Epoxy Shield Industrial Floor Coating

Related Images about Epoxy Shield Industrial Floor Coating

Rust-Oleum Epoxy Shield Garage Floor Coating Kit Truworth Homes

Epoxy flooring is a kind of surface coating which is going to protect a concrete floor from frequent wear and tear. A floor sealed with epoxy is going to have a long life working with a huge amount of traffic. As soon as these 2 are mixed they are poured over an existing flooring or maybe base content to be able to make a protective coating. Epoxy is easy to clean, and impervious to bacteria and mold.

Epoxy Floor Coating Video Floor Coatings

You will also need a catalyst, which happens to be an element of a multi part epoxy device that can cause the resin to harden. High quality epoxy resin is employed to upgrade surfaces, obtain colored consequences, protect floors against corrosion, and attain a water tight outcome. You can have some color that you want that can blend perfectly with your house color scheme.

Basement Flooring Options Epoxy Finish – Premier Concrete Coatings Columbus Ohio Decorative

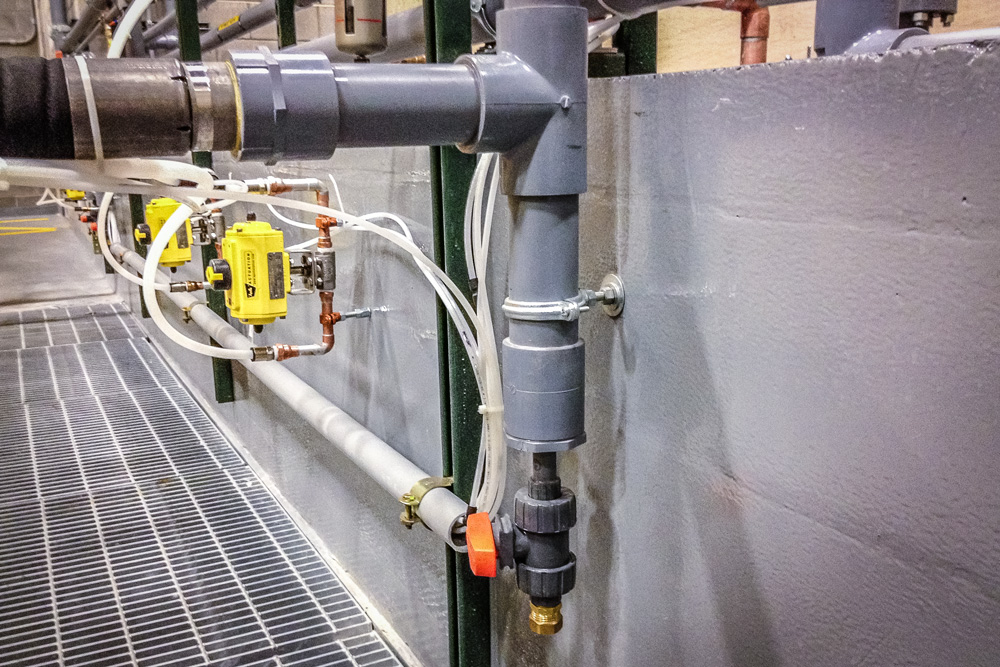

Epoxy flooring isn't cheap as well as the cost of a floor is dependent on the dimensions of the surface to be covered, obviously. Epoxy is resilient adequate to resist many stains & still maintain an appealing floor. In addition to choosing a flooring color, buyers also have an opportunity to improve their floor's uniqueness with anti slip flecks. Epoxy flooring is frequently used in an industrial environment.

FLOOR-NU DTO (Direct to Oil) Epoxy Flooring System

Epoxy Chemical Resistant Floor Coatings, Epoxy Barrier Coating With Flooring Service – Kohinoor

Floor Shield Coating Dealer Opportunities Epoxy Floor Business Start Up

POLYURETHANE & EPOXY FLOOR COATINGS, Epoxy Flooring, 343, Protective Coatings & Onsite Coating

Epoxy Coating Systems Diama-Shield

Commercial Epoxy Flooring Epoxy Floor Coating Floorguard.com

New design big area epoxy floor coating removing grinder cement terrazzo stone floor grinding

Epoxy Floor Coatings C.A. Reed Associates

Epoxy Floor Coatings www.SafeDry.com 877-824-0501 – YouTube

Rust-Oleum EPOXYShield Professional Floor Coating

Wholesale Trader of Waterproofing Chemical & Epoxy Flooring by New Era Technique Private Limited

Related Posts:

- How To Apply Epoxy Shield Garage Floor Coating

- Epoxy Garage Floor Paint Reviews

- Metallic Epoxy Floor Designs

- Quikrete Epoxy Garage Floor Coating Kit Reviews

- Metallic Epoxy Flooring System

- Dupont Epoxy Floor Paint

- White Epoxy Basement Floor

- Ardex Epoxy Flooring

- Commercial Garage Floor Epoxy

- Elite Crete Epoxy Floors

Epoxy Shield Industrial Floor Coating: A Comprehensive Solution for Durable and Attractive Floors

Introduction:

Industrial facilities require flooring solutions that can withstand heavy foot traffic, vehicle movement, and chemical spills while maintaining a clean and professional appearance. In such demanding environments, Epoxy Shield Industrial Floor Coating emerges as a reliable and cost-effective solution. This article will delve into the various aspects of this remarkable product, from its composition and application process to its benefits and frequently asked questions.

Composition of Epoxy Shield Industrial Floor Coating:

Epoxy Shield Industrial Floor Coating is a two-component system that consists of epoxy resin and a hardener. When mixed together, they undergo a chemical reaction known as curing, resulting in a durable and resilient coating. This coating is formulated using high-quality materials that offer exceptional resistance against abrasion, impact, chemicals, and UV rays. Additionally, it provides a smooth and glossy finish that enhances the overall aesthetics of the floor.

Application Process:

Before applying Epoxy Shield Industrial Floor Coating, proper surface preparation is crucial to ensure optimal adhesion and longevity. The surface should be thoroughly cleaned to remove any debris, grease, or oil stains. Depending on the condition of the existing flooring, mechanical methods such as grinding or shot blasting may be required to create a roughened surface for better adhesion.

Once the surface is prepared, the epoxy resin and hardener are mixed together according to the manufacturer’s instructions. It is essential to follow the mixing ratios precisely to achieve optimal results. The mixture is then applied using a roller or brush in thin coats, allowing sufficient drying time between each layer. Multiple coats are typically recommended to achieve the desired thickness and durability.

Benefits of Epoxy Shield Industrial Floor Coating:

1. Durability: Epoxy Shield Industrial Floor Coating offers exceptional durability that can withstand heavy machinery, forklift traffic, and other rigorous activities commonly found in industrial settings. Its resistance to abrasion and impact ensures that the floor maintains its integrity even under challenging conditions.

2. Chemical Resistance: Industrial facilities often handle corrosive chemicals that can damage unprotected floors. Epoxy Shield Industrial Floor Coating provides excellent resistance against a wide range of chemicals, including acids, alkalis, solvents, and oils. This chemical resistance not only protects the floor but also simplifies cleaning and maintenance.

3. Easy Maintenance: Maintaining a clean and hygienic environment is crucial in industrial facilities. The seamless and non-porous nature of Epoxy Shield Industrial Floor Coating prevents the accumulation of dirt, dust, and bacteria, making it easy to clean with regular sweeping and mopping. Additionally, its high-gloss finish adds a professional touch to the space.

4. Enhanced Safety: One of the primary concerns in industrial environments is safety. Epoxy Shield Industrial Floor Coating can be customized with slip-resistant additives to provide better traction, reducing the risk of slips and falls. This feature is particularly vital in areas prone to wet conditions or where spills are common.

Frequently Asked Questions:

Q1: How long does it take for Epoxy Shield Industrial Floor Coating to cure?

A1: The curing time of Epoxy Shield Industrial Floor Coating depends on various factors such as temperature, humidity, and the specific product used. Generally, it takes around 24-48 hours for the initial cure, during which the floor should not be subjected to heavy traffic or moisture. Full cure typically occurs within 7 days, but it is recommended to wait at least 72 hours before placing any heavy objects or machinery on the floor.

Q2: Can Epoxy Shield Industrial Floor Coating be applied to all types of surfaces?

A2: Epoxy Shield Industrial Floor Coating can be applied to a variety of surfaces including concrete, metal, and wood. However, it is important to ensure that the surface is properly prepared and in good condition before applying the coating.

Q3: How long does Epoxy Shield Industrial Floor Coating last?

A3: The lifespan of Epoxy Shield Industrial Floor Coating depends on various factors such as the level of traffic and use, maintenance practices, and environmental conditions. With proper installation and regular maintenance, it can last for several years.

Q4: Can Epoxy Shield Industrial Floor Coating be repaired if it gets damaged?

A4: Yes, Epoxy Shield Industrial Floor Coating can be repaired if it gets damaged. Minor damages such as scratches or chips can be repaired by sanding down the affected area and applying a new layer of epoxy. For more extensive damages, it may be necessary to remove the entire coating and reapply a new one.

Q5: Is it possible to add color or patterns to Epoxy Shield Industrial Floor Coating?

A5: Yes, Epoxy Shield Industrial Floor Coating can be customized with different colors and patterns. This allows for creative design options and the ability to match the flooring with the overall aesthetic of the facility. Customization options include solid colors, metallic finishes, or decorative flakes.

In conclusion, Epoxy Shield Industrial Floor Coating offers exceptional durability, chemical resistance, easy maintenance, and enhanced safety for industrial facilities. It is important to follow proper surface preparation and application procedures to ensure optimal adhesion and longevity. The curing time can vary, and it is recommended to wait at least 72 hours before placing heavy objects on the floor. Epoxy Shield Industrial Floor Coating can be applied to various surfaces and can be repaired if necessary. Customization options are available for adding color and patterns to the coating.