Metallic Epoxy Flooring System

Related Images about Metallic Epoxy Flooring System

Epoxy Flooring Tallahassee Metallic Epoxy Floor Coatings

Poly urea pains ordinarily cost up to 4 times the volume of epoxy flooring as well as homeowners or business owners do not see any advantages of coming from the increased cost. Unfortunately this only comes in a single color, tan, although it may be utilized sometimes by itself or perhaps with other epoxy floorings.

Metallic Epoxy Flooring Metallic Epoxy Floor Coating Phoenix

Epoxy layer for floors are additionally really inexpensive compared to various other kinds of floor finishes like vinyl, wood, tile, and carpeting. In addition, it extends the lifetime of the concrete of yours and preserves it. Above each one of these rewards the most important is its economical cost. Hardwood floors are expensive and can be quickly damaged by drinking water.

Metallics – Lifetime Epoxy Floors

Epoxy covering additionally reduces the need to frequently clean the floors because epoxy repels and prevents spills and other contaminants from getting into the concrete. This expansion forms a solid barrier protection which lasts long enough for your fire being put out naturally or perhaps by a responding fire fighting staff. An epoxy floors beautifies some room, adding value to the house of yours, shop or restaurant.

Metallic Epoxy Flooring Epoxy Floor Coating Company

Metallic Epoxy Floor Coatings Epoxy Flooring Lansing

BRONZE RED & DARK BROWN & PEARL WHITE – epoxy floor incl. primer – EPODEX – United Kingdom

Metallic Epoxy Flooring, Metallic Epoxy Flooring Service in India

Liquid Marble – Epoxy Coat Texas – Houston Epoxy Flooring, Industrial Coatings

Platinum Floor Coating in Flooded Basement – V8 Floor Coating

Epoxy Flooring in White Lake, West Bloomfield, Clarkston, and More! – Armor Tough Coatings

Metallic Epoxy Flooring Service, For Industrial, Thickness: Max 100 Mm, Rs 45 /square feet ID

Commercial Metallic Epoxy Flooring Coating Solutions Black Bear

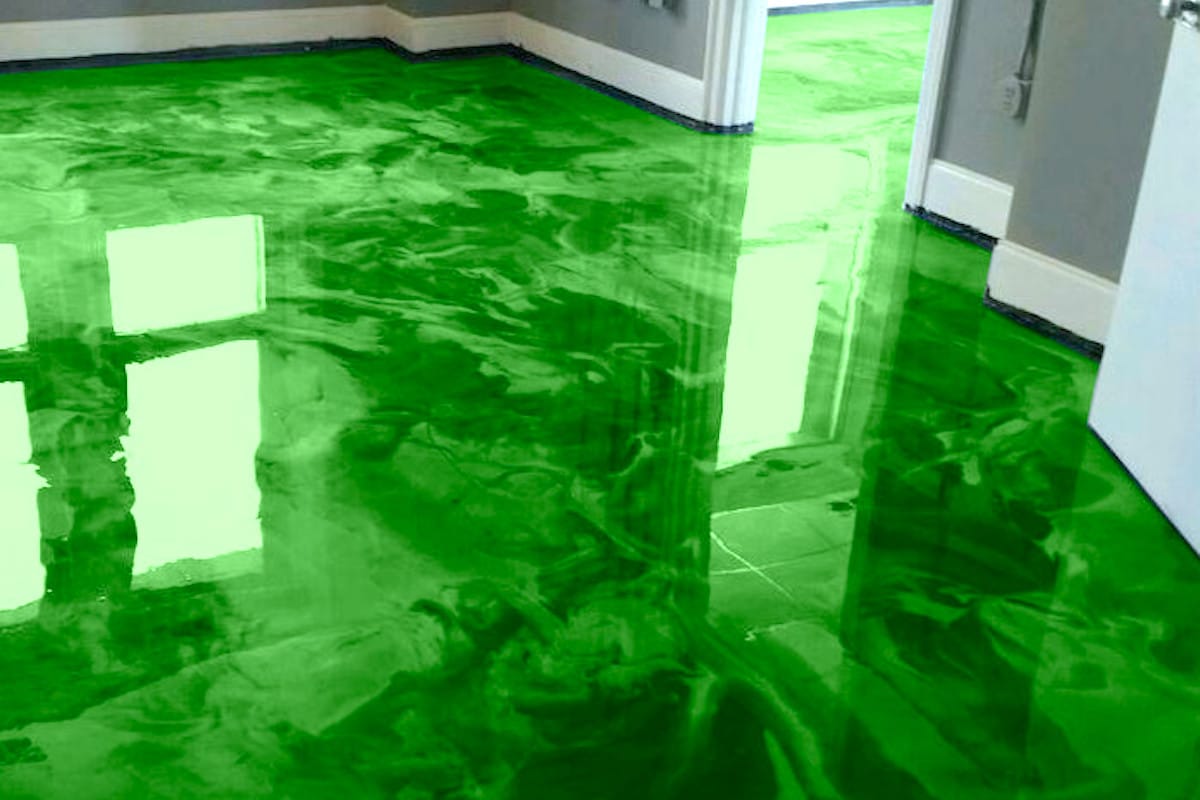

BAHIA GREEN & PEARL WHITE – epoxy floor incl. primer – EPODEX – United Kingdom

Platinum Seamless Bathroom Flooring – V8 Floor Coating

Related Posts:

- Epoxy Resin Floor Finish

- Commercial Grade Floor Epoxy

- Clear Self Leveling Floor Epoxy

- Epoxy Over Laminate Flooring

- Quikrete Floor Epoxy Reviews

- Outdoor Epoxy Resin Flooring

- Epoxy Floor Decals

- Epoxy Terrazzo Flooring Installation

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Flooring Baton Rouge

Metallic epoxy flooring system has become a popular choice for both residential and commercial spaces due to its unique and eye-catching appearance. This type of flooring combines epoxy resin with metallic pigments to create a stunning, glossy finish that resembles natural stone or marble. In addition to its aesthetic appeal, metallic epoxy flooring is also durable, easy to clean, and resistant to stains and chemicals.

Benefits of Metallic Epoxy Flooring System

One of the main advantages of metallic epoxy flooring is its versatility. It can be customized in terms of color, pattern, and texture to suit the design preferences of any space. Whether you want a sleek and modern look or a more rustic and textured finish, metallic epoxy flooring can be tailored to meet your needs.

Another benefit of metallic epoxy flooring is its durability. When properly installed and maintained, this type of flooring can last for many years without showing signs of wear and tear. It is also resistant to scratches, dents, and other types of damage, making it ideal for high-traffic areas such as kitchens, bathrooms, and commercial spaces.

In addition, metallic epoxy flooring is easy to clean and maintain. Unlike other types of flooring that require regular waxing or sealing, metallic epoxy flooring can be simply wiped clean with a damp mop or cloth. This makes it a practical choice for busy households or businesses that don’t have time for extensive maintenance routines.

Furthermore, metallic epoxy flooring is resistant to stains and chemicals, making it ideal for areas where spills are common. Whether you accidentally spill wine on your kitchen floor or drop chemicals in a garage or workshop, metallic epoxy flooring will not absorb the liquid or get damaged. This makes it a practical and cost-effective choice for spaces that require a durable and low-maintenance flooring solution.

Installation Process of Metallic Epoxy Flooring System

The installation process of metallic epoxy flooring involves several steps to ensure a smooth and flawless finish. First, the existing floor surface needs to be thoroughly cleaned and prepared to remove any dirt, grease, or debris. This may involve sanding or grinding the surface to create a smooth and level base for the epoxy resin.

Next, the metallic pigments are mixed with the epoxy resin according to the desired color scheme. The mixture is then poured onto the prepared floor surface and spread evenly using a trowel or roller. The pigments create unique patterns and designs as they flow and blend together on the floor.

Once the epoxy resin has cured and hardened, a topcoat sealer is applied to protect the surface from scratches, UV rays, and other types of damage. This sealer also enhances the shine and depth of the metallic pigments, creating a stunning visual effect that will impress guests or customers.

Finally, the floor is left to cure for several days before it can be used again. During this time, it’s important to avoid heavy foot traffic or placing heavy furniture on the newly installed metallic epoxy flooring to prevent damage.

Common Mistakes to Avoid with Metallic Epoxy Flooring System

1. Skipping proper surface preparation: One of the most common mistakes when installing metallic epoxy flooring is not properly preparing the existing floor surface. Failing to remove dirt, grease, or old coatings can result in adhesion issues and an uneven finish.

2. Using incorrect mixing ratios: Another common mistake is not following the manufacturer’s instructions when mixing the metallic pigments with the epoxy resin. Using incorrect ratios can affect the final color and pattern of the flooring.

3. Rushing the installation process: It’s Important to take your time during the installation process of metallic epoxy flooring to ensure a high-quality finish. Rushing the process can lead to mistakes, uneven application, and a less durable floor surface.

4. Not applying a topcoat sealer: Skipping the application of a topcoat sealer can leave the metallic epoxy flooring vulnerable to scratches, UV damage, and other types of wear and tear. It’s essential to protect the surface with a sealer to prolong its lifespan and maintain its appearance.

5. Overlooking maintenance and care instructions: Once the metallic epoxy flooring is installed, it’s important to follow proper maintenance and care instructions to keep it looking its best. Regular cleaning and avoiding harsh chemicals or abrasive cleaners will help preserve the finish and extend the life of the floor.

By avoiding these common mistakes and following the proper installation and maintenance procedures, you can enjoy a beautiful and durable metallic epoxy flooring system in your home or business for years to come. Overall, metallic epoxy flooring is a unique and visually stunning option for residential and commercial spaces. By taking the time to properly prepare the surface, mix the pigments correctly, apply a topcoat sealer, and follow maintenance guidelines, you can ensure a long-lasting and beautiful finish that will impress visitors and customers alike. Remember to work carefully and patiently during the installation process to achieve the best results possible with metallic epoxy flooring. In conclusion, metallic epoxy flooring is a popular choice for homeowners and business owners looking to add a touch of elegance and durability to their spaces. By avoiding common mistakes such as improper surface preparation, incorrect mixing ratios, rushing the installation process, skipping the topcoat sealer, and overlooking maintenance instructions, you can ensure that your metallic epoxy flooring looks its best and lasts for years to come. With proper care and attention to detail, your metallic epoxy flooring can continue to impress visitors and customers with its stunning visual effects and high-quality finish.