Industrial Epoxy Floor Patch

Related Images about Industrial Epoxy Floor Patch

Epoxy Floor Coatings – Suppliers & Manufacturers in India

Epoxy floors come in all of kinds of varieties & styles. On the flip side, if you have a brand new slab, wait for no less than a month for the floors to be thoroughly dry before epoxy program. Sometimes the epoxy paints can be offered desired textures as well. There are a whole lot of rewards in employing epoxy as being a floor coating. The price of an epoxy floors is comparable to that of other flooring sorts.

Epoxy Patch Repair Epoxy Floor Coatings Part #2 – YouTube

Flooring is a terrific decision to make for the house, commercial business, or perhaps industrial sector. If you do not, it's wise to have an expert do it. They have colored chips or maybe flakes inlaid within the flooring surfaces and these lend a very decorative and aesthetic feel to the floor. The best surface to lay epoxy flooring is actually concrete, although you are able to install epoxy flooring over surfaces which include wood as well as steel too.

Epoxy Antistatic Flooring, एपोक्सी सेल्फ लेवलिंग एंटी स्टेटिक फ्लोरिंग – Supreme Polytec Private

This forms a rigid plastic material which is good, reluctant to degradation, and that bonds quite well to the substrate of its. So, before you apply epoxy on the flooring of yours, you need to assess first the state of your concrete if it makes moisture or perhaps not. Of these 3, hundred % solids epoxy is the perfect option as it performs probably the best.

Anti static Epoxy Flooring Services, For Indoor, Chemical Resistant, Rs 48 /square feet ID

Epoxy Patching Compound Tampa FL Expert Concrete Flooring Company

Devcon Floor Patch, Epoxy, Gray, 3-Part, 10-lb. Kit 13110 Zoro.com

Epoxy/Urethane Mortars National Polymers Inc.

Concrete Joint Filler by Protective Industrial Polymers

Industrial Safety Coatings – Epoxy Floor Coating Contractors

Garage Floor Coating Process Epoxy Floors Greenville, WI

Epoxy Flooring Installation Process Garage Floor Coating Install

Anti Static Epoxy Floor Coating Epoxy Floor

Water based epoxy primer: Paint, Steel, Concrete – Epoxy Pro

Vinyl Chip Epoxy :: Photos Decorative Concrete of Virginia (VA)

Related Posts:

- How To Epoxy Floor Paint

- Black Metallic Epoxy Floor

- Spiked Rollers For Epoxy Flooring

- Epoxy Flooring Matte Finish

- Epoxy Floor Painting Ideas

- Rustoleum Epoxy Professional Floor Coating

- Water Based Epoxy Floor Paint

- What Is Metallic Epoxy Flooring

- How To Epoxy Paint A Concrete Floor

- How To Apply Epoxy Floor Paint To Basement

Industrial Epoxy Floor Patch: A Comprehensive Guide to Repairing and Protecting Your Floors

Introduction:

Industrial floors are subjected to heavy traffic, impact from machinery, and exposure to chemicals on a daily basis. Over time, this can lead to cracks, chips, and other damages that not only compromise the aesthetics of the floor but also pose safety risks. To address these issues effectively, industrial epoxy floor patching is an ideal solution. In this article, we will delve into the details of industrial epoxy floor patching, its benefits, application process, frequently asked questions, and more.

I. Understanding Industrial Epoxy Floor Patch:

Industrial epoxy floor patch is a specialized blend of epoxy resin and other additives designed to repair and protect damaged concrete floors. It provides a durable, seamless finish that withstands heavy loads, chemical spills, and abrasion. This versatile material can be applied in various thicknesses depending on the severity of the damage and desired level of protection.

FAQ 1: What are the advantages of using industrial epoxy floor patch?

Answer:

– Enhanced Durability: Industrial epoxy floor patch provides exceptional durability, extending the lifespan of your floors.

– Chemical Resistance: The epoxy material is highly resistant to a wide range of chemicals commonly found in industrial environments.

– Seamless Finish: Once applied, the epoxy floor patch creates a seamless surface that prevents dirt buildup and makes cleaning easier.

– Impact Resistance: The high-strength properties of epoxy make it resistant to impacts from heavy machinery or falling objects.

– Aesthetics: With a variety of colors and finishes available, industrial epoxy floor patch can enhance the overall look of your facility.

II. Application Process:

To ensure a successful application of industrial epoxy floor patch, it is essential to follow the proper steps. Here is a detailed breakdown of the application process:

1. Surface Preparation:

The key to a long-lasting epoxy floor patch is thorough surface preparation. This involves cleaning the damaged area, removing loose debris, and repairing any underlying structural issues if necessary. The surface should be clean, dry, and free of grease or oil before proceeding to the next step.

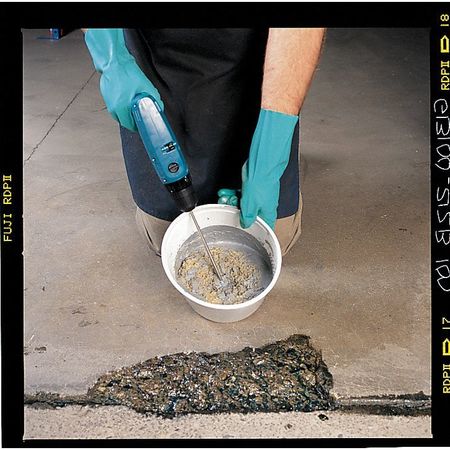

2. Mixing the Epoxy Patch:

Follow the manufacturer’s instructions to mix the epoxy floor patch compound accurately. It is crucial to achieve a uniform consistency to ensure optimal performance.

3. Applying the Patch:

Using a trowel or a putty knife, apply the epoxy patch mixture to the damaged area. Make sure to spread it evenly and fill any cracks or pits completely. For larger repairs, multiple layers may be required, allowing each layer to cure before applying the next.

4. Smoothing and Leveling:

Once applied, use a trowel or a squeegee to smooth and level the epoxy floor patch. This step ensures a seamless finish and removes any excess material.

5. Curing Time:

Allow sufficient time for the epoxy patch to cure according to the manufacturer’s guidelines. During this period, it is essential to restrict foot and vehicle traffic on the repaired area.

FAQ 2: Can industrial epoxy floor patch be used on all types of floors?

Answer:

Industrial epoxy floor patch is primarily designed for concrete floors, but it can also be used on other types of surfaces such as wood or metal with proper surface preparation. However, it is crucial to consult with a professional or refer to the product specifications for compatibility and suitability.

III. Choosing the Right Epoxy Floor Patch:

Not all epoxy floor patches are created equal, and selecting the right One for your specific needs is crucial. Here are some factors to consider when choosing an epoxy floor patch:

1. Purpose: Determine the purpose of the floor patch, whether it is for repairing cracks, filling holes, or leveling uneven surfaces. Different epoxy patches have varying properties and are designed for specific applications.

2. Durability: Consider the level of durability required for your facility. If heavy machinery or high traffic is present, opt for a high-strength epoxy patch that can withstand impacts and abrasions.

3. Chemical Resistance: Assess the type of chemicals present in your industrial environment and select an epoxy patch that has excellent resistance to those chemicals. This will ensure long-lasting performance and prevent damage from chemical spills or exposure.

4. Compatibility: Ensure that the epoxy floor patch is compatible with the existing flooring material. Some materials may require specific primers or surface preparation techniques for proper adhesion.

5. Aesthetics: If aesthetics are important to you, choose an epoxy patch that offers a variety of colors and finishes to enhance the overall look of your facility.

6. Ease of Application: Consider the ease of application of the epoxy floor patch. Some products may require specialized equipment or professional installation, while others can be applied by anyone with basic DIY skills.

7. Cost: Lastly, consider your budget and compare prices of different epoxy floor patches. However, it is important to prioritize quality and performance over cost to ensure a long-lasting and durable solution.

By considering these factors and consulting with professionals if needed, you can choose the right epoxy floor patch that meets your specific requirements and provides optimal performance for your industrial facility.