Engineered Hardwood Flooring Installation Concrete

Related Images about Engineered Hardwood Flooring Installation Concrete

Hardwood Flooring and Laminate Flooring in Cumming, GACustom Home Center Inc, Cumming GA

Factory finishes cured through ultra violet light have a harder finish in general and also the factory is going to make the wood with a better number of coats to minimize harm for the long haul. With appropriate care and maintenance, it's possible to have your hardwood flooring for numerous years; also a lifetime. The most prominent element which makes hardwood become unclean is grit as well as dirt.

How to Install Engineered Click-Lock Flooring : Flooring Tips – YouTube

What exactly are the colors of the walls and furniture? You would not wish to buy hardwood flooring surfaces with a color which doesn't match those of your furniture and wall space. Engineered hardwood flooring tends to be much thinner compared to sound hardwood flooring and it is commonly glued to the subsurface although it is able to in addition be nailed or perhaps stapled.

10 Prefinished Brazilian Cherry Hardwood Flooring Amazing Design Best Flo… Cherry hardwood

New wood floors are generally sealed with urethane, polyurethane or polyacrylic sealers created to safeguard the top done surface. Choosing the correct hardwood floor wax is perfect based on the composition of the hardwood material fitted. Most warranties will say that there is an industry standard of 5 % margin for error meaning that when your entire floor is complete the maker is actually permitted to have five % belonging to the boards defective.

How to Install Prefinished Solid-Hardwood Flooring how-tos DIY

Engineered Wood Floors: What to Know Before You Buy

/empty-living-room-in-modern-apartment-578189139-58866f903df78c2ccdecab05.jpg)

Solid Wood Flooring – Academy Hardwood Flooring

Four Seasons Condo Residence – Toronto – European Flooring Group Toronto

Related Posts:

- Hardwood Floor Cupping Causes

- Hardwood Floor Tile Inlay

- Hardwood Floor Filler Putty

- Canadian Oak Hardwood Flooring

- Wood Filler Hardwood Floor Repair

- Hardwood Floor Cleaner Best

- Hardwood Floor Compass Inlay

- Hardwood Flooring For Dog Owners

- Brazilian Cherry Bamboo Hardwood Flooring

- Hardwood Floor Cleaner Vinegar Olive Oil

Introduction to Engineered Hardwood Flooring Installation on Concrete

Engineered hardwood flooring installation on concrete is a popular choice for homeowners seeking a durable and attractive flooring option. This type of flooring is made up of multiple layers of wood veneer that are glued together to create a solid base. The top layer is often made of real wood, but it can also be made from composite materials or laminate. This type of flooring is more resistant to moisture and temperature changes than traditional hardwood flooring, making it an ideal choice for areas with high moisture levels or temperatures. Additionally, engineered hardwood floors are easy to install and maintain, making them an attractive option for those looking to upgrade their home without having to break the bank. In this article, we will discuss the steps involved in installing engineered hardwood floors on concrete and provide answers to some frequently asked questions about the process.

Steps Involved in Installing Engineered Hardwood Flooring on Concrete

Installing engineered hardwood on concrete is not as difficult as one might assume. It requires some basic DIY skills and knowledge, but it can be done quickly and easily with the right tools and instructions. Here are the steps involved in the installation process:

1. Preparing the Area – The first step in installing engineered hardwood flooring on concrete is to prepare the area by cleaning it thoroughly and ensuring that any cracks, chips, or other irregularities are filled in with a suitable filler material such as patch mix or self-leveling compound. Additionally, make sure that any existing thresholds or transitions have been removed prior to installation.

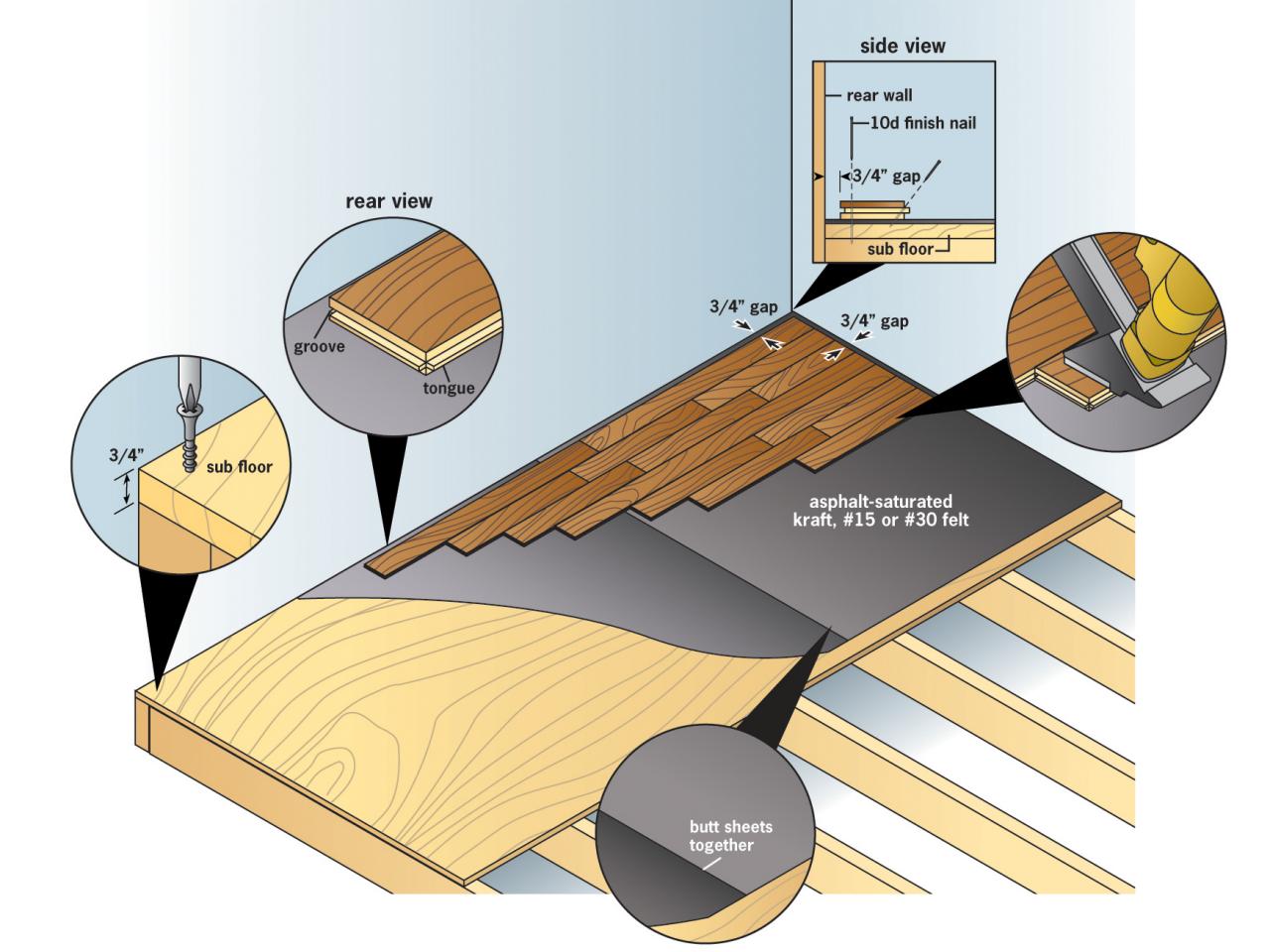

2. Subfloor Preparation – Once the area has been prepared, the next step is to install a subfloor before laying down the engineered hardwood planks. This subfloor should be made of plywood or OSB (oriented strand board) and should be screwed down securely into the concrete with concrete screws or masonry anchors. The thickness of this subfloor should be at least two inches thick for optimal results.

3. Laying Down Underlayment – Once the subfloor has been installed, you can then begin laying down underlayment over it. Underlayment helps absorb sound, provides additional insulation, and creates a softer feel underfoot when walking on the finished flooring. Make sure to roll out your underlayment evenly with no gaps or bumps for best results.

4. Installing Planks – Now it’s time to start laying down your engineered hardwood planks! Begin by measuring your room and cutting your planks accordingly so they fit perfectly within your space. Lay down your planks by starting in one corner and working your way across until you have completed one row before moving onto the next row until your entire area has been covered with planks. Make sure to leave a small gap between each plank (about 1/8” – 1/4”) for expansion purposes due to temperature changes throughout the year.

5. Finishing Touches – Finally, once all of your planks have been laid down you can add any finishing touches such as baseboard trim or quarter-round trim around doorways or other areas where there may be a slight gap between your flooring and wall surfaces for an aesthetically pleasing look once everything has been completed .

Frequently Asked Questions

Q: Do I need to use special adhesive when installing engineered hardwood on concrete?

A: Most engineered hardwood floors are designed to be installed with a floating installation method, meaning that they do not require any type of adhesive or nails to stay in place. However, you may choose to use an adhesive if desired for added security. Make sure to check the manufacturer’s instructions before doing so.

Q: How long does it take to install engineered hardwood on concrete?

A: The amount of time it takes to install an engineered hardwood floor on concrete will depend on the size of your room and the level of difficulty involved in the installation process. Generally speaking, it should take anywhere from one day for a smaller room (up to 100 sq ft) to two days or more for a larger room (more than 500 sq ft).