Spiked Rollers For Epoxy Flooring

Related Images about Spiked Rollers For Epoxy Flooring

Epoxy Flooring Tools, फर्श के उपकरण, फ्लोर टूल – N.S. International, Delhi ID: 19053062333

They are not difficult to use and typically inexpensive. The nice thing about this kind of covering is that you can combine it as per the requirements of yours. If your business is considering floor plans for new design, or wanting to renovate the old style, epoxy floors could be very beneficial to your plans.

Epoxy Flooring Service, For Roller and Spatula, Grade Standard: Industrial, Rs 35 /square feet

Epoxy flooring is additionally very painless to clean because there's nothing for contaminants to hang onto. These may be offered the sought-after styles after blending several dyes agent to them. And furthermore the epoxy flooring paint is so easy to use and keep. It is not very pricey and will outlast various other floor coatings. In reality, it's smarter than almost all other choices.

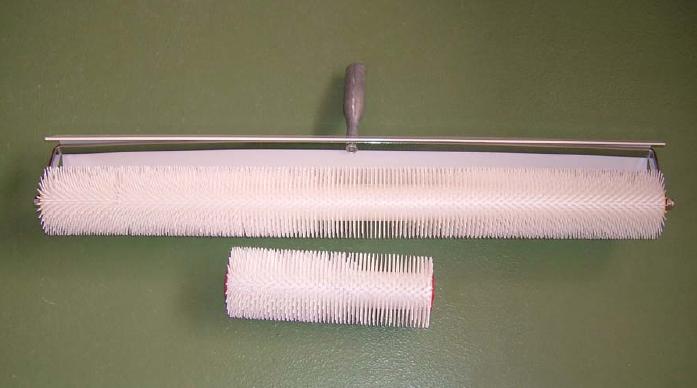

Floor Leveling Spiked Roller – Carpet Vidalondon

With good area planning, manufacturing epoxy floor covering software enjoy a high possibility of success. It lays very well on a lot of kinds of surfaces as metal, concrete, wood and tile and is resistant to most harsh chemicals making for a durable and some style and long-lasting surface might even be added to the epoxy for a little bit of flare. Epoxy concrete paints are highly durable and will stand up to pressure that is high.

Spikey Roller 12 inch Floor preparation, Laminate flooring, Flooring

Flooring Application Tools

Cement Self Leveling Kit Epoxy Floor Paint Roller Blade Spike Expedited Shipping eBay

Epoxy Spiked Roller (China Manufacturer) – Hand Tools – Tools Products – DIYTrade China

XL Spiked Roller – XL Spiked Roller Floor Coating Applicators – Nour

AM28 Air Paint Mixer + S/S Paddle

High Quality 20" Spike Roller Flooring Defoaming Paint Roller – Buy Defoaming Paint Roller,Spike

7" Hard Back ATX Paint Stripping Disc

Stainless Spiral Paddles 4¾", 5½" & 6¼"

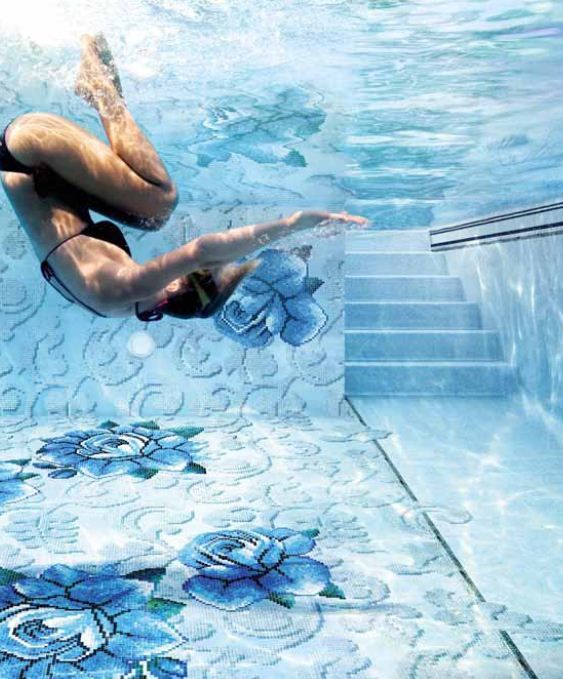

Make a 3D flooring for your swimming pool with epoxy paint

18" SpeedSqueegee, 15-20 mil blade • Ultra Durable Technologies, Inc.

Related Posts:

- Epoxy Resin Floor Finish

- Commercial Grade Floor Epoxy

- Clear Self Leveling Floor Epoxy

- Epoxy Over Laminate Flooring

- Quikrete Floor Epoxy Reviews

- Outdoor Epoxy Resin Flooring

- Epoxy Floor Decals

- Epoxy Terrazzo Flooring Installation

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Flooring Baton Rouge

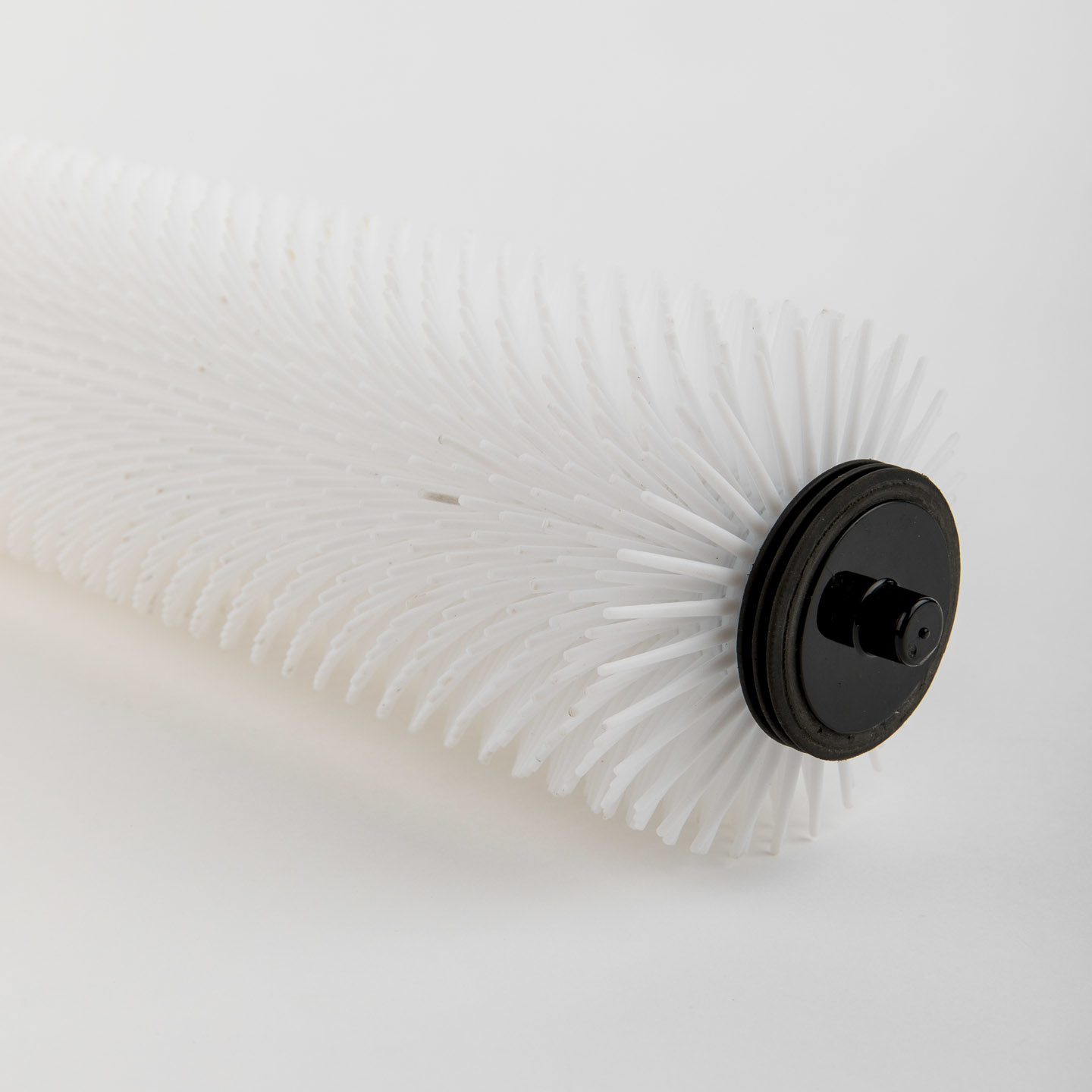

When it comes to applying epoxy flooring, using spiked rollers is a common practice that can greatly improve the overall finish of the floor. Spiked rollers are tools with small spikes or pins attached to a roller that help to evenly distribute the epoxy resin and remove any air bubbles that may be trapped in the surface. This results in a smoother and more professional-looking finish that is also more durable and long-lasting.

**Benefits of Using Spiked Rollers**

One of the main benefits of using spiked rollers for epoxy flooring is that they help to ensure a consistent thickness of the epoxy resin across the entire surface. This is important because an uneven application can lead to weak spots in the floor that are more prone to damage over time. By using a spiked roller, you can achieve a uniform thickness that will provide better protection for your floor.

Another advantage of using spiked rollers is that they help to eliminate air bubbles that may be present in the epoxy resin. Air bubbles can cause imperfections in the finish of the floor and weaken its overall integrity. By rolling out the epoxy with a spiked roller, you can effectively release any trapped air and create a smooth, bubble-free surface.

Using a spiked roller also helps to improve the adhesion of the epoxy resin to the substrate. The spikes on the roller help to push the resin into any cracks or crevices in the surface, ensuring that it fully bonds with the underlying material. This results in a stronger and more durable finish that will last for years to come.

Lastly, spiked rollers are easy to use and require minimal effort to achieve professional results. Simply apply the epoxy resin as directed, then roll over the surface with the spiked roller to evenly distribute the material and remove any imperfections. This simple tool can make a big difference in the quality of your epoxy flooring project.

**Choosing the Right Spiked Roller**

When selecting a spiked roller for your epoxy flooring project, there are a few key factors to consider. The size and length of the spikes on the roller will determine how well it can penetrate and distribute the epoxy resin. For thicker coatings, longer spikes may be necessary to ensure proper coverage.

Additionally, consider the width and diameter of the roller itself. A wider roller will cover more surface area in less time, while a smaller diameter roller may be easier to maneuver in tight spaces. Choose a roller that is comfortable for you to use and fits well within your project requirements.

It’s also important to consider the material of the roller itself. Some rollers are made from materials like nylon or polypropylene, which are durable and resistant to chemicals commonly used in epoxy coatings. Make sure to choose a roller that is compatible with your specific epoxy resin formulation.

Lastly, consider whether you need a spiked roller with an adjustable handle or frame. This can make it easier to reach different areas of your flooring project and provide better control over the application process.

**Proper Techniques for Using Spiked Rollers**

To achieve optimal results with your spiked roller, there are some key techniques to keep in mind during application. First, make sure that you mix your epoxy resin according to manufacturer instructions before starting. Proper mixing will ensure that all components are evenly distributed for best results.

Next, pour out your mixed epoxy onto the floor in small sections at a time. Use a squeegee or trowel to spread out the material evenly before rolling over it with your spiked roller. Work quickly but carefully to prevent premature curing of the epoxy.

When rolling out the epoxy, move The roller in a back and forth motion, overlapping each pass slightly to ensure even coverage. Avoid pressing too hard on the roller, as this can cause the spikes to dig too deeply into the epoxy and create uneven patches. Instead, apply gentle pressure and let the spikes do the work of distributing the material.

After rolling out the epoxy, allow it to cure according to manufacturer instructions before applying any additional coats or finishes. Clean your spiked roller thoroughly with solvent or soap and water after each use to prevent buildup of dried epoxy resin.

In conclusion, using a spiked roller is an essential tool for achieving professional results when applying epoxy flooring. By choosing the right roller for your project, following proper techniques during application, and maintaining your equipment, you can ensure a smooth and durable finish that will last for years to come. **Choosing the Right Spiked Roller for Epoxy Flooring**

When it comes to applying epoxy flooring, using a spiked roller is key to achieving a smooth and even finish. Spiked rollers are designed to help distribute epoxy resin evenly across the surface, ensuring proper adhesion and coverage. However, not all spiked rollers are created equal, so it’s important to choose the right one for your specific project needs.

One of the most important factors to consider when selecting a spiked roller is the length and density of the spikes. The length of the spikes will determine how deeply they penetrate the epoxy resin, while the density will affect how evenly the material is distributed.

For thin coatings, shorter spikes may be sufficient, while thicker coatings may require longer spikes to ensure proper coverage. It’s important to choose a roller with spikes that are appropriate for the thickness of the epoxy resin you are using.

Furthermore, consider the width and diameter of the roller itself. A wider roller will cover more surface area in less time, while a smaller diameter roller may be easier to maneuver in tight spaces. Choose a roller that is comfortable for you to use and fits well within your project requirements.

Additionally, consider the material of the roller. Some rollers are made from durable materials like nylon or polypropylene, which are resistant to chemicals commonly used in epoxy coatings. Make sure to choose a roller that is compatible with your specific epoxy resin formulation.

Finally, consider whether you need a spiked roller with an adjustable handle or frame. This can make it easier to reach different areas of your flooring project and provide better control over the application process.

Overall, choosing the right spiked roller for your epoxy flooring project is essential for achieving professional results. By considering factors such as spike length and density, roller width and diameter, material compatibility, and handle adjustability, you can ensure a smooth and even finish that will last for years to come.

**Proper Techniques for Using a Spiked Roller with Epoxy Flooring**

Once you have selected the right spiked roller for your epoxy flooring project, it’s important to use proper techniques during application to ensure a successful finish. Here are some tips to help you achieve the best results:

1. Start by preparing your surface properly before applying epoxy resin. Make sure the area is clean, dry, and free of any debris or contaminants that could affect adhesion.

2. Mix your epoxy resin according to the manufacturer’s instructions, ensuring it is well blended before application.

3. Pour the epoxy resin onto the floor in small sections, using a squeegee or trowel to spread it evenly across the surface.

4. Use the spiked roller to distribute the epoxy resin in a back and forth motion, making sure to overlap each pass slightly to avoid leaving gaps or streaks.

5. Apply even pressure while rolling to ensure that the spikes penetrate the resin and distribute it evenly across the surface.

6. Work quickly but carefully, as epoxy resin has a limited working time before it begins to cure.

7. Avoid overworking the epoxy resin with the spiked roller, as this can cause air bubbles to form in the finish.

8. Allow the epoxy flooring to cure according to the manufacturer’s instructions before applying any additional coats or finishes.

9. Clean your spiked roller thoroughly with solvent or soap and water after each use to prevent buildup of dried epoxy resin.

In conclusion, using a spiked roller is an essential tool for achieving professional results when applying epoxy flooring. By choosing the right roller for your project, following proper techniques during application, and maintaining your equipment, you can ensure a smooth and durable finish that will last for years to come.