Isolation Membranes For Tile Floors

Related Images about Isolation Membranes For Tile Floors

Technical Focus: Cracks kill tile floors 2017-08-01 Tile Magazine

You'll find a whole lot of tile floor cleansers on the market at the second and this could intimidate a great deal of people today. They're also a lot simpler to cleanse in comparison to various other flooring types. These're produced by using pressure that is high to compact dust and have a hard and durable resulting product. Make sure you've all the materials and tools before beginning the job.

How to Prevent Tile Cracks Professional Builder

Tiles are easy to clean to remove several damaging allergens. Together with the creativity and creativity, you are able to create a floors design that's unique to your home and provide the rooms of your house a great personality, your personality. The tile flooring would be a suitable alternative for your breath room. The next task is wiping the linoleum flooring until it appears to be clean.

3mm Floor Underlayment Membrane Used For Ceremic Floor Tile/waterproof/support/uncoupling – Buy

Tiles are a lot easier to set up though the protection offered to concrete can easily be done by painting also. Creating your own tile pattern and adding a complement floor tile allows you to decorate the floor in the own way of yours. They're durable and long lasting – and this is why ceramic tile flooring has been used in bathrooms and kitchens with good results.

Tiling Floor Using an Underlayment Membrane – YouTube

Anti Fracture Membrane For Tile Floors – Carpet Vidalondon

How to Tile a Floor Using an Underlayment Membrane Today’s Homeowner

Waterproof Breathable Tiles Underlayment Membrane – Buy Tiles Underlayment Membrane,Breathable

Vapor Barrier For Laminate Flooring / How To Install The Moisture Barrier Over Concrete Subfloor

Tile Underlayment Membrane Today’s Homeowner

Installing a PermaStone Modular Vinyl Tile Floor

Waterproofing & Crack Isolation Membranes Custom Building Products

Auto forward to correct web page at InspectAPedia.com

Waterproofing Membranes by Laticrete

Green Skin Flooring Underlayment Membrane- StoneTooling.com

Related Posts:

- Commercial Porcelain Tile Flooring

- Ideas Covering Tile Floors

- Steam Mop For Hardwood And Tile Floors

- Shaw Vinyl Tile Flooring

- Herringbone Wood Look Tile Floor

- Chair Casters For Tile Floors

- Bona Mops For Tile Floors

- How Clean Porcelain Tile Floor

- How To Install Natural Stone Tile Flooring

- How Much To Install Tile Floor Per Square Foot

Introduction to Isolation Membranes For Tile Floors

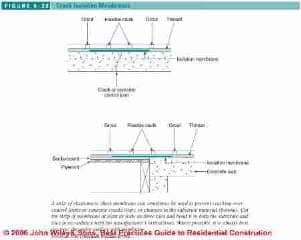

Isolation membranes are a type of material that can be used when installing tile floors. These membranes are designed to separate the substrate from the tile and create an impervious barrier between the two materials. This prevents moisture from getting into the substrate, allowing the tile to remain dry and free of cracking or warping. Isolation membranes also reduce noise transmission and add a layer of protection to the underlying flooring material. In this article, we will discuss what isolation membranes for tile floors are, the types available, their benefits, installation tips, and more.

What Are Isolation Membranes For Tile Floors?

Isolation membranes are thin sheets of material that are used as a protective barrier between the substrate and tile in flooring installations. The membrane is laid down first before the tile is applied to create a waterproof barrier that prevents moisture from entering the substrate. This helps to protect the tile from warping, cracking, and other damage due to water exposure. Isolation membranes also reduce noise and provide additional protection for underlying flooring materials from abrasion and wear.

Types of Isolation Membranes For Tile Floors

There are several different types of isolation membranes available for use with tile flooring installations. The most common types include self-leveling cementitious membranes, liquid-applied membranes, sheet-applied membranes, and roll-on membranes. Each type has its own advantages and disadvantages which should be considered when selecting a membrane for your project.

Self-leveling cementitious membranes are one of the most popular types of isolation membrane for tile floors because they provide an even surface for tiling. These membranes are easy to install and can be applied quickly with minimal preparation needed on the substrate. They also provide strong protection against water penetration while allowing some movement within the tiles if needed.

Liquid-applied membranes are another popular option for tile flooring installations. These products can be sprayed or brushed onto the substrate to create an impermeable barrier that provides excellent protection against water penetration. Liquid-applied membranes offer superior coverage compared to other types of isolation membrane but require more time and effort for proper installation.

Sheet-applied membranes are pre-manufactured sheets that can be cut to size and installed over the substrate before tiling begins. These products offer good protection against water penetration but require more time for installation compared to other types of membrane. Sheet-applied membranes also need to be sealed at all edges in order to ensure proper performance.

Roll-on membranes are made using a special adhesive that can be rolled onto the substrate before tiling begins. These products provide good coverage but require more time for installation compared to other types of isolation membrane. Roll-on membranes also need to be sealed along all edges in order to ensure proper performance.

Benefits Of Isolation Membranes For Tile Floors

Isolation membranes offer several benefits when used in a tile flooring installation. By creating a waterproof barrier between the substrate and tile, these products help protect against water damage which can cause tiles to warp or crack over time. Isolation membranes also reduce noise transmission by acting as an insulator between the two materials which helps keep sound levels lower in tiled areas . Additionally, these products provide additional protection against abrasion and wear which makes them ideal for use in high-traffic areas.

What type of material is used to make isolation membranes for tile floors?

Isolation membranes for tile floors are typically made of polyethylene foam or a rubberized asphalt membrane. Polyethylene foam is lightweight and flexible, making it well-suited for use in areas with limited space. It is also resistant to moisture and can provide a strong barrier against water penetration. Rubberized asphalt membranes are thicker and heavier than polyethylene foam and offer superior protection against water damage. They are more difficult to install but provide increased durability and can be used in areas subject to heavy foot traffic.What are the advantages of using isolation membranes for tile floors?

1. Isolation membranes can provide a barrier between the subfloor and the tile, preventing movement of the tile and cracking of the grout lines.2. Isolation membranes can reduce sound transmission between floors.

3. They can help to protect the subfloor from moisture damage, which can cause tiles to loosen or become mouldy.

4. Isolation membranes can provide an extra layer of insulation, making floors more comfortable to walk on in cold climates.

5. They can be used as a crack isolation membrane to prevent cracks in tiles from propagating through the tile layers, allowing for a longer lasting flooring system.