Garage Floor Epoxy Temperature

Related Images about Garage Floor Epoxy Temperature

Epoxy Garage Floor Installers Epoxy Floor Coating Company

Read mixing directions very carefully to insure proper specifications are mixed. Why don't we enumerate some reason why you should select this particular kind of flooring product for your next storage area or maybe dealer flooring project. Several of the kits are available with flakes to add to or maybe scatter over the epoxy once it's been applied.

Garage Floor Epoxy Perth Designer Resin Flooring Garage Floor Coatings

These are the causes that floor epoxy coatings are utilized in a variety of areas including institutions, schools, government facilities, office buildings, showrooms, factories, warehouses, kennels, garage, and hospitals demanding industrial flooring must have. It is not hard to use hence saving on labor. Some of the most desired colors for garage flooring are grey, taupe, charcoal, and beige.

5 Things To Do Before Tackling Garage Floor Coatings – Epoxy Dallas

It's dust free as well as unwilling to acids, suitable for any business. Epoxy flooring is mostly used in a number of locations, including basements, and car port flooring surfaces, indoor patios, retail stores, restaurants, hospitals, manufacturing facilities, and laboratories, that all demand strong, durable flooring. But epoxy ensures that floors continue to be intact for long period of time.

Tips for Installing Garage Floor Epoxy in Cold Weather All Garage Floors

Garage Renovation Solutions: Polyurea Garage Floor – Benefits

Garage Floor Coating Costs – Breaking Up The Spend

4 Reasons your DIY garage epoxy flooring may fail Epoxy Blog

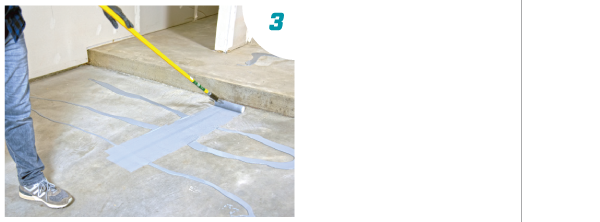

How To Apply Epoxy To a Garage Floor – Bunnings New Zealand

Surface preparation of epoxy flooring for garage – YouTube

How to Remove Epoxy Coating from a Garage Floor DoItYourself.com

Commercial Garage Floor Coating

Garage Floor Preparation Coating – Carpet Vidalondon

Epoxy Floor Kit Canada – Metallic Epoxy Floor Kit Cost Epoxy Floor / A garage floor needs to

Patio & Exterior Concrete Coatings Distinctive Garage Floors – Distinctive Garage Floors

Related Posts:

- White Epoxy Basement Floor

- Ardex Epoxy Flooring

- Commercial Garage Floor Epoxy

- Elite Crete Epoxy Floors

- Epoxy For Penny Floor

- H&c Shield Crete Garage Floor Epoxy

- Epoxyshield Garage Floor Coating Kit

- Epoxyshield Basement Floor Coating

- Epoxy Resin For Floor Tiles

- Red Epoxy Floor Paint

Garage Floor Epoxy Temperature: Understanding the Impact on Performance

The temperature of the environment plays an integral role in how well epoxy adheres to a garage floor. When applying epoxy, it is important to understand the impacts of temperature on performance and longevity. This article will discuss the importance of temperature when applying epoxy to garage floors, as well as provide tips on how to ensure the best results.

What is Epoxy?

Epoxy is a two-part resin system that provides a durable and attractive coating for garage floors. It is made up of a base resin and a hardener that reacts chemically when mixed together. Once applied, epoxy can create a hard, waterproof surface that is resistant to damage from salt, oil, gasoline, and other chemicals.

When Is the Best Time to Apply Epoxy?

It is generally recommended that epoxy be applied when temperatures are between 50°F (10°C) and 90°F (32°C). In order for the epoxy to properly cure and form a strong bond with the floor, temperatures should not drop below 50°F (10°C), or exceed 90°F (32°C). If the temperature drops too low or rises too high during application, it can cause problems with adhesion and curing. Additionally, it is important to avoid applying epoxy in direct sunlight or windy conditions as this can also lead to poor adhesion and curing.

What Happens if Temperatures Drop Below 50°F (10°C)?

If temperatures drop below 50°F (10°C) during application, it can cause several issues with the curing process. The most common problem occurs when there is insufficient heat for the epoxy to cure properly. This can lead to a weak bond between the epoxy and the surface of the garage floor which may lead to peeling or cracking over time. Additionally, if temperatures drop too low during application it can cause bubbling or wrinkling in the finish which may lead to an uneven surface.

What Happens if Temperatures Rise Above 90°F (32°C)?

When temperatures rise above 90°F (32°C), it can cause similar problems as those caused by temperatures dropping below 50°F (10°C). The heat can cause bubbles or wrinkles in the finish which may lead to an uneven surface texture or poor adhesion over time. Additionally, excessively high temperatures can speed up the curing process which may result in a weaker bond between the epoxy and garage floor.

How Can I Ensure Optimal Results When Applying Epoxy?

In order to ensure optimal results when applying epoxy to a garage floor, it is important to monitor temperatures before and during application. The ideal temperature range for applying epoxy is between 50°F (10°C) and 90°F (32°C). It is important that these temperatures are not exceeded or dropped below during application as this could lead to poor adhesion or bubbling/wrinkling in the finish. Additionally, it is important to avoid direct sunlight or windy conditions as this can also impact performance and longevity. It is also recommended that you test any sealers before applying them over top of your ep Oxy.

What is the ideal temperature to apply garage floor epoxy?

The ideal temperature to apply garage floor epoxy is between 65 and 85 degrees Fahrenheit. It is important to note that temperatures can vary depending on the type of product used. It is important to check the product instructions for the recommended temperatures. Additionally, it is important to avoid applying epoxy in direct sunlight or windy conditions as this can also lead to poor adhesion and curing.What is the best time of year to apply garage floor epoxy?

The best time of year to apply garage floor epoxy is during the spring or summer months when temperatures are between 60-80 degrees Fahrenheit. This will ensure that the epoxy cures properly and provides a long lasting finish. Additionally, it is important to avoid applying epoxy in direct sunlight or windy conditions as this can also lead to poor adhesion and curing.What is the difference between epoxy and polyurethane garage floor coatings?

Epoxy garage floor coatings are made of a two-part system of resin and hardener. When mixed together, they form an extremely hard, durable and long-lasting coating that is resistant to chemicals, stains, and water. Epoxy coatings provide a glossy finish and come in a variety of colors.Polyurethane garage floor coatings are made with a single component that cures with moisture. They do not require mixing like epoxy coatings and typically dry faster. Polyurethane coatings provide a more matte finish compared to epoxy coatings and are slightly less durable and resistant to chemicals, stains, and water.

What are the advantages and disadvantages of epoxy and polyurethane garage floor coatings?

Advantages of Epoxy Garage Floor Coating:• Durability – Epoxy coatings are known to be resilient and extremely durable. This makes them ideal for garage floor surfaces that will be exposed to a lot of wear and tear over time.

• Low Maintenance – Epoxy coatings are easy to clean and maintain. They can be wiped down with a damp cloth or mop, making them ideal for busy households that don’t have a lot of time to devote to deep cleaning.

• Waterproof – Epoxy coatings are typically waterproof, making them ideal for garage floors that may be exposed to water or other liquids. This helps protect the underlying surface from damage caused by moisture.

Disadvantages of Epoxy Garage Floor Coating:

• Cost – Epoxy coatings can be expensive, especially when compared to other options such as paint or sealants.

• Installation – Epoxy coatings require special tools and techniques to install properly, and the process can be time consuming. If not done correctly, the coating may not last as long as expected or it could peel off over time.

Advantages of Polyurethane Garage Floor Coating:

• Durability – Polyurethane coatings are incredibly durable and can withstand high levels of wear and tear over time. This makes them ideal for garage floors that will see a lot of traffic.

• Flexibility – Polyurethane coatings are more flexible than epoxy, which means they can better withstand temperature changes or shifting in the concrete surface underneath.

• Color Options – Polyurethane coatings come in a variety of colors, so you can customize your garage floor to fit your style.

Disadvantages of Polyurethane Garage Floor Coating:

• Cost – Polyurethane coatings tend to be more expensive than epoxy coatings, making them less budget-friendly for some homeowners.

• Installation – Installing polyurethane coatings is more difficult than epoxy because it requires specialized tools and techniques. If not done correctly, the coating may not last as long as expected or it could peel off over time.