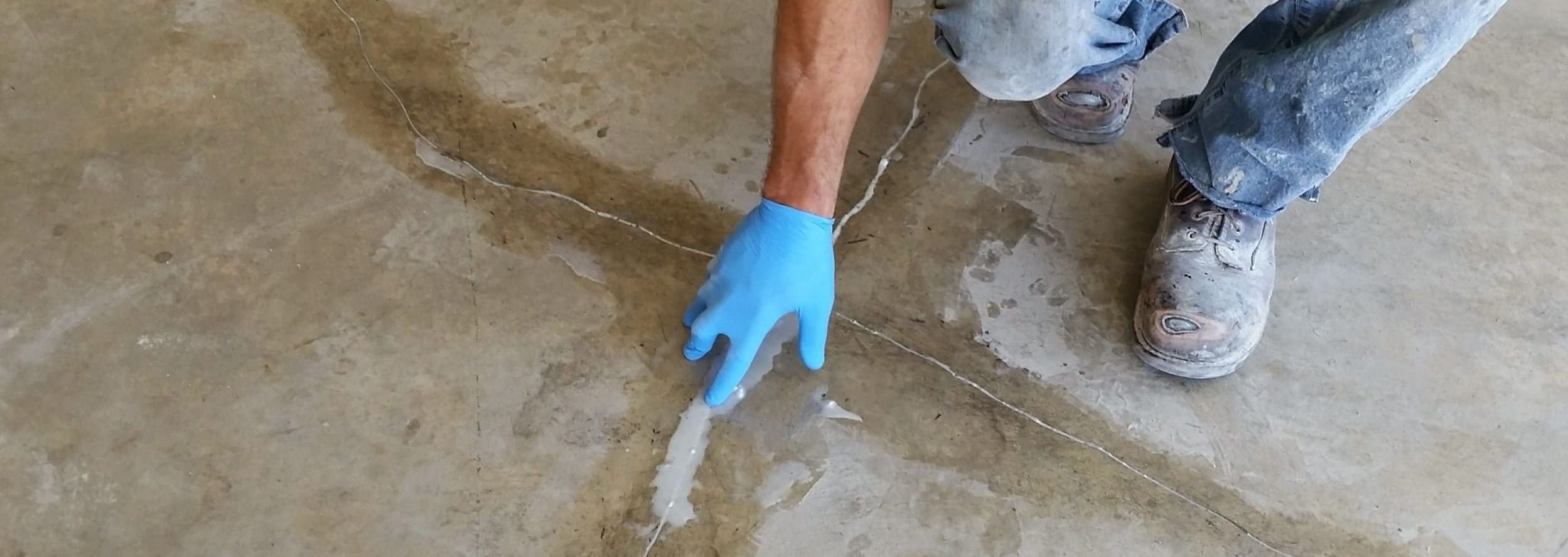

Concrete Floor Repair System Concrete Floor Supply

Related Posts:

- Epoxy Resin Floor Finish

- Commercial Grade Floor Epoxy

- Clear Self Leveling Floor Epoxy

- Epoxy Over Laminate Flooring

- Quikrete Floor Epoxy Reviews

- Outdoor Epoxy Resin Flooring

- Epoxy Floor Decals

- Epoxy Terrazzo Flooring Installation

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Flooring Baton Rouge

Epoxy flooring has become a popular choice for both residential and commercial spaces due to its durability, versatility, and aesthetic appeal. However, in order to achieve a successful epoxy floor installation, it is essential to have the right tools on hand. In this article, we will discuss the various tools needed for epoxy floor installation and provide detailed information about each one.

Surface Preparation Tools:

Before applying epoxy coating, it is crucial to properly prepare the surface to ensure adhesion and longevity of the flooring system. Some essential tools for surface preparation include:

1. Floor Grinder: A floor grinder is used to remove any existing coatings, adhesives, or contaminants from the concrete surface. It helps create a clean and porous surface for better adhesion of the epoxy coating.

FAQs:

Q: Do I need to grind my concrete floor before applying epoxy?

A: Yes, proper surface preparation, including grinding the concrete floor, is essential for a successful epoxy floor installation.

2. Shot Blaster: Shot blasting is another method of preparing the concrete surface by propelling steel shots at high velocity to remove contaminants and create a rough profile. This tool is particularly useful for larger areas or heavily contaminated floors.

FAQs:

Q: Can I use a shot blaster instead of a floor grinder for surface preparation?

A: While shot blasting can be an effective method for surface preparation, it may not be suitable for all types of concrete floors. It is best to consult with a professional to determine the most appropriate method for your specific project.

3. Floor Scraper: A floor scraper is used to remove stubborn coatings or adhesives that cannot be removed by grinding or shot blasting. It helps ensure a clean and smooth surface before applying the epoxy coating.

FAQs:

Q: Can I use a regular scraper instead of a floor scraper?

A: While a regular scraper may work for small areas or light coatings, a floor scraper is specifically designed for heavy-duty applications and can save time and effort in larger projects.

Application Tools:

Once the surface has been properly prepared, it is time to apply the epoxy coating. Some essential tools for epoxy application include:

1. Squeegee: A squeegee is used to spread the epoxy resin evenly across the floor surface. It helps achieve a smooth and uniform coating thickness for optimal performance and appearance.

FAQs:

Q: Can I use a roller instead of a squeegee to apply epoxy?

A: While a roller can be used for some types of epoxy coatings, a squeegee is preferred for achieving an even coat and avoiding roller marks on the finished floor.

2. Mixing Paddle: A mixing paddle attached to a drill is used to thoroughly mix the epoxy resin and hardener before application. Proper mixing ensures that the components are fully blended for maximum strength and durability.

FAQs:

Q: Can I mix epoxy resin and hardener by hand?

A: Hand mixing may not achieve thorough blending of the components, leading to uneven curing and compromised performance of the epoxy coating. Using a mixing paddle attached to a drill is recommended for consistent results.

3. Spike Shoes: Spike shoes are worn by installers during epoxy application to prevent footprints on the wet coating. They help distribute weight evenly and minimize disruptions to the freshly applied epoxy.

FAQs:

Q: Do I need spike shoes if I am using a roller instead of a squeegee?

A: Spike shoes are recommended regardless of the application method to avoid leaving marks or indentations on The epoxy coating. They provide stability and help maintain a smooth surface finish.

4. Mixing Container: A mixing container is used to combine the epoxy resin and hardener. It should be clean, dry, and large enough to accommodate the necessary amount of material for the project.

FAQs:

Q: Can I reuse a mixing container for multiple batches of epoxy?

A: It is not recommended to reuse a mixing container for multiple batches of epoxy as it may lead to contamination and affect the quality of the coating. Use a new container for each batch to ensure proper mixing and application.

5. Paint Roller: A paint roller can be used for applying epoxy primer or topcoat in areas where a squeegee may not reach easily. It helps achieve an even application and smooth finish on the floor surface.

FAQs:

Q: Can I use any type of paint roller for applying epoxy?

A: It is recommended to use a high-quality roller designed for epoxy coatings to ensure proper application and avoid lint or fibers from getting trapped in the coating. Choose a roller with the appropriate nap length for your specific project.

In conclusion, having the right tools for surface preparation and epoxy application is essential for achieving a successful and durable epoxy flooring system. By using the appropriate tools and following best practices, you can ensure a professional finish that meets your performance and aesthetic requirements.