Garage Floor Resurfacing Products

Related Images about Garage Floor Resurfacing Products

Garage Floor Resurfacing: Fix a Pitted Garage Floor Weekend projects, Garage floor resurfacing

These paints come in many different colors and styles and are created for outdoor use, so they're very durable. These mats are sold in rolls. The material functions by bonding to the cement of yours and is often made up of epoxy item. You'll find 3 strategies to addressing the floors surface: epoxy paint, garage floor mats as well as garage floor flooring.

Garage Floor Resurfacing – YouTube

Probably the fastest way to improve your garage is by the use of floor mats created to cover either part or all of the floor region. I've seen that paint type on garage flooring before and it looks extremely good. It doesn't take considerably more than a week's period to complete the task. At times this brings about an issue, at times it does not.

Garage Floor Resurfacing: Fix a Pitted Garage Floor Family Handyman

The more heavy duty professional grade mats normally cost more than light duty ones Along with the diverse types, patterns, in addition to duty ratings, you will be ready to select a roll through garage mat that fits the requirements of yours. Improving the appearance of your garage, or perhaps fixing those issue areas is a great time to utilize storage area floor coatings.

Garage Floor Resurfacing: Fix a Pitted Garage Floor The Family Handyman

Resurfacing and old garage floor- tips appreciated : HomeImprovement

Onfloor OF9S-L Single Disc Concrete Grinder Sale and Review

Garage Floor Resurfacing – How To Completely Resurface Your Garage Floor

Garage Floor Resurfacing – Amazing Garage Floors

Garage Floor Resurfacing: Fix a Pitted Garage Floor Family Handyman The Family Handyman

Repox-Mix Crack & Spall Industrial Concrete Repair KwikBond

How to Apply Epoxy Coating to a Garage Floor

/7184880388_7a10367e16_k-587ae00d5f9b584db399e346.jpg)

Concrete Slab Crack Repair Instructional Video – YouTube

Ohio Concrete Resurfacing: Concrete Sealing, Garage Floors

Easy to use concrete microtopping for beautiful cement floors

Related Posts:

- Valspar Garage Floor

- Self Levelling Garage Floor Paint

- Valspar Epoxy Garage Floor Paint

- Garage Floor With Flakes

- Garage Floor Sealer Vs Epoxy

- Bondall Garage Floor Paint Review

- How To Polish Concrete Garage Floor

- Garage Floor Paint Do It Yourself

- Drymate Garage Floor Mat Review

- Modular Interlocking Garage Floor Tiles

Garage Floor Resurfacing Products: Enhancing the Durability and Aesthetics of Your Garage

Introduction:

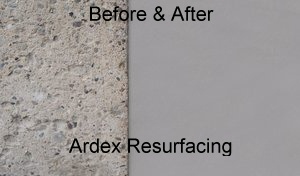

Your garage floor is subjected to constant wear and tear, from heavy vehicles to spills and stains. Over time, these factors can lead to cracks, uneven surfaces, and a worn-out appearance. However, with the advent of garage floor resurfacing products, you no longer have to settle for a lackluster garage floor. These innovative solutions offer a range of benefits, from improving durability to enhancing aesthetics. In this article, we will delve into the world of garage floor resurfacing products, exploring their types, features, and frequently asked questions to help you make an informed decision.

I. Understanding Garage Floor Resurfacing Products:

Garage floor resurfacing products are specially designed coatings or overlays that provide a fresh layer to your existing concrete floor. They are formulated to withstand heavy traffic, resist stains, and enhance the overall appearance of your garage. Let’s explore some popular options in greater detail:

1. Epoxy Coatings:

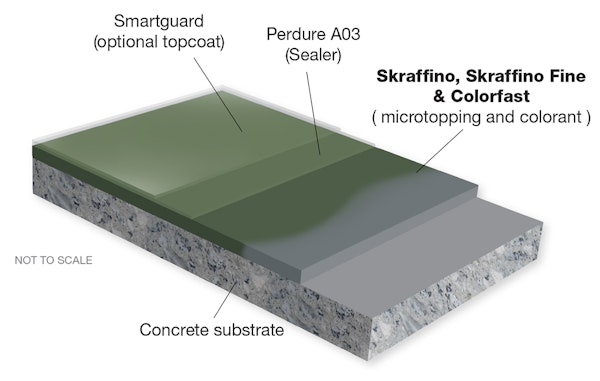

Epoxy coatings are one of the most popular choices for garage floor resurfacing. They consist of a two-part system comprising epoxy resin and a hardener. When mixed together, they form a thick liquid that bonds with the concrete surface, creating a durable and seamless coating.

Benefits:

– Enhanced durability: Epoxy coatings create a tough surface that can withstand heavy vehicles and foot traffic.

– Chemical resistance: They are highly resistant to oil spills, chemicals, and stains.

– Aesthetic appeal: With various colors and finishes available, epoxy coatings can transform your garage into a visually appealing space.

FAQs:

Q: How long does it take to install an epoxy coating?

A: The installation process typically takes around 2-3 days. This includes surface preparation, application of the epoxy coating, and curing time.

Q: Can I install an epoxy coating myself?

A: While DIY kits are available, it is recommended to hire a professional for optimal results. Proper surface preparation and application techniques are crucial for the longevity of the coating.

2. Polyurea Coatings:

Polyurea coatings are another excellent option for garage floor resurfacing. They are a type of polymer coating that offers exceptional durability and chemical resistance. Unlike epoxy coatings, polyurea coatings cure quickly, allowing for a faster installation process.

Benefits:

– Rapid curing time: Polyurea coatings can be installed in as little as one day, minimizing downtime.

– Superior flexibility: They can withstand temperature fluctuations without cracking or peeling.

– High abrasion resistance: Polyurea coatings provide excellent protection against wear and tear.

FAQs:

Q: Are polyurea coatings suitable for outdoor use?

A: Yes, polyurea coatings are highly resistant to UV rays and can be used for both indoor and outdoor applications.

Q: Can polyurea coatings be applied over existing epoxy coatings?

A: Yes, polyurea coatings can bond well with properly prepared epoxy surfaces. However, it is essential to ensure that the existing epoxy coating is in good condition and has proper adhesion to the concrete.

II. Surface Preparation: The Key to Long-lasting Results

Proper surface preparation is crucial for the success and longevity of any garage floor resurfacing project. Here are some essential steps involved in surface preparation:

1. Cleaning:

Before applying any resurfacing product, it is vital to thoroughly clean the garage floor. Remove any dirt Or debris using a broom or vacuum cleaner. For stubborn stains or spills, use a degreaser or concrete cleaner to ensure a clean surface for the coating to bond to.

2. Repairing Cracks and Holes:

Inspect the garage floor for any cracks or potholes. Use a concrete patching compound to fill in these imperfections and smooth them out. It is important to address these issues before applying the resurfacing product to prevent further damage and ensure a seamless finish.

3. Diamond Grinding:

To enhance adhesion, it is recommended to diamond grind the surface of the garage floor. This process removes any existing coatings, roughens the surface, and opens up the pores of the concrete, allowing for better penetration of the resurfacing product.

4. Moisture Testing:

Moisture can affect the adhesion and performance of resurfacing products. Perform a moisture test on the concrete surface using a moisture meter. If excessive moisture is detected, it may be necessary to use a moisture barrier or take additional measures to mitigate moisture issues.

5. Priming:

Applying a primer can further enhance adhesion and ensure a strong bond between the garage floor and the resurfacing product. Follow the manufacturer’s instructions for proper application and drying time of the primer.

III. Choosing the Right Resurfacing Product for Your Garage Floor

When selecting a resurfacing product for your garage floor, consider factors such as durability, chemical resistance, installation time, and aesthetic appeal. Epoxy coatings and polyurea coatings are popular choices for their benefits and versatility. Consult with a professional to determine the best option for your specific needs and budget.

In conclusion, garage floor resurfacing can improve the durability, appearance, and functionality of your space. Proper surface preparation and selecting the right resurfacing product are key to achieving long-lasting results. Whether you choose epoxy coatings or polyurea coatings, hiring a professional can ensure optimal installation and maximize the benefits of your garage floor resurfacing project.