Prefabricated Concrete Floor Systems

Related Images about Prefabricated Concrete Floor Systems

Concrete Plant Precast Technology

The primary reason is the fact that these floors are power efficient flooring options and will last for a lot of years. The hardest part is waiting: When the full concrete floor is completed, you still need to hold off auto parking the automobile on it for another seventy two hours. There are concrete floors which look plain and gray just love those found in factories and garages.

Pin on Structural systems

While concrete polishing shines concrete to an excessive gloss, it opens the pores in the concrete. Polished concrete floors makes perfect sense for business people which need an enticing floor which does not have to be waxed with the end of each day. Polished concrete flooring is an affordable way to other floorings and can offer you exactly the same mirror as finish.

Heavy Reinforced Concrete Floor Case Study – Premier Pits

On top of a mirror-like shine, concrete flooring might be spruced up with embedded other, grids, images, lines, and patterns designs. They impart a high-class richness that cannot be attained by any other flooring. With more properties being made in a contemporary style, concrete polishing floors is actually growing in leaps and bounds. Abrasive pads file down the best surface of the concrete.

Contact Us Concrete Structures & Floors

Passive House: Concrete Floors

Concrete Plant Precast Technology

Suspended Concrete Floor Systems Nz – Carpet Vidalondon

Tarmac TermoDeck paired with glulam timber structure at BGS offices Timber structure, Timber

Stand-alone recreational and sanitary facilities – Call 205-980-4565

Concrete Plant Precast Technology

Shower Floor Pans Kits – Vintalicious.net

Services – Floorspan

CONCRETE PRODUCTS – Precast Concrete Sales Company

Precast Concrete Installation – Floorspan – Large Developments

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

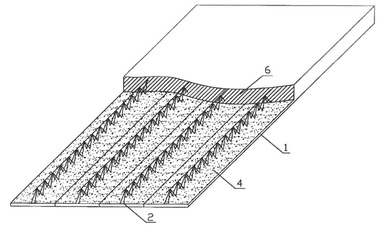

Prefabricated concrete floor systems have become increasingly popular in construction projects due to their efficiency, durability, and cost-effectiveness. These systems consist of precast concrete panels that are manufactured off-site and then transported to the construction site for installation. Prefabricated concrete floor systems offer a number of benefits, including faster construction times, reduced labor costs, and improved quality control.

Benefits of Prefabricated Concrete Floor Systems

One of the main advantages of prefabricated concrete floor systems is their speed of installation. Since the panels are manufactured off-site, they can be installed quickly and efficiently once they arrive at the construction site. This can help to reduce overall construction time and allow for projects to be completed more quickly.

Another benefit of prefabricated concrete floor systems is their cost-effectiveness. By manufacturing the panels in a controlled environment, manufacturers are able to reduce material waste and optimize production processes, resulting in lower costs for both materials and labor. This can help to make projects more affordable without sacrificing quality or durability.

In addition to their speed and cost savings, prefabricated concrete floor systems also offer improved quality control. Since the panels are manufactured in a factory setting, manufacturers can closely monitor production processes and ensure that each panel meets strict quality standards. This can help to reduce the risk of defects or errors during installation and improve overall project outcomes.

Lastly, prefabricated concrete floor systems are known for their durability and strength. The panels are made from high-quality concrete materials that are designed to withstand heavy loads and resist wear and tear over time. This can help to extend the lifespan of the building and reduce maintenance costs in the long run.

Common Mistakes to Avoid

– Not properly preparing the site before installation: It’s important to ensure that the site is properly leveled and free of debris before installing prefabricated concrete floor systems. Failing to do so can result in uneven or unstable floors.

– Ignoring manufacturer guidelines: Each manufacturer may have specific guidelines for installation and maintenance of their prefabricated concrete floor systems. Ignoring these guidelines can lead to issues with performance or durability.

– Overlooking proper sealing and waterproofing: Proper sealing and waterproofing measures should be taken to protect prefabricated concrete floor systems from moisture damage over time. Failing to do so can result in cracks or deterioration.

– Not hiring experienced professionals for installation: Installing prefabricated concrete floor systems requires specialized knowledge and skills. Hiring inexperienced or unqualified professionals can lead to errors or improper installation.

FAQs

1. Are prefabricated concrete floor systems suitable for residential buildings?

Yes, prefabricated concrete floor systems can be used in residential buildings as well as commercial and industrial projects. They offer a range of benefits such as speed of installation, cost-effectiveness, and durability.

2. How long do prefabricated concrete floor systems last?

Prefabricated concrete floor systems are designed to be durable and long-lasting, with a lifespan of 50 years or more depending on maintenance practices.

3. Can prefabricated concrete floor systems be customized?

Yes, prefabricated concrete floor systems can be customized to meet specific project requirements in terms of size, shape, finish, and design.

4. Are prefabricated concrete floor systems environmentally friendly?

Prefabricated concrete floor systems can be considered environmentally friendly due to their efficient use of materials, reduced waste during production, and potential for energy savings during construction.

5. What maintenance is required for prefabricated concrete floor systems?

Regular cleaning and Maintenance of prefabricated concrete floor systems are recommended to ensure their longevity and performance. This may include sweeping or vacuuming to remove debris, mopping with a mild detergent to clean the surface, and resealing as needed to protect against moisture damage. Additionally, any cracks or damage should be repaired promptly to prevent further issues.

In conclusion, prefabricated concrete floor systems offer a range of benefits for various types of buildings. By avoiding common mistakes and following proper installation and maintenance practices, these systems can provide a durable and long-lasting flooring solution. With proper care and attention, prefabricated concrete floor systems can continue to perform well for many years to come.