Metal Mesh For Concrete Floor

Related Images about Metal Mesh For Concrete Floor

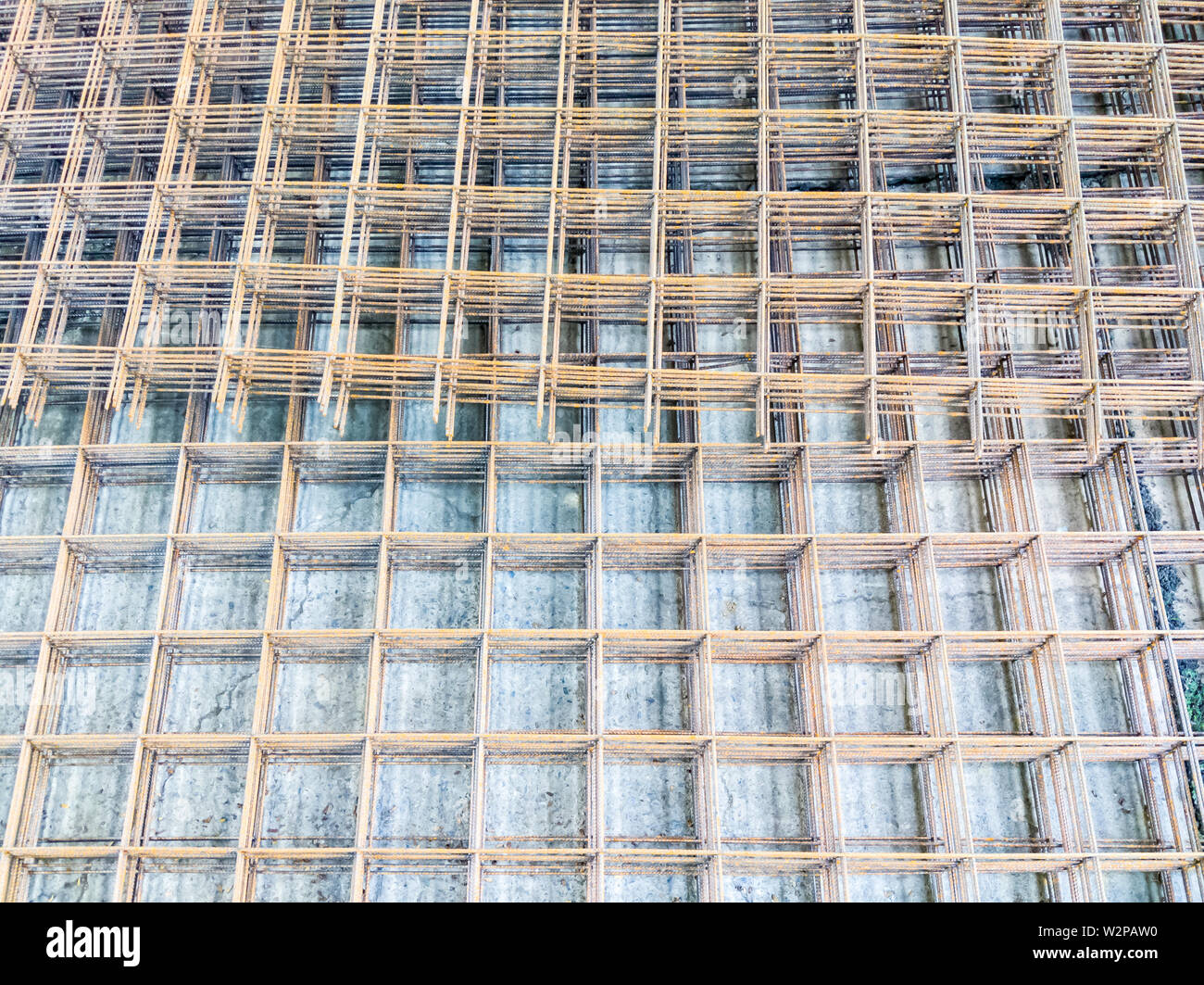

Ribbed Steel Concrete Mesh for Construction Reinforcement

Hard concrete floors has the possibility to intensify sounds, although that weakness can be rectified with no difficulty by the addition of some judiciously-placed rugs, mats or runners. In terminology that are straightforward , floors that are polished generate use of concrete polishing which is a mechanically ground material that is in that case polished to attain a particular appearance.

Best Concrete Wire Mesh Rebar And Reinforced Concrete Ontario

Developing with concrete countertops outdoors is likewise appealing because of their basic maintenance and great style flexibility. Concrete polishing is the finish of choice for the majority of owners of new and the latest concrete floors. Polished concrete is seamless, leaving no place for dust mites to gather and expose the bacteria that may be trapped between floorboards and tiles.

Galvanized Steel Wire Mesh Panels And Concrete Reinforcing Weld Mesh Panels – Buy Steel Wire

more and More homeowners as well as designers are creating warehouses and basements with concrete because of the look, the natural beauty, the simplicity in attention and the warmth it brings to an area. The process is simple to use with state-of-the-art technology. If you walk into a place that has polished concrete flooring, you will realize immediately that the dojo is somewhat similar to marble.

Steel Wire Mesh For Concrete Floor In Construction Site Stock Photo – Image of mesh, abstract

Steel Wire Mesh Concrete Floor Stock Photos & Steel Wire Mesh Concrete Floor Stock Images – Alamy

How to Use Steel Fibers in Concrete Concrete Construction Magazine

Best Steel Reinforcing Mesh With Freshly Poured Concrete Slab Stock Photos, Pictures & Royalty

old rough wooden floor boards background www.myfreetextures.com Free Textures, Photos

Steel Wire Mesh Concrete Floor High Resolution Stock Photography and Images – Alamy

Concrete reinforcing mesh roll reinforced concrete slab(factory), View concrete reinforcing mesh

Concrete Mini Mix Concrete Suppliers Melbourne Westernport Sand & Soil

How To Install A Mesh Subfloor (Tiling Preparation) – YouTube

Thickness Than 6mm Heavy Duty Steel Grating Galvanized Bar Grating for sale – Heavy Duty Steel

another woven bamboo wooden floor background image www.myfreetextures.com Free Textures

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction

Metal mesh for concrete flooring is an excellent option for long-term durability and strength. It provides a superior foundation for a wide range of commercial and industrial applications, such as warehouses, factories, and workshops. Metal mesh is designed to form a strong and secure surface that is highly resistant to impacts, vibration, and weather. It also helps to protect against fire hazards, providing extra safety from potential hazards. In addition, metal mesh offers the added benefit of being less expensive than traditional concrete flooring solutions. This article will provide an overview of metal mesh for concrete flooring systems, explaining the benefits and features of this type of system.

What is Metal Mesh For Concrete Floor?

Metal mesh for concrete flooring systems are designed to provide a durable foundation for various commercial and industrial applications. It is made up of different types of meshes that are welded together in order to form a strong and secure surface. This type of flooring is highly resistant to impact, vibration, and weather, making it an ideal choice for areas prone to heavy foot traffic or harsh environmental conditions. The metal meshes used in these systems are also designed to be fire-resistant, providing extra protection from potential hazards. Additionally, since metal mesh is less expensive than traditional concrete flooring solutions, it can help reduce overall costs associated with construction projects.

Advantages of Metal Mesh For Concrete Floor

Metal mesh for concrete flooring systems offer numerous advantages over traditional methods. One of the most notable benefits is that they provide a durable foundation that can withstand heavy foot traffic and harsh environmental conditions. Additionally, metal mesh is highly resistant to impacts and vibrations, making it suitable for use in a variety of industrial settings. Furthermore, metal mesh is also fire-resistant, providing extra safety from potential hazards. Lastly, since this type of system is less expensive than traditional concrete flooring solutions, it can help reduce overall costs associated with construction projects.

Installation Process

Installing metal mesh for concrete flooring systems requires careful preparation and planning in order to ensure a successful outcome. The first step involves measuring the area where the system will be installed in order to determine the amount of material needed. Once the measurements have been taken, the next step involves cutting the metal meshes according to the required size using specialized tools such as shears or saws. After the pieces have been cut to size, they should be welded together using high-grade welding equipment in order to form a strong and secure surface that can withstand heavy foot traffic and harsh environmental conditions. Finally, once the welding process has been completed, the metal mesh should be applied directly onto the concrete surface using an adhesive or cement mixture in order to ensure a secure bond between the two materials.

Maintenance Guidelines

In order to maintain the integrity of metal mesh for concrete flooring systems, it is important to follow certain maintenance guidelines on a regular basis. First and foremost, it is essential that any debris or dirt particles be removed regularly using a broom or vacuum cleaner in order to prevent any damage or deterioration of the material over time. Additionally, any spills should be wiped up immediately in order to avoid staining or discoloration of the surface. Finally, it is important that any repairs or modifications be carried out by experienced professionals in order to ensure optimal performance throughout its lifespan.

FAQs About Metal Mesh for Concrete Flooring Systems

Q: What is the lifespan of metal mesh for concrete flooring systems?

A: Metal mesh for concrete flooring systems can last for many years, depending on the quality of the materials used and the amount of maintenance that is done on a regular basis. In general, these systems are designed to be highly durable and can withstand heavy foot traffic and harsh environmental conditions.

Q: How much does it cost to install metal mesh for concrete flooring systems?

A: The cost of installing these systems varies depending on the size of the area being covered, the type of material used, and the labor costs associated with the project. Generally speaking, metal mesh for concrete flooring systems are more affordable than traditional concrete flooring solutions, making them an ideal choice for those looking to save money on their construction projects.