Concrete Flooring Precast

Related Images about Concrete Flooring Precast

Strong and dependable Precast Concrete Floors adds value to your home – Flood Precast UK

In addition to a mirror like shine, concrete flooring could be spruced up with embedded patterns, lines, images, grids and other designs. They impart a high-class richness that cannot be achieved by another flooring. With more properties being made in a modern design, concrete polishing floors is actually growing in bounds and leaps. Abrasive pads file down the very best surface area of the concrete.

STRUCTURAL USES OF PRECAST CONCRETE

In order to change the color of the floor, customers might request shake on color hardeners or perhaps penetrating chemical based stains and dyes to alter their greyish concrete to almost any variety of colors. Lately which has altered as a lot more folks are realizing that a polished concrete floor actually looks great. Polished concrete flooring looks a lot more slippery than it's.

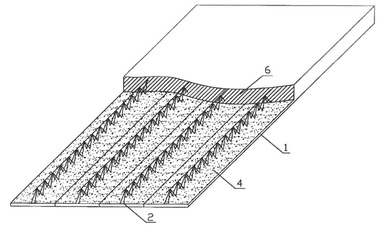

Structural floor with girder-slab – Ballut Blocks – concrete interjoist

This will help leaving the polished concrete floors relatively tidy and at the identical time ensure that the lifespan of the floors is longer since a reduced amount of force used on the floor just means a longer duration for the concrete floor polishing. As the dust is a breeze to pick up with a vacuum, those with any respiratory problems will feel far less irritation.

Precast Concrete Floors in New 2 Story Home – Wright Quarry Products

Precast Concrete Floor Systems Types Of Precast Concrete Floors

Concrete flooring for Commercial Buildings, Precast Concrete UK

WHS 2010: What’s in a Concrete Floor?

Pin on Structural systems

Prefabricated Concrete Staircase Prefab stairs, Home stairs design, Concrete stairs

Colored Concrete Flooring – Concrete Flooring Coating Hyper 2000 Exporter from Chennai

Troubleshooting: Stair Treads and Slopes Concrete Construction Magazine

Upper Floors

Concrete Plant Precast Technology

Applying Polyurea Coatings Concrete Construction Magazine Repair, Garage, Concrete Surfaces

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Concrete Flooring Precast

Concrete flooring precast is a type of concrete slab that is created in a factory setting and then transported to the construction site for installation. Precast concrete flooring offers many advantages over traditional poured-in-place concrete slabs, such as faster installation times and greater strength. It is also much less labor intensive than other types of flooring, making it an economical option for many types of projects. Precast concrete flooring can be used in residential, commercial and industrial applications, providing a durable and attractive solution for any type of project.

What Is Concrete Flooring Precast?

Concrete flooring precast is a type of concrete slab that is manufactured in a factory setting and then delivered to the job site in one piece. The manufacturing process involves mixing cement, aggregate, sand, water and other additives in specialized equipment to create a uniform mix that can be poured into molds. The slabs are then cured in controlled environments until they reach the desired strength before being transported to the jobsite for installation.

Advantages of Concrete Flooring Precast

Precast concrete flooring offers numerous advantages over traditional poured-in-place concrete slabs, including faster installation times, greater strength and durability, and lower labor costs. Compared to traditional poured-in-place slabs, precast concrete slabs can be installed much faster since they require no curing time at the job site. Additionally, precast concrete slabs offer greater strength and durability than other types of flooring, making them suitable for even the heaviest loads. Finally, precast concrete slabs require less labor to install compared to other types of flooring, resulting in cost savings during construction.

Applications of Concrete Flooring Precast

Precast concrete flooring can be used in a variety of applications, including residential, commercial and industrial projects. In residential applications, precast concrete slabs are often used for foundations or basements due to their superior strength and durability. In commercial applications, precast concrete flooring is often used for retail stores or warehouses due to its ability to withstand high traffic areas. Finally, in industrial applications precast concrete slabs are often used for factories or other large scale projects due to their ability to withstand heavy loads.

FAQs About Concrete Flooring Precast

Q: What are the benefits of using precast concrete flooring?

A: The main benefits of using precast concrete flooring include faster installation times, greater strength and durability compared to traditional poured-in-place slabs, and lower labor costs due to less manpower required during installation. Additionally, precast concrete slabs offer enhanced thermal properties since they are not exposed directly to the elements during their manufacturing process, resulting in improved energy efficiency in buildings where they are used.

Q: What types of projects is precast concrete flooring suitable for?

A: Precast concrete flooring is suitable for a variety of projects including residential foundations or basements, commercial retail stores or warehouses, and industrial factories or large scale projects due to its superior strength and durability compared to other types of flooring materials.

Q: How long does it take to install precast concrete flooring?

A: Installing Precast concrete flooring is much faster compared to traditional poured-in-place slabs since there is no curing time required at the job site. The installation process typically takes only a few hours, depending on the size and scope of the project.

What are the benefits of precast concrete flooring?

1. Strength: Precast concrete flooring is strong and durable, making it suitable for a variety of applications. It has excellent compressive strength, load-bearing capacity, and fire resistance.2. Speed of Installation: Precast concrete flooring can be installed quickly and efficiently due to its modular nature and pre-fabricated components. This reduces construction time, labor costs, and site disruption.

3. Low Maintenance: Precast concrete floors require very little maintenance once they are installed, saving you time and money in the long run.

4. Versatility: Precast concrete flooring can be used in a wide variety of settings, from residential homes to commercial buildings. It is also available in a range of colors and finishes to suit any aesthetic preference.

What are the disadvantages of precast concrete flooring?

1. Precast concrete floors are more expensive than other types of flooring.2. Installation of precast concrete floors can be a labor-intensive process.

3. Precast concrete flooring is not suitable for areas subject to frequent and extreme temperature changes, as it may crack or warp over time.

4. Precast concrete floors are not very energy efficient, as they absorb and transfer heat quickly.

5. Precast concrete floors can be difficult to repair if damaged or cracked.