Installing Solid Wood Flooring On Concrete

Related Images about Installing Solid Wood Flooring On Concrete

Installing Wood Flooring Over Concrete – Summary: The Family Handyman Diy wood floors, Diy

When we do this you need to have the ability to tell from the construction what type of floor it is. Laminate flooring is favoured by those hoping to cover big areas in a durable cost-effective material. The vast majority of the hardwood floors used these days is built wood, comprised of several levels of substrate plywood having a finishing veneer (thin) layer of wood pre selected in numerous types & colors complimenting the completed product.

Elastilon® Revolutionizes Hardwood Floor Installation

The choices of wood species is also amazing, for this reason it could be a hard choice, although it is going to be a decision the homeowner will be thrilled to enjoy for many decades to come. Growing your wood floor lacquered is going to protect it and allow it to be keep going longer although some individuals choose to have an even more natural look to their wood floors and as such choose not to lacquer the floors of theirs.

Installing Wood Flooring Over Concrete (DIY)

Natural stone or tile flooring was reserved only for the financially elite, big companies, or government buildings because of cost. The volume of sustainable forest management causes it to be simple for us to harvest wood without having really serious influence on the environment of ours. Engineered wood flooring can be purchased in various styles. It is not hard when you know how. There are no anti-scratch warranties in the wood floors business.

How to Install Hardwood Flooring on Concrete eHow

Installing Wood Flooring Over Concrete

Installing Wood Flooring Over Concrete – ReclaimedFloors.net

Installing A Hardwood Floor Over Concrete Slab Floor Roma

How To Install Hardwood Floors On Cement TcWorks.Org

Installing Wood Laminate Flooring Over Concrete – Carpet Vidalondon

How to Fit an Engineered Wood Floor Homebuilding & Renovating

Can I Install Wood Flooring Over Concrete?

Your Sub-Floor and You: What Lies Beneath – Reno-Tahoe-Nevada

Engineered Hardwood Flooring Carlisle Wide Plank Floors

itavi.com

Related Posts:

- Wood Floor Modern Kitchen

- Wood Floor Garage Plans

- Real Wood Flooring In Kitchen

- Wood Floor Cork Underlayment

- Streak Free Wood Floor Cleaning

- Solid Wood Flooring White Washed Oak

- Engineered Wood Flooring Durability

- Wood Flooring Types Hardness

- Engineered Wood Flooring Formaldehyde Emission

- Wood Floors For Beach House

Installing Solid Wood Flooring On Concrete: A Step-By-Step Guide

Wood flooring is a timeless, classic choice for any home. Whether you’re looking to add a touch of sophistication to your living room or create a cozy, rustic atmosphere in your bedroom, solid wood flooring will do the trick.

One of the most common questions homeowners ask when installing wood flooring is: can it be installed on concrete? The answer is yes, it is possible to install solid wood flooring on concrete. However, there are some steps that must be taken to ensure the job is done properly and safely. In this article, we’ll provide a step-by-step guide to installing solid wood flooring on concrete.

Prepping the Concrete Subfloor

The first step when installing solid wood flooring on concrete is to make sure the concrete subfloor is prepped correctly. The subfloor should be level, clean, dry and free of any debris or dirt. If the subfloor isn’t level, you’ll need to use a self-leveling compound to fill in any dips or depressions in the concrete.

Next, you’ll need to check for moisture levels before you begin laying down the wood flooring boards. Use a moisture meter or calcium chloride test kit to determine if there is too much moisture present. If so, you may need to use a vapor barrier before moving forward with installation.

Finally, you’ll want to fill in any cracks or holes in the subfloor with an epoxy filler. This will help create a smooth surface for your wood flooring boards and prevent them from shifting over time.

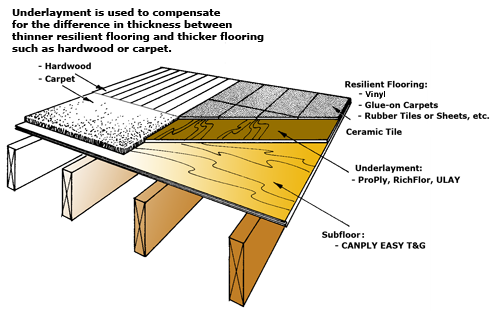

Laying Down Underlayment

Once the subfloor has been prepped correctly, it’s time to lay down underlayment. Underlayment helps protect the wood floors from moisture and also acts as an extra layer of insulation against cold temperatures. When selecting an underlayment material, choose one that is designed specifically for use with hardwood floors – this will help ensure your floors last for many years to come.

Installing The Floor Boards

Once you have your underlayment in place, it’s time to start installing the solid wood floor boards themselves. Start by laying out all of your boards and making sure they fit together without any gaps or overlapping edges. Once you have the layout figured out, attach each board with nails or glue depending on what type of installation method you are using (glue-down vs nail-down). Make sure each board is secure before moving onto the next one; if it feels wobbly at all take steps to make sure it won’t move before continuing with installation.

Finishing Touches

Once all of your boards are installed, you can finish up with some finishing touches like baseboard trim and quarter round moldings if desired. You may also want to apply a sealant or stain for added protection against water damage or fading due to sun exposure.

FAQs About Installing Solid Wood Flooring On Concrete

Q: How long does it take for solid wood flooring on concrete to dry?

A: It typically takes between 24 And 48 hours for solid wood flooring on concrete to dry completely. It is important to leave the floor undisturbed during this time to ensure a proper cure.

Q: What kind of tools do I need to install solid wood flooring on concrete?

A: You will need a hammer, nails, level, tape measure and a saw for cutting the boards to size. You may also want to invest in an air compressor and nail gun for quicker installation.

What tools are needed for installing solid wood flooring on concrete?

Tools needed for installing solid wood flooring on concrete include:1. Tape measure

2. Chalk line

3. Nail gun

4. Hammer

5. Pry bar

6. Circular saw

7. Drill and bits

8. Level

9. Underlayment

10. Tapping block and mallet

11. Adhesive

12. Spacers

13. Finishing materials (trim, quarter round, etc.)