Epoxy Floor Coating Equipment

Related Images about Epoxy Floor Coating Equipment

WOOSTER PRODUCTS Anti-Slip Epoxy Anti-Slip Floor Coating, Clear, 1 gal – 45TR91WAS20.CLR – Grainger

If your epoxy floor paint is solvent-based it's much more dangerous but stronger than epoxy which is water based. The benefits are many with regards to installing epoxy flooring in your shop or garage. Manufacturing epoxy floor covering things stand above the rest in delivering the highest quality and best performance in manufacturing floor applications.

Epoxy Flooring Cleaner Epoxy Floor

Whatever kind of shade you've in mind, you are able to get the color of paint you're searching for. The floors are extremely easy to clean and maintain, and they last for several years even in excessive traffic areas. You are able to additionally repair your epoxy flooring in case you get a chip or damage the floor in some way. The paint is thinner than the solids, nevertheless, and won't survive as long.

CPC Floor Coatings Industrial Epoxy Floor Coatings

With very good surface preparation, manufacturing epoxy floor coating programs enjoy a high possibility of success. It lays very well on many sorts of surfaces like metal, concrete, wood and tile and is resistant to most strong chemicals making for a durable and long-lasting surface and several color may possibly be added to the epoxy for a little bit of flare. Epoxy concrete paints are extremely durable and will tolerate pressure which is high.

Epoxy Floor Coatings Epoxy Flooring Industrial Flooring

Commercial Epoxy Flooring – Canadian Pros Painting: Trusted Calgary Painters – Commercial

Epoxy & Urethane Floor Coating Services in El Paso, Texas

Polytech Coatings

Industrial Epoxy Floor Coating Service, Resins, ID: 19302299055

RAL 1011 Brown beige – epoxy floor incl. primer – EPODEX – United Kingdom

FLOOR FINISH PRODUCTS

Metallic Epoxy Floor Coating Kit Floor Paints Resincoat UK

Why Choose Epoxy Flooring Systems for Industrial Floor Coating

Industrial Epoxy Floor Coating Epoxy Flooring – Protective Industrial Polymers

Epoxy Resin Penny Floor – GlassCast

Related Posts:

- Epoxy Garage Floor Paint Reviews

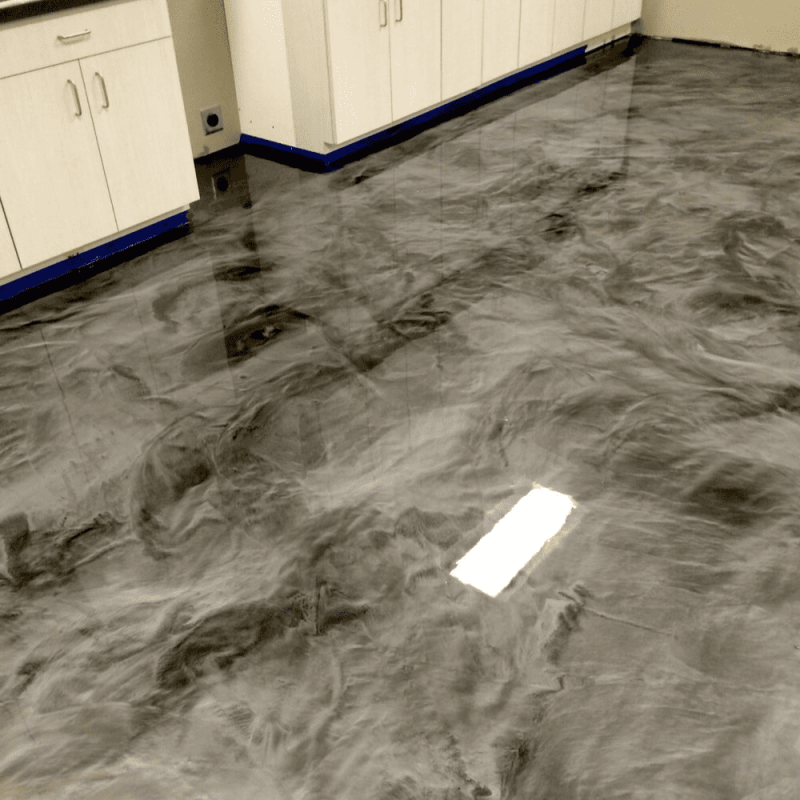

- Metallic Epoxy Floor Designs

- Quikrete Epoxy Garage Floor Coating Kit Reviews

- Metallic Epoxy Flooring System

- Dupont Epoxy Floor Paint

- White Epoxy Basement Floor

- Ardex Epoxy Flooring

- Commercial Garage Floor Epoxy

- Elite Crete Epoxy Floors

- Epoxy For Penny Floor

Epoxy Floor Coating Equipment: Everything You Need to Know

Epoxy floor coating is becoming increasingly popular in industrial, commercial and residential settings. But creating an epoxy floor can be a complex task. That’s why having the right equipment is essential for a successful installation. In this article, we’ll take a look at all the epoxy floor coating equipment you need to make sure your project is done right.

Substrate Preparation Equipment

Before you can begin applying an epoxy floor coating, the surface must be properly prepared. This means cleaning it, repairing any damage and filling in any cracks. The right substrate preparation equipment is essential for getting the job done correctly.

Cleaning: To remove dirt, dust and other debris from the surface, you will need a vacuum cleaner or pressure washer. Alternatively, you can use a broom to sweep away dirt and debris by hand.

Repair: If there are any cracks or holes on the surface, you will need to fill them in with a patching compound. For larger repairs, such as deep holes or large cracks, you may need to use concrete filler.

Primers: After cleaning and repairing the surface, it’s important to apply a primer before applying an epoxy floor coating. Primers help ensure that the epoxy adheres properly to the surface and will help extend its life span.

Application Equipment

Once the substrate has been properly prepared, it’s time to start applying the epoxy floor coating. There are several different types of application equipment available depending on your needs.

Brushes/Rollers: For small areas or tight spaces, brushes or rollers are ideal for applying an epoxy floor coating. They are easy to use and require minimal setup time.

Spray Guns: For larger areas or more even coverage, spray guns are perfect for applying an epoxy floor coating quickly and efficiently. They are also great for hard-to-reach places such as corners and crevices.

Airless Sprayers: Airless sprayers are best suited for large areas such as warehouses or factories as they allow you to cover more ground in less time than other application methods. They also provide excellent coverage and a smooth finish with minimal overspray.

Finishing Equipment

After applying an epoxy floor coating, it’s important to give it time to cure before walking on it or placing furniture on it. Additionally, if desired, you can add non-slip additives for extra safety or colored flakes for a decorative touch. Here’s what you need for finishing up your project:

Curing: Epoxy floors typically require 24-48 hours of curing time before they can be walked on or used for anything else. Be sure to give your coating plenty of time before using it so that it sets properly and lasts longer.

Non-Slip Additives: If desired, non-slip additives can be added to the epoxy floor coating For extra safety. These additives come in a variety of colors and finishes and can be applied after the epoxy has cured.

Colored Flakes: For a decorative touch, colored flakes can be added to the epoxy floor coating. These flakes come in a variety of colors and sizes and can be applied after the epoxy has cured.