Floating Concrete Floor Slab

Related Images about Floating Concrete Floor Slab

Pour a Floating Concrete Floor: 6 Steps (with Pictures)

Polished concrete flooring is an excellent approach to wisely use resources. Concrete floor takes some time to warm up, but is quite effective from possessing that heat in, which means the home of yours will stay warm on winter nights. Maintaining the concrete floor coating of yours is simple. Polished concrete floors are really easy to keep and take care of.

Pour a Floating Concrete Floor : 6 Steps (with Pictures) – Instructables

Another simple and elegant way of using polished concrete that can even decrease costs on the new home project of yours is making the foundation an entire slab that even operates as the floor. Last but not least, polished concrete may be used not only for your flooring. Concrete cleansing agents are specially created to get rid of ground in dirt and leave behind a pleasing glow on polished concrete floor.

Completed concrete ground floor slab Flickr – Photo Sharing!

Concrete floors may be scored to create a pattern by going for superficial cuts who have a circular saw. Along with this features concrete floorings are starting to be really popular day by day and nearly all individuals are opting for the same.

Can you install hardwood floors on concrete Flooring Ideas Tag Hardwood floors, Concrete

Floating Subfloor Over Concrete Slab – Vintalicious.net

concrete RAFT FORM WORK – Google Search Concrete, Concrete slab, Slab

floating foundation – Google Search Const150 Chapter 2 Concrete slab, Slab foundation

How to Pour a Perfect Concrete Slab Concrete slab, Pouring concrete slab, Poured concrete patio

Concrete Slab Repair In Calgary, Lethbridge, Medicine Hat, AB Sinking & Settling Concrete

Easy way to insulate your concrete floor..Sing Honeycomb Panels – YouTube

Building on existing concrete slab slab beim führenden marktplatz für gebrauchtmaschinen kaufen

Installing vapor barrier before pouring concrete slab – YouTube

CONCRETE FLOOR SLAB – SECOND POUR The New Zealand’s First Passive House

Is a Concrete Shed Base what you need?

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction

Floating concrete floor slabs are an innovative and modern solution for creating a durable, level and even surface for various types of flooring. By using floating concrete slabs, you can create a perfectly flat and level surface that is much stronger than traditional methods. Floating concrete floor slabs are also very cost-effective as they are easy to install and require minimal maintenance. This article will discuss the benefits of floating concrete floor slabs, the installation process and some frequently asked questions about this type of flooring.

What Are Floating Concrete Floor Slabs?

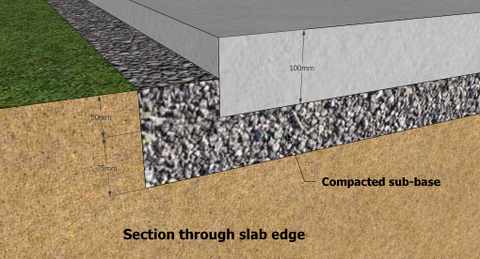

Floating concrete floor slabs are a type of poured concrete slab that is not connected to any other structure or foundation. Instead, these slabs are secured to the ground with a special adhesive material which allows them to “float” above the ground. This makes them ideal for use on uneven or unstable surfaces such as soil, gravel or sand. The slabs are usually 2-4 inches thick and can be used for both interior and exterior applications.

Advantages of Floating Concrete Floor Slabs

Floating concrete floor slabs offer many advantages over traditional methods of flooring. One of the most significant benefits is that they provide a perfectly level and even surface that is much stronger than traditional methods. This makes them ideal for use in areas where stability is key such as garages and workshops. In addition, since they are not connected to any other structure or foundation, they can be installed relatively quickly and easily with minimal disruption to the existing space. Finally, floating concrete floor slabs require very little maintenance once installed which makes them a cost-effective solution in the long run.

Installation Process

The installation process for floating concrete floor slabs is relatively straightforward but it is important to ensure that all steps are followed correctly in order to achieve the desired result. First, the area must be prepared by removing any existing debris or vegetation from the surface. Next, a bedding layer must be applied which helps to level out the surface for maximum stability. After this has been done, the floating concrete slab can then be placed onto the bedding layer using an adhesive material such as mortar or grout. Once all joints have been sealed with additional mortar or grout, the slab can then be leveled using a spirit level before it is left to set overnight.

FAQs About Floating Concrete Floor Slabs

Q: What materials are used for floating concrete floor slabs?

A: Floating concrete floor slabs are usually made from a combination of sand, cement and aggregate materials which are mixed together with water until they form a thick paste-like consistency. This mixture is then poured into forms which are left in place until it sets overnight before being removed and allowed to dry completely before use.

Q: How long do floating concrete floor slabs last?

A: When installed correctly, floating concrete floor slabs can last up to 25 years with minimal maintenance required throughout this period in order to maintain their strength and integrity.

Q: Are there any special considerations when installing floating concrete floor slabs?

A: Yes, it is important to ensure that all joints between the individual pieces of slab are properly sealed with mortar or grout in order to prevent water from entering underneath them which could cause them to become unstable over Time. Additionally, it is also important to ensure that the surface of the slabs are completely level before they are left to set overnight.

What are the advantages of using a floating concrete floor slab?

1. Improved sound insulation: Floating concrete floor slabs provide a good level of sound insulation, allowing for quieter living and working environments.2. Cost savings: Floating concrete floor slabs are cost effective as they require less excavation and labor costs compared to other foundations.

3. Increased structural integrity: Floating concrete floor slabs provide additional structural support and stability, making them an ideal choice for high-traffic areas or areas subject to seismic activity.

4. Quick installation: Floating concrete floor slabs are easier and faster to install than other foundation types, saving time and labor costs.

5. Versatility: Floating concrete floor slabs can be used in a variety of applications, from residential homes to commercial buildings.

What is the difference between a floating concrete floor slab and a traditional concrete slab?

A floating concrete floor slab is designed to rest on a bed of sand or fine gravel, and is typically placed over an existing concrete or asphalt surface. It is not connected to the underlying substrate and instead relies on its own structural integrity. This type of flooring can be used to reduce sound transmission, minimize cracking in the underlying substrate, and provide thermal insulation.A traditional concrete slab is poured directly into a prepared form, and is connected to the underlying substrate with rebar or wire mesh. This type of flooring provides superior strength and durability compared to a floating slab, but does not provide the same degree of sound insulation or thermal insulation as a floating slab.