Lightweight Concrete Flooring Systems

Related Images about Lightweight Concrete Flooring Systems

INTEGRA Lightweight Concrete Flooring System by Resene Construction Systems – EBOSS

Sealants, for example a polymer flooring seal, offer a lot of positives to interior and exterior floor surfaces and therefore are an excellent addition to a concrete floors maintenance program. Caring for the decorative concrete floors of yours is not much different than the standard upkeep you perform in any aspect of the home of yours.

INTEGRA Lightweight Concrete Flooring System by Resene Construction Systems – EBOSS

In addition to a mirror like shine, concrete flooring might be spruced up with embedded patterns, lines, images, grids and other designs. They impart a luxurious richness that can’t be attained by another flooring. With more properties being built in a contemporary style, concrete polishing floors is growing in leaps as well as bounds. Coarse pads file down the very best surface area of the concrete.

Bank Headquarter Interior Concrete Wall Design Project in Istanbul Turkey Completed by CRETOX

Staining concrete flooring is something that you can easily do yourself or even spend a professional to do in the event that you’d like an even more complex decorative concrete strategy. The benefits of the polished concrete floors are very numerous and for anybody aiming to have excellent flooring, it is prudent not to appear any further than the polished flooring surfaces.

commercial concrete flooring – YouTube

Polished Concrete Pictures

Better floor performance starts with a solid subfloor system – Page 3 of 5 – Construction Canada

Concrete Floor Preparation Prior to Receiving Flooring – ProInstaller Magazine

Why Polished Concrete is the must have flooring system

Microscreed – Floored Genius Microscreed Floors Alternative to Polished Concrete Floors

Basement Questions: Basement Flooring Systems

Raised Flooring Systems for 911 Call Centers Pro Access

Stone Deck Tiles

Suspended Concrete Flooring – Speedfloor

STRUCTURE magazine Is Lightweight Concrete All Wet?

Related Posts:

- Polished Concrete Floors In Apartments

- Basement Concrete Floor Paint Ideas

- Sanding Concrete Floors For Stain

- How To Seal Concrete Floor Before Carpeting

- Concrete Floor Tile Preparation

- Cold Concrete Floor Solutions

- Stained Concrete Floor Care

- Polished Concrete Floor Bedroom

- Bare Concrete Floor Ideas

- Covering A Concrete Floor

When it comes to flooring options, lightweight concrete is gaining popularity due to its unique properties and benefits. Lightweight concrete is a type of concrete that contains lightweight aggregates such as pumice, expanded clay or shale, perlite, or vermiculite. These aggregates reduce the overall weight of the concrete while still maintaining its strength and durability. Lightweight concrete flooring systems are being used in various residential, commercial, and industrial applications due to their versatility and performance.

Benefits of Lightweight Concrete Flooring Systems

One of the main benefits of lightweight concrete flooring systems is their reduced weight compared to traditional concrete. This makes them ideal for upper-level floors where weight restrictions may be a concern. Additionally, lightweight concrete has excellent thermal properties, making it an energy-efficient choice for buildings. Its low thermal conductivity helps regulate indoor temperatures, reducing heating and cooling costs.

Another advantage of lightweight concrete flooring systems is their ease of installation. Due to their lighter weight, they are easier to transport and handle on-site. This can result in shorter construction times and lower labor costs. Lightweight concrete floors also provide excellent sound insulation properties, making them a popular choice for multi-family housing units or commercial buildings where noise reduction is important.

In terms of design flexibility, lightweight concrete flooring systems offer a wide range of finishes and colors to suit any aesthetic preference. They can be polished, stained, or textured to achieve different looks and styles. Additionally, lightweight concrete can be poured in place or precast off-site for added convenience and customization options.

Maintenance of lightweight concrete flooring systems is relatively easy compared to other types of flooring materials. Regular cleaning with a mild detergent and water is usually all that is needed to keep the floors looking like new. Sealing the surface periodically can help protect the concrete from stains and wear over time.

Common Mistakes to Avoid

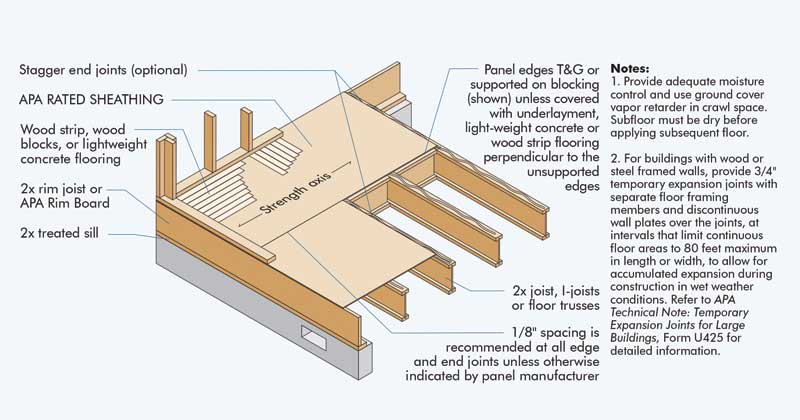

One common mistake when installing lightweight concrete flooring systems is not properly preparing the subfloor before installation. It is important to ensure that the subfloor is clean, level, and free of any debris or contaminants that could affect the adhesion of the lightweight concrete. Failure to do so could result in uneven floors or delamination over time.

Another mistake to avoid is using the wrong type of lightweight aggregate in the concrete mix. Each type of lightweight aggregate has different properties that can affect the overall performance of the concrete. It is essential to consult with a professional to determine which type of aggregate is best suited for your specific project requirements.

Overworking the lightweight concrete during installation can also lead to issues such as cracking or surface imperfections. It’s important to follow proper mixing and pouring techniques to ensure a smooth and durable finish. Additionally, not allowing enough time for the concrete to cure before placing heavy furniture or equipment on it can cause premature damage.

Neglecting regular maintenance and sealing of lightweight concrete floors is another common mistake that can lead to deterioration over time. Proper care and maintenance will help preserve the appearance and performance of the floors for years to come.

FAQs about Lightweight Concrete Flooring Systems

1. Is lightweight concrete as durable as traditional concrete?

Yes, despite its reduced weight, lightweight concrete maintains its strength and durability due to the presence of high-quality aggregates.

2. Can lightweight concrete flooring systems be installed in outdoor spaces?

Yes, lightweight concrete flooring systems can be used outdoors as well, but it’s essential to choose a suitable finish that can withstand exposure to weather elements.

3. How long does it take for lightweight concrete floors to cure?

The curing time for lightweight concrete floors can vary depending on Factors such as the specific mix used, temperature, and humidity levels. In general, lightweight concrete typically cures within 7-14 days, but it is advisable to wait at least 28 days before subjecting the floors to heavy use or furniture placement.

4. Can lightweight concrete flooring systems be customized in terms of color and texture?

Yes, lightweight concrete flooring systems offer a wide range of customization options in terms of color, texture, and finish. Staining, polishing, and texturing techniques can be used to achieve various looks and styles to suit your design preferences.

5. Are lightweight concrete floors suitable for high-traffic areas?

Yes, lightweight concrete floors are durable and can withstand heavy foot traffic when properly installed and maintained. They are a popular choice for commercial spaces such as retail stores, restaurants, and offices due to their strength and longevity.

6. How does the cost of lightweight concrete flooring compare to traditional flooring materials?

The cost of lightweight concrete flooring systems can vary depending on factors such as the type of finish chosen, installation method, and project size. In general, lightweight concrete is comparable in cost to traditional flooring materials like hardwood or tile but offers additional benefits such as durability and ease of maintenance.

Overall, lightweight concrete flooring systems are a versatile and durable option for both residential and commercial spaces. By avoiding common mistakes during installation and maintenance and consulting with professionals for guidance on material selection and customization options, you can enjoy beautiful and long-lasting lightweight concrete floors for years to come.