Skim Coat Garage Floor

Related Images about Skim Coat Garage Floor

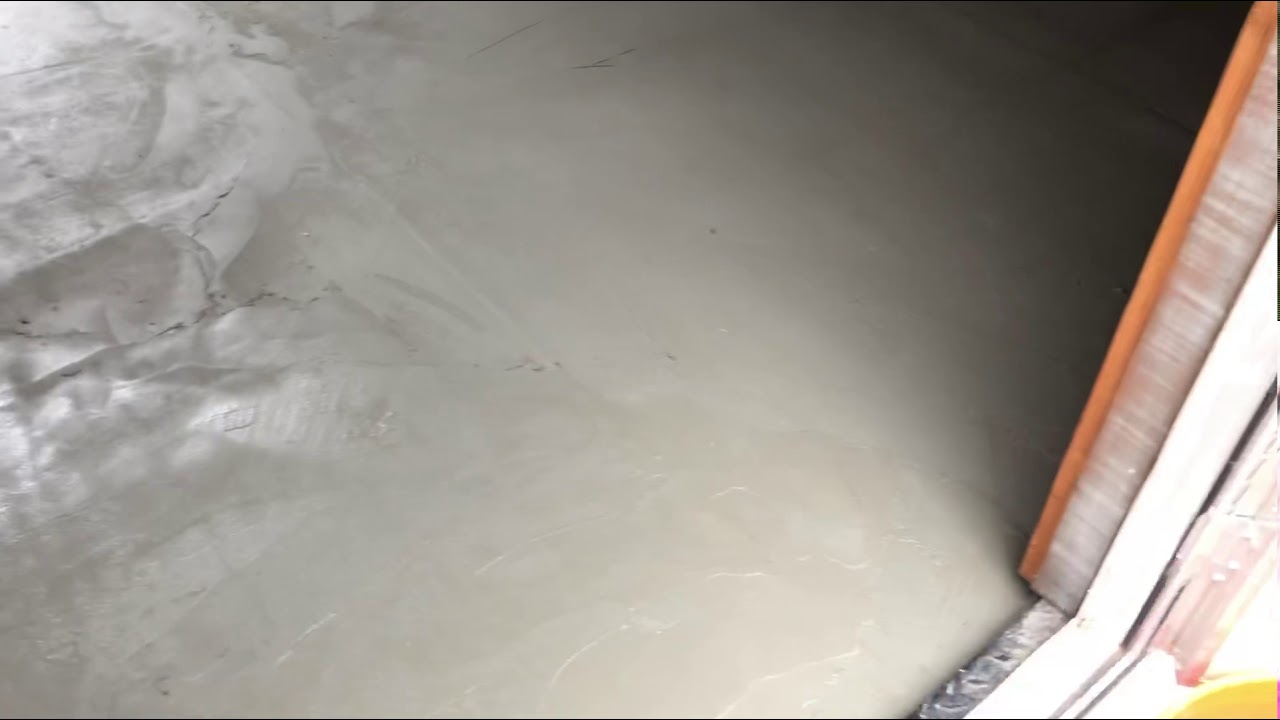

Skim Coat Concrete Floor For Tile – Flooring : Home Design Ideas #a5Pjr5d8P999300

They develop a seamless appearance in a smaller garage or even is usually used solely under the automobile at a bigger garage. On a regular basis maintaining the floor of yours is crucial, but quite simple. Due to this reason, there is an increasing demand in keeping garage floors a tidier place. You are able to also paint the garage walls or possibly insert a border strip of wallpaper to match the flooring.

Skim coat floor: part 4 of 4 – YouTube

There is simply something about this classic look that never appears to age or even get dull. It will increase the life of the mat and it will go longer before having to be changed. Most garage flooring is made from concrete and it's typically cracked in locations and just not so decorative in appearance. In the contrary, the tire can cool down and solidify all over again had it been in connection with the concrete floor.

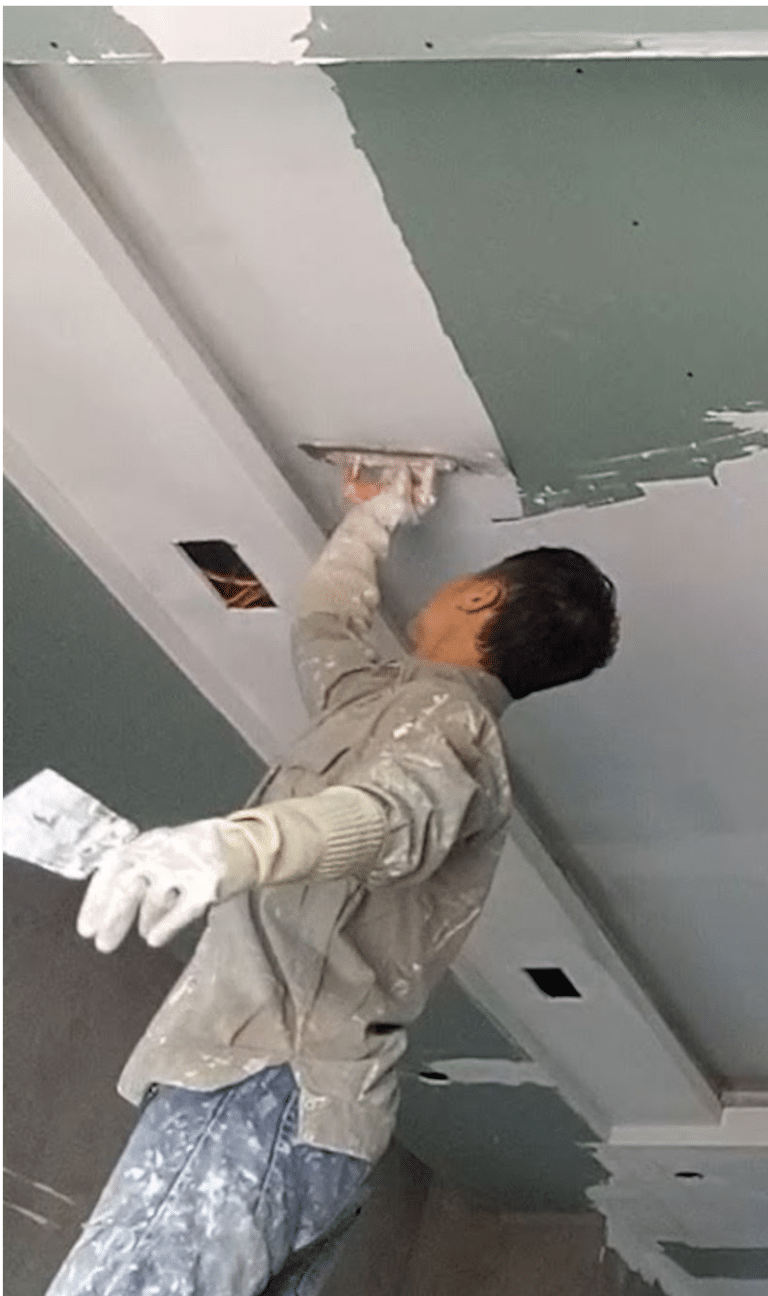

Skim Coat Wall KL & Selangor Delivers Rapid-response Service

Maybe the simplest way to enhance your garage is by the usage of floor mats designed to cover regardless of being part or even most of the floor area. I've seen this paint type on storage area flooring before and it looks really good. It does not take up more than a week's time to do the task. Occasionally this causes a problem, there are times when it doesn't.

Skim Coat Ceiling KL & Selangor Fixing Ceiling

DY-Mark 8L Clear Epoxy Garage Floor Coating Kit Bunnings Warehouse

Skim Coat KL & Selangor Responsible Painter

5kg Karndean Flooring Skim Coat Compound Self Levelling Latex Floor Screed eBay

Ways To Take Your Garage To the Next Level – 2021 Guide – Garden, Sport & Outdoor Tools

Garage Floor Coating Epoxy Flooring Company Corona, CA

How to Skim Coat Concrete Hunker Concrete repair products, Concrete patio resurfacing

The Raw House Project : { Skim Coating }

Finishing clear-coat on garage floor – YouTube

How to coat your garage floor – How to with abe

Commercial Flooring Gallery Garage Store

Related Posts:

- Valspar Garage Floor

- Self Levelling Garage Floor Paint

- Valspar Epoxy Garage Floor Paint

- Garage Floor With Flakes

- Garage Floor Sealer Vs Epoxy

- Bondall Garage Floor Paint Review

- How To Polish Concrete Garage Floor

- Garage Floor Paint Do It Yourself

- Drymate Garage Floor Mat Review

- Modular Interlocking Garage Floor Tiles

Skim coating a garage floor is a popular option for homeowners looking to improve the appearance and durability of their concrete flooring. This process involves applying a thin layer of cement-based material to the surface of the floor, creating a smooth and level finish. In this article, we will discuss the benefits of skim coating a garage floor, the steps involved in the process, and some frequently asked questions about this technique.

Benefits of Skim Coating a Garage Floor

Skim coating offers several advantages for garage floors. First and foremost, it can dramatically improve the appearance of the floor by covering up imperfections such as cracks and stains. The smooth finish created by skim coating also makes the floor easier to clean and maintain, as dirt and debris can be easily swept or hosed away. Additionally, skim coating can help protect the underlying concrete from damage caused by moisture, chemicals, and heavy traffic.

Another benefit of skim coating is that it can provide a more comfortable surface for walking and working in the garage. The smooth finish reduces the risk of tripping or slipping on uneven or rough areas of the floor. This can be especially important in a garage where tools, equipment, and other items are often moved around.

Steps to Skim Coat a Garage Floor

The process of skim coating a garage floor involves several steps to ensure a successful result. Here is an overview of the typical steps involved:

1. Preparation: Before starting the skim coating process, it is essential to thoroughly clean the garage floor to remove any dirt, oil, grease, or other contaminants. Any existing coatings or sealants should also be removed to ensure proper adhesion of the skim coat.

2. Repair: Inspect the floor for any cracks, holes, or other damage that needs to be repaired before skim coating. These areas should be filled with an appropriate patching material and allowed to dry completely before proceeding.

3. Priming: Apply a primer to the entire surface of the garage floor to promote adhesion and ensure a strong bond between the concrete and the skim coat material.

4. Mixing: Mix the skim coat material according to the manufacturer’s instructions, making sure to achieve a smooth and lump-free consistency.

5. Application: Using a trowel or squeegee, spread a thin layer of skim coat material evenly over the surface of the garage floor. Work in small sections at a time to ensure an even application and avoid drying out before smoothing.

6. Smoothing: Once the skim coat material has been applied, use a steel trowel or squeegee to smooth out any ridges or imperfections in the surface. Work quickly but carefully to achieve a flat and level finish.

7. Curing: Allow the skim coat material to dry and cure according to the manufacturer’s instructions before walking or driving on it. This typically takes 24-48 hours depending on temperature and humidity levels.

Frequently Asked Questions

Q: How long does it take to skim coat a garage floor?

A: The time it takes to complete a skim coating project will depend on factors such as the size of the garage floor, condition of the existing concrete, and weather conditions. On average, it may take 2-3 days from preparation to final curing.

Q: Can I DIY skim coat my garage floor?

A: While DIY skim coating is possible for those with some experience in concrete work, it is recommended to hire a professional contractor for best results. Proper preparation, mixing, application, and finishing are Crucial to ensure a successful skim coating job, and a professional contractor will have the expertise and tools needed to achieve a high-quality finish.

Q: How long does a skim coat last on a garage floor?

A: With proper preparation and maintenance, a skim coat can last for many years on a garage floor. Regular cleaning, sealing, and avoiding harsh chemicals or heavy equipment can help prolong the lifespan of the skim coat.

Q: Can I drive on a skim coated garage floor?

A: It is recommended to avoid driving on a freshly skim coated garage floor for at least 24-48 hours to allow the material to properly cure and harden. Once fully cured, the skim coat should be able to withstand vehicle traffic without damage.

In conclusion, skim coating a garage floor can provide a durable and attractive surface that is easy to maintain and enhances safety. By following the steps outlined above and seeking professional help when needed, homeowners can enjoy the benefits of a smooth and functional garage floor for years to come. Remember to always follow the manufacturer’s instructions for the specific skim coat material being used, and take proper safety precautions when working with concrete materials. With careful preparation and attention to detail, you can achieve a professional-looking finish that will enhance the overall appearance and functionality of your garage floor. If you have any doubts or concerns, it is always best to consult with a professional contractor for guidance.