Engineered Wood Flooring Nailer

Related Images about Engineered Wood Flooring Nailer

Hardwood Flooring Nailer for sale

As a result of our accurate sanding throughout the lamination procedure for the engineered product or service & after, pieces are more constant in height, far more consistent for feel, fit collectively tighter, with no waste, gaps and cracks now filled, and virtually no sanding needed after install until you should do a light display or buff. You can still have that enticing hardwood warmth and appeal with an engineered flooring.

Carpentry Power Tools and Their Uses

Last but not least, the acrylic-impregnated type of wood flooring is a mix of solid and acrylic timber. If you're only going to be at a property for a particular period, or perhaps you're a landlord flooring your properties for hard-usage, you'd probably opt for laminate as it strikes a good balance of cost/quality, whereas a family members looking to make someplace the home of theirs for a prolonged time might make the leap and get solid wood.

Installing Engineered Hardwood Flooring: Part 1 – YouTube

Floors that we will not cover allow me to share laminates or maybe any composite products that are often not wood entirely through the plank or may be made with a picture printed surface. Aged wood flooring and also troubled flooring presents a fashionable, lived in look. As expected, coupled with the expanded durability, the price per square foot improved as well, surmounting to full cost per square feet exceeding income levels of consumers with restricted incomes, until the launch of vinyl wood flooring.

Manual Floor Nailer – FLOOR

Hardwood Floor Nailer – Carpet Vidalondon

Hardwood Floor Nailer – FLOOR

Flooring nailer reaches tight areas — Coverings

Flooring Tool Rentals at A-1 Rental of Price Utah serving Carbon , Emery, Grand, Uintah, and

Installing Hardwood Floor With Finish Nailer – Nail Ftempo

26 Ideal 3 8 Hardwood Floor Nailer Unique Flooring Ideas

Bruce Hardwood Flooring Nails Or Staples TcWorks.Org

HARDWOOD FLOORING NAILERS : FLOORING NAILERS – ASM ACCESS FLOORING

How to Install an Engineered Hardwood Floor how-tos DIY

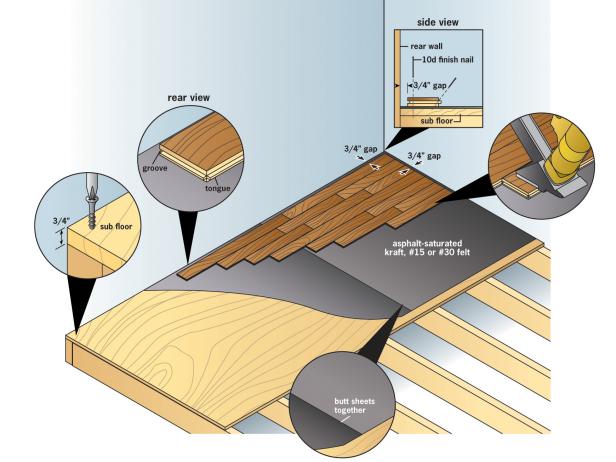

How to Install Prefinished Solid-Hardwood Flooring how-tos DIY

Related Posts:

- Wood Floor Modern Kitchen

- Wood Floor Garage Plans

- Real Wood Flooring In Kitchen

- Wood Floor Cork Underlayment

- Streak Free Wood Floor Cleaning

- Solid Wood Flooring White Washed Oak

- Engineered Wood Flooring Durability

- Wood Flooring Types Hardness

- Engineered Wood Flooring Formaldehyde Emission

- Wood Floors For Beach House

Engineered Wood Flooring Nailer: A Comprehensive Guide

Introduction:

Engineered wood flooring has gained immense popularity in recent years due to its durability, beauty, and affordability. However, installing engineered wood flooring requires specialized tools to ensure a seamless and professional finish. One such tool is an engineered wood flooring nailer. In this article, we will delve into the world of engineered wood flooring nailers, exploring their features, benefits, frequently asked questions, and more.

I. Understanding Engineered Wood Flooring Nailers:

An engineered wood flooring nailer is a pneumatic tool specifically designed for the installation of engineered wood flooring. It uses compressed air to drive specialized nails into the tongue of each plank, securely fastening them to the subfloor. This method eliminates the need for glue or adhesive and ensures a tight fit without damaging the surface of the planks.

Benefits of Using an Engineered Wood Flooring Nailer:

1. Speed and Efficiency: The use of an engineered wood flooring nailer significantly speeds up the installation process compared to traditional methods such as nailing by hand. The pneumatic force allows for precise and rapid nail placement, reducing labor time.

2. Professional Finish: Engineered wood flooring nailers ensure consistent and uniform nail placement throughout the installation process, resulting in a polished and professional-looking floor.

3. Reduced Floor Damage: Unlike other installation methods that may involve hammering nails directly onto the surface of the planks, a flooring nailer drives nails through the tongue, minimizing visible damage to the top layer of the engineered wood.

4. Enhanced Stability: The controlled force applied by a nailer helps secure each plank tightly to the subfloor, preventing movement or squeaking over time.

II. Types of Engineered Wood Flooring Nailers:

1. Manual Nailers:

Manual nailers require physical force from a mallet or hammer to drive nails into the tongue of the planks. While they are more affordable than pneumatic nailers, they require more effort and may not offer the same level of precision and speed.

2. Pneumatic Nailers:

Pneumatic nailers are powered by compressed air, making them the most efficient and commonly used type of engineered wood flooring nailer. They offer superior control, speed, and accuracy, allowing for a smooth installation process.

Frequently Asked Questions:

Q1: Can I use a regular nailer for engineered wood flooring?

A1: No, using a regular nailer may damage the delicate surface of engineered wood flooring. Engineered wood flooring nailers are specifically designed to drive nails through the tongue without causing visible damage.

Q2: Are pneumatic nailers difficult to operate?

A2: Pneumatic nailers are designed to be user-friendly and straightforward. However, it is important to follow the manufacturer’s instructions and practice proper safety precautions to ensure smooth operation.

III. Factors to Consider When Choosing an Engineered Wood Flooring Nailer:

1. Nail Size Compatibility:

Ensure that the chosen nailer is compatible with the size and type of nails recommended by the manufacturer of your engineered wood flooring. Using incorrect nails may result in subpar installation or voiding warranty.

2. Weight and Ergonomics:

Consider the weight and ergonomics of the nailer, especially if you anticipate working on large projects. A lightweight and well-balanced tool will reduce fatigue and allow for extended periods of use without discomfort.

3. Adjustable Depth Settings:

Look for a nailer that offers adjustable depth settings to accommodate varying thicknesses Of engineered wood flooring. This allows for precise nail placement and ensures the nails are driven to the correct depth without damaging the surface of the flooring.

4. Magazine Capacity:

Consider the magazine capacity of the nailer, which determines how many nails it can hold at once. A larger magazine capacity can save time by reducing the frequency of reloading.

5. Durability and Warranty:

Choose a nailer that is made from high-quality materials and offers a warranty for added peace of mind. A durable nailer will withstand regular use and provide long-lasting performance.

6. Noise Level:

Some pneumatic nailers may produce loud noise during operation. If noise is a concern, consider choosing a nailer with noise-reducing features or wearing hearing protection while using the tool.

Conclusion:

Using an engineered wood flooring nailer is the most efficient and effective way to install engineered wood floors. It ensures consistent and uniform nail placement, reduces floor damage, and enhances stability. When choosing a nailer, consider factors such as nail size compatibility, weight and ergonomics, adjustable depth settings, magazine capacity, durability and warranty, and noise level. By selecting the right nailer for your project, you can achieve a professional-looking result with ease.