Suspended Concrete Floor Slab Construction

Related Images about Suspended Concrete Floor Slab Construction

Concrete slab floor construction BRANZ Renovate

You will have a convenient subfloor for epoxy, tile, carpeting, or whatever surface you want whether you ever get tired of the bare concrete flooring look. This unquestionably gets to be the reason why the need for polished concrete floors nowadays has skyrocketed, and men and women are opting for it as an economical and innovative choice outdoor & indoor.

CONCRETE FLOOR SLAB CONSTRUCTION

You will find a range of diverse techniques you can use to concrete flooring to produce gorgeous decorative floors made for both the office of yours and your house. In the event that you desire to get a tank over it, when poured, concrete can take it. With acid stained concrete floor, you’ve alternatives available to meet the design needs of yours.

Beodom Making of Amadeo’s first floor slab with precast beams and ceiling bricks

However, it is essential for each home owner who is utilizing the polished concrete floor surfaces to find out how the polished floor is actually achieved when all is said as well as done. Acid Stain concrete floorings have time and again proven the reliability of theirs with regards to cost efficiency, durability and the sturdiness of the flooring.

What Is Formwork For Slab? My Decorative

PDH Quiz – Guide for Concrete Floor and Slab Construction Online PDH Courses Engineering

Stormwater Management

Concrete Stairs ¦ Precast Stair Units ¦ Concrete Landing Slab

Installation of reinforced concrete floor slab

Reinforced concrete precast core floor slab – DEMIDEC – Cornish Concrete Products

In Situ Concrete Floor Slab – Carpet Vidalondon

Typical Slab Reinforcement.AVI – YouTube

Structural Concrete Design of a Garage Floor Allows for a Full Basement Below – YouTube

Defining Concrete Repair: Parking/Plaza Slab Strengthening Concrete Construction Magazine

SLAB ON GRADE- slab foundation concrete finished floor Slab-on-grade Foundation Javítás

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Suspended Concrete Floor Slab Construction

Suspended concrete floor slab construction is a common form of building construction in which the floors of a structure are built on an elevated frame of steel or concrete. This type of construction is often used in commercial buildings, industrial facilities, and other large-scale structures. It is also sometimes used in residential buildings, though it is more expensive than traditional framing methods. Suspended concrete floor slab construction offers many advantages over traditional methods and can be customized to meet the specific needs of each project, making it a popular choice for many architects and engineers.

Advantages of Suspended Concrete Floor Slab Construction

Suspended concrete floor slab construction offers a number of advantages when compared to traditional framing methods. One of the major benefits is that it eliminates most of the labor-intensive work required in traditional framing, such as constructing the floor joists and laying down the plywood or other materials used for the flooring. This allows for faster construction times and fewer laborers on the job site. Additionally, suspended concrete floor slabs provide better insulation than traditional methods, resulting in lower energy costs over time. Finally, suspended concrete floors are extremely durable and can last for decades with minimal maintenance.

Installation Process for Suspended Concrete Floor Slab Construction

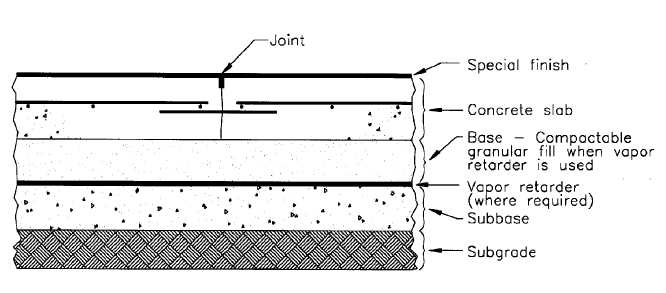

Installing a suspended concrete floor slab requires careful planning and precise execution. First, the foundation must be properly prepared, which typically involves digging out an area for the footings to be placed in and compacting the soil beneath them. Once this is done, steel reinforcing bars (rebar) are placed in the footings and then tied together to create a frame for the slab. After this, concrete is poured into the frame and allowed to cure before being leveled with a screed board or trowel. Once this process is finished, any additional layers such as insulation or vapor barriers can be added before covering with final flooring materials such as tile or carpeting.

Finishing Touches for Suspended Concrete Floor Slab Construction

Once all of the structural elements have been installed, there are still some finishing touches that must be taken care of before a suspended concrete floor slab can be considered complete. For one thing, any exposed edges that may pose a tripping hazard must be sealed off with a sealant such as polyurethane or epoxy. Additionally, any visible seams between individual slabs must be filled in with grout or mortar to ensure a smooth surface when walking on it. Finally, any electrical wiring or plumbing components must be properly routed through conduits before being connected to their outlets or fixtures.

FAQs About Suspended Concrete Floor Slab Construction

Q: How long does it take to install a suspended concrete floor slab?

A: The installation process for a suspended concrete floor slab typically takes 2-3 days depending on the size and complexity of the project. The amount of time required can vary greatly due to factors such as weather conditions and delays caused by unforeseen circumstances such as access issues or utility supply problems.

Q: Are there any special considerations that need to be taken into account when installing a suspended concrete floor slab?

A: Yes, there are several factors that should be taken into consideration when installing a suspended concrete floor slab including proper preparation of the foundation; use Of adequate reinforcement; proper curing of the concrete; and installation of any necessary insulation, vapor barriers, or electrical wiring. Additionally, the slab should be checked for levelness and any exposed edges should be sealed off with a sealant.

What are the advantages of constructing a suspended concrete floor slab?

1. Cost-Effective: Suspended concrete floor slabs are an affordable option compared to other structural systems. They require less material and labour, resulting in lower construction costs.

2. Durability: Suspended concrete floor slabs are highly durable and can withstand heavy loads. This makes them ideal for high-traffic areas such as commercial buildings.

3. Versatility: Suspended concrete floor slabs can be designed to accommodate a wide variety of architectural requirements and finishes, making them suitable for a variety of applications.

4. Fire Resistance: Suspended concrete floor slabs offer excellent fire resistance due to their dense composition, making them a great choice for public spaces such as shopping centres, schools, and hospitals.

5. Acoustic Performance: Suspended concrete floors are highly sound absorbing, reducing noise levels inside a building.