Cracks In Garage Floor Epoxy

Related Images about Cracks In Garage Floor Epoxy

How To: Repair cracks in a concrete garage floor before applying paint or epoxy – The Washington

Flooring is a terrific choice to make for the house, commercial business, or maybe manufacturing sector. If you do not, it's advisable to have an expert do it. They have colored chips or flakes inlaid within the floor surfaces and these lend an aesthetic and decorative very experience to the floor. The best surface to lay epoxy flooring is actually concrete, but you are able to put up epoxy flooring over surfaces which include steel as well as wood also.

Concrete Crack Repair Intricate Coatings Epoxy Specialists

There are many epoxy products with a wide range of color options to pick from. The garages these days are not only intended for parking the automobiles, but the serve different functions as well. more and More folks are turning to epoxy floor paint to earn distinct rooms in the homes of theirs and businesses look better than ever before.

Epoxy Garage Floor Crack Filler – Madison Art Center Design

An epoxy flooring coating for the warehouse of yours will make your floor able to endure the tough environments on which the damage of your fleet of factory vehicles would normally harm the floor with no epoxy covering. Nonetheless, not all flooring can hold epoxy coating. The epoxy floor paints may be offered the preferred color as per the person requirements.

DIY Epoxy Garage Floor Coating Repair – Casper, WY

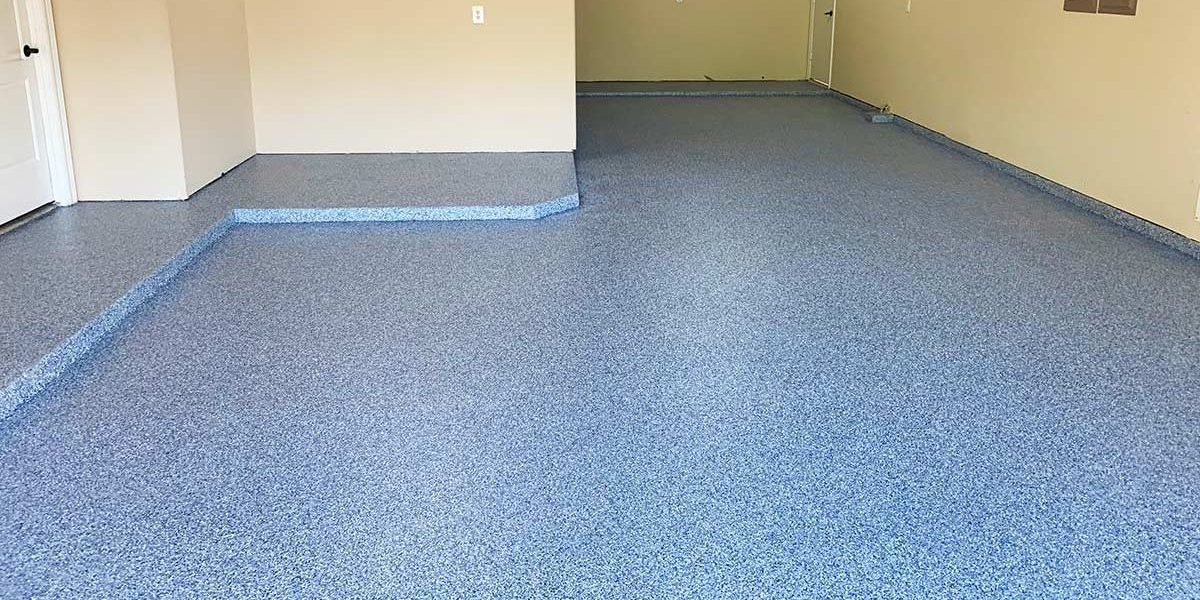

Epoxy Garage Flake Floor For a New Home – Majestic Concrete

Concrete Slab Crack Repair Instructional Video – YouTube

Garage Floors – Epoxy Coat Texas – Houston Epoxy Flooring, Industrial Coatings

Garage Floor Coatings 4x Stronger than Epoxy

Epoxy Flake Floors to Transform Your Garage – Elite Concrete Systems

Garage Epoxy Floors,LLC. – OUR PROCESS: Garage Epoxy Floors grinds the floor to open the pores

Epoxy Garage Floor Crack Filler – Madison Art Center Design

Epoxy Garage Floor Crack Filler – Madison Art Center Design

The 5 Best Garage Floor Paints (2021 Review)

Metallic Marble Concrete – Epoxy Flooring PCC Columbus, Ohio

Related Posts:

- Epoxy Garage Floor Coating Kit

- Epoxy Floor Coating Tools

- Best Epoxy Garage Floor Product

- Self Leveling Floor Epoxy Home Depot

- How To Apply Epoxy Shield Garage Floor Coating

- Epoxy Garage Floor Paint Reviews

- Metallic Epoxy Floor Designs

- Quikrete Epoxy Garage Floor Coating Kit Reviews

- Metallic Epoxy Flooring System

- Dupont Epoxy Floor Paint

Cracks In Garage Floor Epoxy: A Comprehensive Guide

Garage floor epoxy coatings offer a great way to protect your garage floor from wear and tear. They create a smooth, durable surface that is resistant to staining, water damage, and chemical spills. While epoxy coatings are extremely durable, they are not indestructible. Over time, small cracks can form in the epoxy coating due to age or wear and tear. In this article, we will discuss what causes cracks in garage floor epoxy coatings and how to prevent them from occurring.

What Causes Cracks In Garage Floor Epoxy?

There are several common reasons why cracks may form in garage floor epoxy coatings. The most common cause is the movement of the underlying concrete substrate. Concrete is a porous material that can expand and contract with changes in temperature and humidity levels. This expansion and contraction can cause small hairline cracks to form in the epoxy coating which can eventually widen over time if not addressed properly.

Other causes of cracking in garage floor epoxy include improper preparation of the concrete substrate before coating and inadequate curing time after installation. If the concrete substrate is not properly prepared before application, it can create weak points in the coating which are more prone to cracking. Additionally, if the coating is not given enough time to cure properly after installation, it will be more likely to crack under pressure or stress.

Finally, heavy impacts on the surface of the epoxy can also cause cracking if there is not enough flexibility in the coating material. This type of cracking is often seen on surfaces that have been used for parking cars or storing heavy objects such as bikes or furniture.

How Can I Prevent Cracks In Garage Floor Epoxy?

The best way to prevent cracks in garage floor epoxy is to ensure that it is installed correctly from the start. This means making sure that the concrete substrate is properly prepared before application by grinding or acid etching as needed. It also means allowing the coating to cure completely before exposing it to any heavy use or traffic.

In addition to proper installation, applying a sealant over the top of the garage floor epoxy will help protect it from wear and tear as well as chemical spills and staining. Sealants act as a barrier between the epoxy coating and any contaminants that may come into contact with it, reducing the chance of cracking due to heavy impacts or chemical spills.

Finally, regular maintenance of your garage floor epoxy will also help reduce the chance of cracking over time. This means regularly cleaning any dirt or debris off of the surface and inspecting for any signs of wear or damage. Any minor damage should be repaired promptly before it has a chance to worsen and cause cracking in your epoxy coating.

FAQs About Cracks In Garage Floor Epoxy

Q: Is it normal for my garage floor epoxy to crack over time?

A: Yes, small hairline cracks are normal over time due to changes in temperature and humidity levels as well as wear and tear on the surface of the epoxy coating. However, these should be minor and easily repairable with some basic maintenance tasks such as cleaning and sealing. If you notice large or deep cracks forming in your garage floor epoxy, you should contact A professional for help.

Q: How can I prevent cracks in my garage floor epoxy?

A: The best way to prevent cracks in garage floor epoxy is to ensure that it is installed correctly from the start and given adequate time to cure before use. Additionally, applying a sealant over the top of the epoxy will help protect it from wear and tear as well as chemical spills and staining. Finally, regular maintenance of your garage floor epoxy such as cleaning and inspecting for damage will also help reduce the chance of cracking over time.