Concrete Floor Slab Section

Related Images about Concrete Floor Slab Section

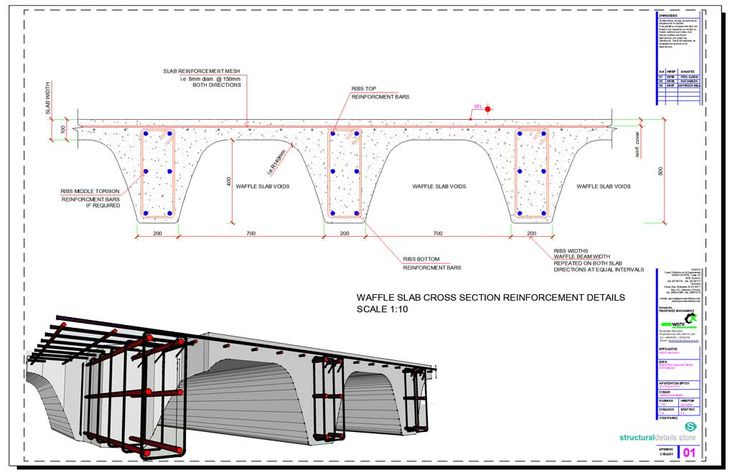

Waffle Slab Cross Section Reinforcement Detail Reinforced concrete, Concrete retaining walls

The primary cause is that these floors are high efficiency flooring options and can last for numerous years. The most difficult part is waiting: When the whole concrete floor is done, you still must hold off parking the car on it for another seventy two hours. However, there are concrete floors which seem plain and gray just love those found in factories and garages.

PDH Quiz – Guide for Concrete Floor and Slab Construction

Polished concrete floors can be the initial step on to creating an allergy-free setting. Polished concrete is turning into a favorite office floor choice due to the longevity of its, easy upkeep, and wide choice of colors and decorative choices. You can also mop it using warm, soapy drinking water, but only utilizing a gentle detergent.

Precast Concrete Floor Slabs Design Manual – Carpet Vidalondon

Once you look at this particular concrete floors as opposed to cork options, it is no surprise that concrete polishing floors are actually increasing in demand, especially in modern homes where minimalism is actually crucial to developing a masterpiece of space. The countless advantages that tag along with concrete polishing renders individuals opt for it, to never mention the economical gains of its.

In Concrete Floor Slab – Carpet Vidalondon

Concrete Slab and Floor base DIYnot Forums

Formwork I Concrete Beam Construction I Shuttering System of Beam I Application on site – YouTube

In Situ Concrete Floor Slab – Carpet Vidalondon

mixed concrete floor texture 0059 – Texturelib

denis Your Decking Ideas Page 267 steel deck, membrane roof, etc Pinterest Steel deck

Defining Concrete Repair: Parking/Plaza Slab Strengthening Concrete Construction Magazine

Concrete Slab Floor Thickness – Carpet Vidalondon

STRUCTURE magazine Creating an Opening in Existing Floors

Concrete floor construction methods and surface characteristics Alphaplan

Revit Structure 2013 Slab Edge Tutorial – YouTube

Related Posts:

- Polished Concrete Floors In Apartments

- Basement Concrete Floor Paint Ideas

- Sanding Concrete Floors For Stain

- How To Seal Concrete Floor Before Carpeting

- Concrete Floor Tile Preparation

- Cold Concrete Floor Solutions

- Stained Concrete Floor Care

- Polished Concrete Floor Bedroom

- Bare Concrete Floor Ideas

- Covering A Concrete Floor

Introduction to Concrete Floor Slab Section

Concrete floor slabs are one of the most common types of construction used in residential and commercial structures. They are typically used to form a level surface for floors, ceilings, and roofs, as well as providing support for walls and other structures. A concrete floor slab is typically made from a combination of concrete, steel reinforcement, and formwork. This article will provide an overview of the different components of a concrete floor slab section and explain how they come together to form the finished product.

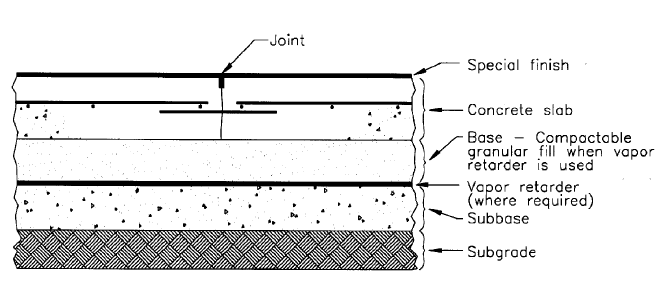

Sub-Grade Preparation

The first step in constructing a concrete floor slab is preparing the sub-grade. The sub-grade is the layer of soil or other material that lies beneath the slab. This layer must be properly prepared in order to ensure that the concrete floor slab is stable and secure. The sub-grade should be cleared of debris and leveled with a compactor or tamper. Additionally, any soft spots or low points should be filled with gravel or sand to create a more solid base. Once the sub-grade has been prepared, it should be covered with geotextile fabric to prevent moisture from seeping into the slab.

Formwork Installation

Once the sub-grade has been prepared, it is time for formwork installation. Formwork is essentially an outline or frame that will hold the wet concrete in place until it hardens. It can be constructed from lumber, metal, or plastic depending on what shape is desired for the finished slab. The formwork must be securely attached to the sub-grade and leveled before concrete can be poured into it. It should also have expansion joints every 10 feet in order to allow for shrinkage during drying and curing.

Concrete Placement

The next step in constructing a concrete floor slab is placing the concrete. Concrete is typically purchased pre-mixed from a supplier and poured into the formwork with either wheelbarrows or pumps. Depending on the size of the area being covered, multiple batches may need to be poured in order to achieve an even thickness throughout the entire slab section. Once all of the concrete has been placed, it should then be spread out with a trowel or screed board in order to level it off before it begins to harden.

Steel Reinforcement

After the concrete has been placed and leveled off, steel reinforcement can then be added if desired. Steel reinforcement bars are typically used to increase strength and stability within a slab section. They are embedded into wet concrete prior to curing, ensuring that they remain firmly in place once hardened. Steel reinforcement bars come in different sizes depending on their intended purpose and can help prevent cracking due to thermal movement or shrinkage during curing.

Curing

Once all of these steps have been completed, it’s time for curing. Curing allows for maximum strength gain by slowly allowing moisture from within the slab to evaporate over time while keeping moisture from outside sources away from it as much as possible. This process usually takes seven days but can take longer depending on weather conditions such as humidity or temperature fluctuations during this period. During curing, water should be sprayed onto the surface at least two times per day in order to keep it moist enough for maximum strength gain without introducing too much moisture which could cause cracking or war Ping.

What are the advantages of a concrete floor slab section?

1. Durability: Concrete floor slabs are very durable and can withstand heavy foot traffic and other wear and tear without cracking or breaking.2. Low Maintenance: Concrete floor slabs require minimal maintenance and are easy to clean with just a quick sweep or mop.

3. Cost-Effective: Installing a concrete floor slab is usually less expensive than other types of flooring materials, making it an economical choice for many homeowners.

4. Versatility: Concrete floor slabs can be designed to fit any space and can be customized with colors, patterns, textures, and more to suit any decorating style.

5. Fire Resistant: Concrete is naturally fire-resistant, making it a safe choice for homes located in areas prone to wildfires or other natural disasters.

What are the disadvantages of a concrete floor slab section?

1. Expensive: Concrete floor slabs are more expensive than other types of flooring materials due to the cost of installation, labor and materials.2. Difficult to repair: Due to their heavy weight and large size, concrete floor slabs can be difficult to repair in the event of damage.

3. Cracking: Concrete is prone to cracking due to its inherent rigidity, which can allow for water penetration and the growth of mold or mildew.

4. Prone to staining: Concrete is also prone to staining from oil, grease and other liquids that can be difficult to remove.

5. Uncomfortable: The concrete surface can be cold and uncomfortable underfoot, requiring additional insulation or carpeting for comfort.