Precast Concrete Floor Construction Details

Related Images about Precast Concrete Floor Construction Details

precast floor on steel frame floor sections – Google Search Structures-Pre-cast Concrete

A spot remover specifically formulated for concrete floor, similar to those offered at professional janitorial source companies, can help. By comparison, a polished concrete floor, which is highly resistant to scuffs and stains, could be simply mopped when necessary. The finished result is a very uniform surface, joints are slightly noticeable.

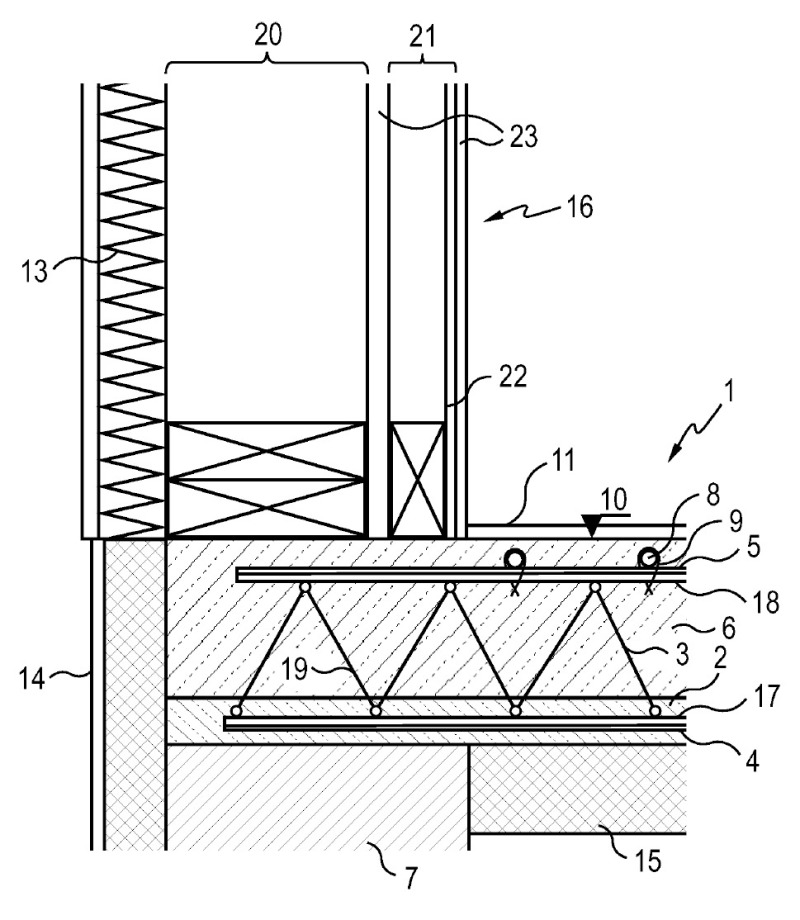

Patent US20130074433 – Precast concrete structures, precast tilt-up concrete structures and

Applying concrete floor coating to your floor appears to be as quick as painting walls, but just like painting, it involves a pro telephone call. Stained concrete for your flooring is offering options which are abundant choices for interiors such as virtually limitless designs in addition to health advantages.

Concrete Plant Precast Technology

Concrete floors are functional and practical. In the summer season, the concrete floors absorbs moisture from the earth to keep it cool. In the first place, there is an excellent sensation of affordability in relation to these concrete floors, a great deal that many individuals today notice them while the best option concerning flooring.

Concrete Stairs, Precast Stair Units, Concrete Landing Slab

Precast Concrete Detailing Precast Concrete Tilt-up Panels Detailing Precast Detailing

PRECAST and TILT-UP CONCRETE – Engineer-Educators.com

Beam & Blocks Products About Us Rackham Housefloors

Installing Foreverhome Precast Concrete Wall Panels Foreverhome

Foundations: original details BRANZ Renovate

World Housing Encyclopedia -WHE

Double Tees – SPI MIAMI – STRUCTURAL PRESTRESSED INDUSTRIES – PRECAST CONSTRUCTION SYSTEMS

DETAIL 4/2016 – Concrete Construction by DETAIL – Issuu

Modern Concrete Construction Manual by DETAIL – Issuu

Tilt-Up Potential Expressed : TILT-UP TODAY – A publication of the Tilt-Up Concrete Association

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction

Precast concrete floor construction is a popular method of constructing floors that are both durable and cost-effective. Precast concrete floor construction involves the use of precast concrete slabs, which are held together by steel or reinforced concrete beams, creating a strong and rigid frame for the floor. This type of construction has numerous advantages including quick installation, superior strength and longevity, as well as being fire-resistant. In this article, we will discuss precast concrete floor construction in detail, including its advantages and disadvantages. We will also provide answers to some common questions about precast concrete floor construction.

Advantages Of Precast Concrete Floor Construction

One of the main advantages of precast concrete floor construction is that it is quick and easy to install. Precast slabs can be easily transported to the site and quickly assembled into the required shape. The use of steel or reinforced concrete beams makes the assembly even faster and more efficient. As a result, precast concrete floors can be installed much faster than traditional methods such as pouring a concrete slab on-site.

Another advantage of precast concrete floor construction is its superior strength and longevity. The beams used in the construction are designed to withstand considerable force, making them ideal for use in high-traffic areas such as shopping malls, warehouses or even airport terminals. Furthermore, precast concrete floors are also fire-resistant, which makes them an ideal choice for buildings located in areas prone to fires.

Disadvantages Of Precast Concrete Floor Construction

One of the main disadvantages of precast concrete floor construction is that it is more expensive than traditional methods such as pouring a concrete slab on-site. The cost of transporting and assembling the beams and slabs can add up quickly, making it a costly option for some projects. Furthermore, depending on the size of the project, it may require additional labor costs in order to complete the installation process.

Another disadvantage of precast concrete floor construction is that it requires precise measurements when constructing the beams and slabs which can be difficult to achieve without having specialized knowledge and experience with these types of structures. As a result, mistakes during installation can cause delays in completing the project or even lead to costly repairs down the road.

FAQs About Precast Concrete Floor Construction

Q: What are the benefits of precast concrete floor construction?

A: The main benefits of precast concrete floor construction include quick installation, superior strength and longevity, as well as being fire-resistant. Precast floors are also less expensive than traditional methods such as pouring a concrete slab on-site and require less labor costs for installation.

Q: What are some potential drawbacks associated with precast concrete floor construction?

A: Some potential drawbacks associated with precast concrete floor construction include higher costs compared to traditional methods such as pouring a slab on-site as well as requiring precise measurements during installation which can be difficult to achieve without specialized knowledge or experience. Additionally, mistakes made during installation can result in costly repairs down the road.

Q: How long do precast floors typically last?

A: Precast floors typically last between 25 and 50 years depending on how they are maintained over time and how heavily they are used. Regular maintenance such as cleaning spills immediately And avoiding heavy impacts on the floor can help to prolong its life.

What are the advantages of precast concrete floor construction?

1. Speed: Precast concrete floor construction is much faster than traditional poured-in-place concrete floors since the precast panels are already manufactured off-site and ready to install. This also reduces labor costs, as the installation process is fairly straightforward.2. Strength: Precast concrete floors have superior strength and durability when compared to other flooring options. This makes them ideal for high-traffic areas where long-term stability is essential.

3. Versatility: Precast concrete floor systems can be customized to meet a variety of design requirements, from flat, level surfaces to complex shapes and curves. This versatility allows for creative freedom in floor design and eliminates the need for costly modifications down the line.

4. Cost Savings: Precast concrete floors offer significant cost savings over traditional poured-in-place concrete floors due to their speed of installation and reduced labor costs.

5. Fire Resistance: Precast concrete floors are highly resistant to fire, making them an ideal choice for commercial buildings or any space where fire safety is a priority.