Epoxy Garage Floor In Cold Weather

Related Images about Epoxy Garage Floor In Cold Weather

The Best Garage Floor Coating Life On Virginia Street

Epoxy flooring is made of polymer materials will start their lives as a liquid and then may be transformed into a strong polymer through a chemical reaction. The Interactive Designer program on these sites is in addition a fantastic resource to match up with up base coats as well as flooring flecks. Which means that designers can select a color which compliments, contrasts, or perhaps highlights the area they are reinventing.

Epoxy Garage Floor Installers Corona Garage Epoxy Flooring

Some epoxy coatings require a certain amount of time to be reserved between blending and program, which is called induction time. Also on the positive side, they are easier to work with and wash up compared to 100 % solid epoxy. Purchase epoxy in a 2 part package to see to it that the resin and hardener are agreeable. Epoxy is a durable and hard information, which is why it is nicely suited to flooring applications.

Garage Floor Epoxy: Garage Floor Epoxy Temperature

This’s exactly why, with regards to renovating you floors, you should put in epoxy flooring. Thus to be precise, epoxy resins have fairly endless uses & benefits. Therefore, in case you are into redefining garage or perhaps warehouse flooring, try out epoxy coating for traditional pro-appeal to the floor. Thus, you are going to need to rob a polyurethane or latex floor before applying epoxy.

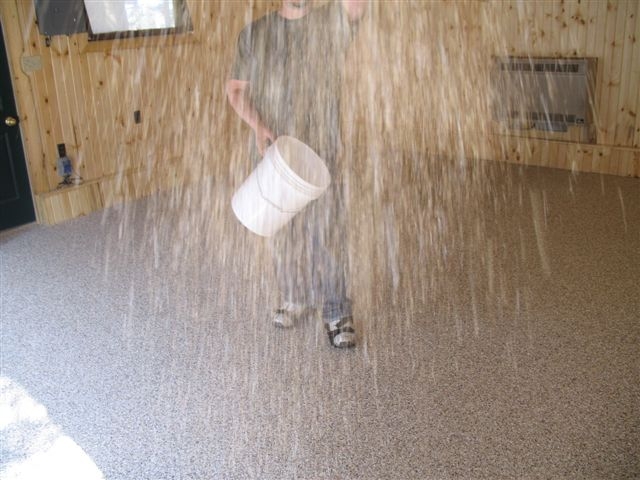

Waterborne Epoxy Garage Floor Coating Training in Buckeye, AZ Slide-Lok Garage Floors

Monster Cote – Chip / Flake Epoxy Floor, Epoxy Garage Floor Monster Cote

Legacy Industrial’s Blog Site: Professional Results Full Flake Broadcast Epoxy Polyaspartic

How to Apply an Epoxy Garage Floor Coating

Our Epoxy Garage Floor Coating: How It’s Holding Up After 2 Winters – Andrea Dekker

Garage Floor Installation in Cold Weather

How To Install Epoxy Garage Floor Coating Lifehacker Australia

ARMOUR® Chip™ Polyaspartic Garage Flooring in Cleveland, OH Decorative Flake Flooring Epoxy

Minnesota Garage Floor Coatings Polyurea Garage Coatings Minneapolis & St Paul Floor Coatings

Epoxy Floor Textures Brew Floors

Epoxy Garage Floors Near Me – Madison Art Center Design

Related Posts:

- Metallic Epoxy Flooring System

- Dupont Epoxy Floor Paint

- White Epoxy Basement Floor

- Ardex Epoxy Flooring

- Commercial Garage Floor Epoxy

- Elite Crete Epoxy Floors

- Epoxy For Penny Floor

- H&c Shield Crete Garage Floor Epoxy

- Epoxyshield Garage Floor Coating Kit

- Epoxyshield Basement Floor Coating

Epoxy Garage Floor In Cold Weather: A Comprehensive Guide

When it comes to upgrading your garage floor, epoxy coating is a popular choice for its durability, aesthetics, and ease of maintenance. However, one common concern among homeowners is how epoxy garage floors hold up in cold weather conditions. In this comprehensive guide, we will delve into the effects of cold weather on epoxy garage floors and provide you with valuable tips on how to ensure the longevity and performance of your epoxy coating during the winter months.

Effects of Cold Weather on Epoxy Garage Floors

Cold weather can have a significant impact on the performance and durability of epoxy garage floors. One of the primary concerns is that low temperatures can slow down the curing process of the epoxy resin, leading to improper adhesion and a weaker bond between the coating and the concrete substrate. This can result in delamination, chipping, and peeling of the epoxy coating.

Additionally, cold weather can also cause the epoxy to become more viscous, making it difficult to apply evenly and smoothly. This can result in an uneven finish with visible brush marks or roller lines. Furthermore, extreme cold temperatures can cause the epoxy to become brittle and prone to cracking under heavy loads or impact.

Tips for Installing Epoxy Garage Floors in Cold Weather

1. Choose a High-Quality Epoxy System: When installing an epoxy garage floor in cold weather, it is crucial to choose a high-quality epoxy system that is designed to withstand low temperatures. Look for an epoxy coating that is specifically formulated for cold weather applications and provides excellent adhesion and durability even in freezing temperatures.

2. Prepare the Surface Properly: Proper surface preparation is key to ensuring the adhesion and longevity of your epoxy garage floor. Make sure to thoroughly clean and etch the concrete substrate before applying the epoxy coating. This will help remove any dirt, oil, or contaminants that can interfere with proper adhesion.

3. Monitor Temperature and Humidity Levels: It is essential to monitor temperature and humidity levels during the installation process to ensure optimal conditions for curing. Ideally, the temperature should be above 50°F (10°C) for at least 24 hours before and after applying the epoxy coating. Additionally, maintain proper ventilation to promote proper curing and prevent moisture buildup.

4. Use a Heater or Heat Gun: If you are installing an epoxy garage floor in extremely cold conditions, consider using a heater or heat gun to warm up the concrete substrate before applying the epoxy coating. This will help improve adhesion and ensure a smooth finish.

5. Allow Sufficient Curing Time: After applying the epoxy coating, allow sufficient curing time as per the manufacturer’s instructions. Avoid walking or driving on the newly coated surface until it has fully cured to prevent damage or premature wear.

Frequently Asked Questions:

Q: Can I install an epoxy garage floor in below-freezing temperatures?

A: While it is not ideal, you can still install an epoxy garage floor in below-freezing temperatures if you take proper precautions such as using a high-quality cold weather epoxy system, warming up the concrete substrate, and monitoring temperature and humidity levels during installation.

Q: How long does it take for an epoxy garage floor to cure in cold weather?

A: The curing time for an epoxy garage floor in cold weather may be longer than usual due to lower temperatures. It is recommended to allow at least 72 hours for full curing before subjecting the surface to heavy loads or traffic.

Q: Will my epoxy garage floor Be more prone to cracking in cold weather?

A: Yes, epoxy garage floors installed in cold weather may be more prone to cracking due to the brittleness of the epoxy coating in low temperatures. To prevent cracking, it is essential to choose a high-quality epoxy system designed for cold weather applications and take proper precautions during installation, such as warming up the substrate and allowing sufficient curing time. Overall, installing an epoxy garage floor in cold weather is possible with the right preparation and precautions. By choosing a high-quality cold weather epoxy system, properly preparing the surface, monitoring temperature and humidity levels, using heaters or heat guns if necessary, and allowing sufficient curing time, you can ensure a durable and long-lasting finish even in freezing temperatures. If you have any specific concerns or questions about installing an epoxy garage floor in cold weather, it is always best to consult with a professional for guidance.