Concrete Floor Membrane

Related Images about Concrete Floor Membrane

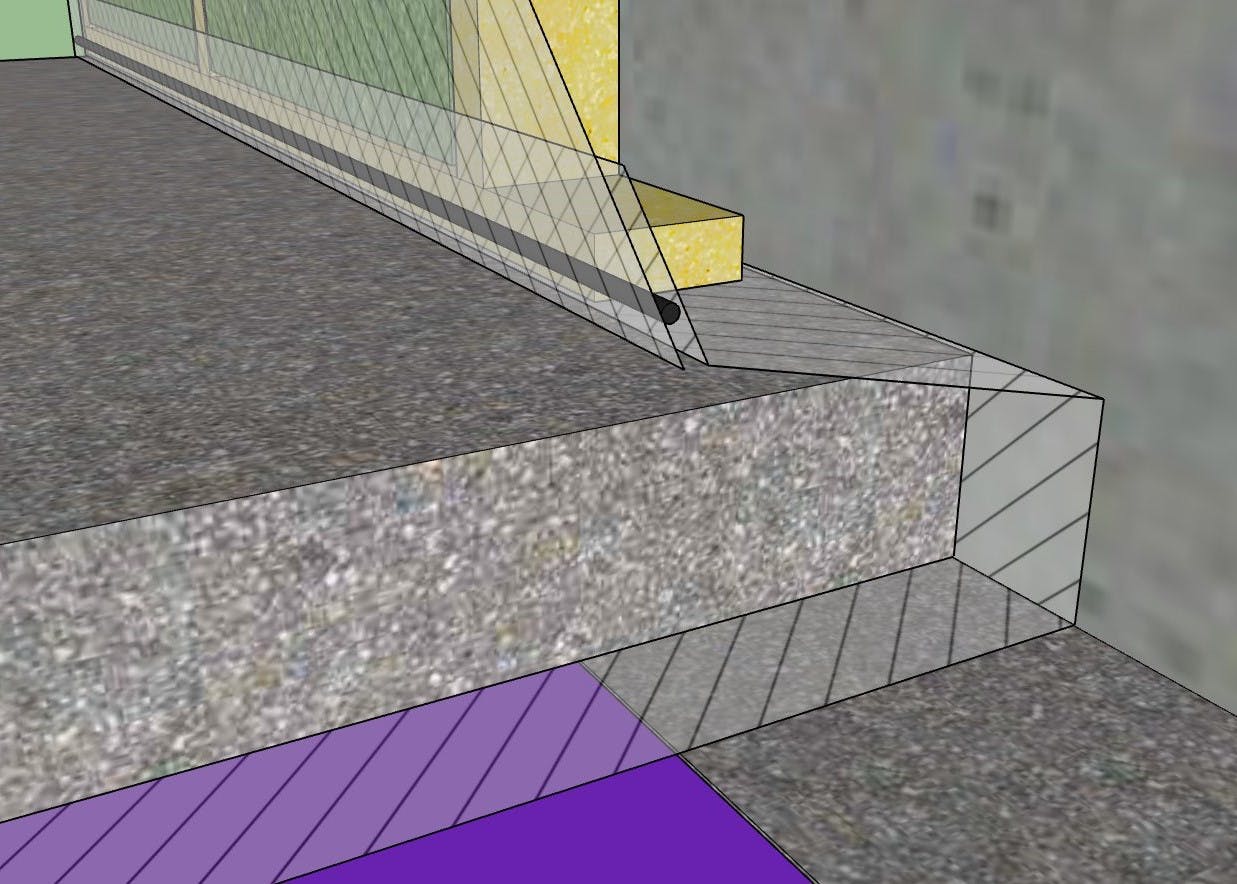

Self Build House Extension Groundwork Concrete Floor Slab

This particular type of system works to stop long lasting degeneration of done concrete floors. Regardless of what might leak on it or even be pulled across it, concrete floors is almost indestructible. When you are thinking you would like to have a lot more choices than merely a shiny surface and color to work into the design objectives of yours, then polished concrete is also the way to go.

A Guide To Steel Decking – What is metal decking?

Staining is probably the most common method put on to concrete floors, acid stains are directly put on to the floor to create strong wealthy colours. Polished concrete flooring comes with a slew of benefits to home builders and renovators. You are able to make several geometric shapes and designs to develop pretty much any patent which you want. The natural color abilities of concrete will accentuate any color scheme.

Waterproofing Membrane for Under Concrete Slab Melbourne – YouTube

Places that have concrete polishing tend to entice a lot more people than those who don't have this concrete sprucing up on the floors. Depending on the apps and the color used doing staining concrete floors, the results can emulate everything from glossy marble improving to tanned lather to all natural stone.

Best Solution to MID in Concrete Concrete Waterproofing Membrane

All-in-One Sound and Thermal Floor Barrier JLC Online

THE IMPORTANCE OF USING DECOUPLING MEMBRANE TO PROTECT YOUR STONE OR TILE FLOOR » Rock & Wood

![]()

Concrete Waterproofing Membrane Application in Barrie, Ontario Eisses Enterprises

Construction of a traditional membrane floor Prothexa-Ker – English

Before & After Archives – Page 2 of 16 Little House On The Corner

concrete membrane removal 3 – Surf Prep

Membranes – Concrete & Paving – Contractor Talk

Basement / Concrete Slab Insulation Job Preparation on Guides

Technocryl Concrete Admixture Twistfix

.jpg?v=b69b7524&mode=h)

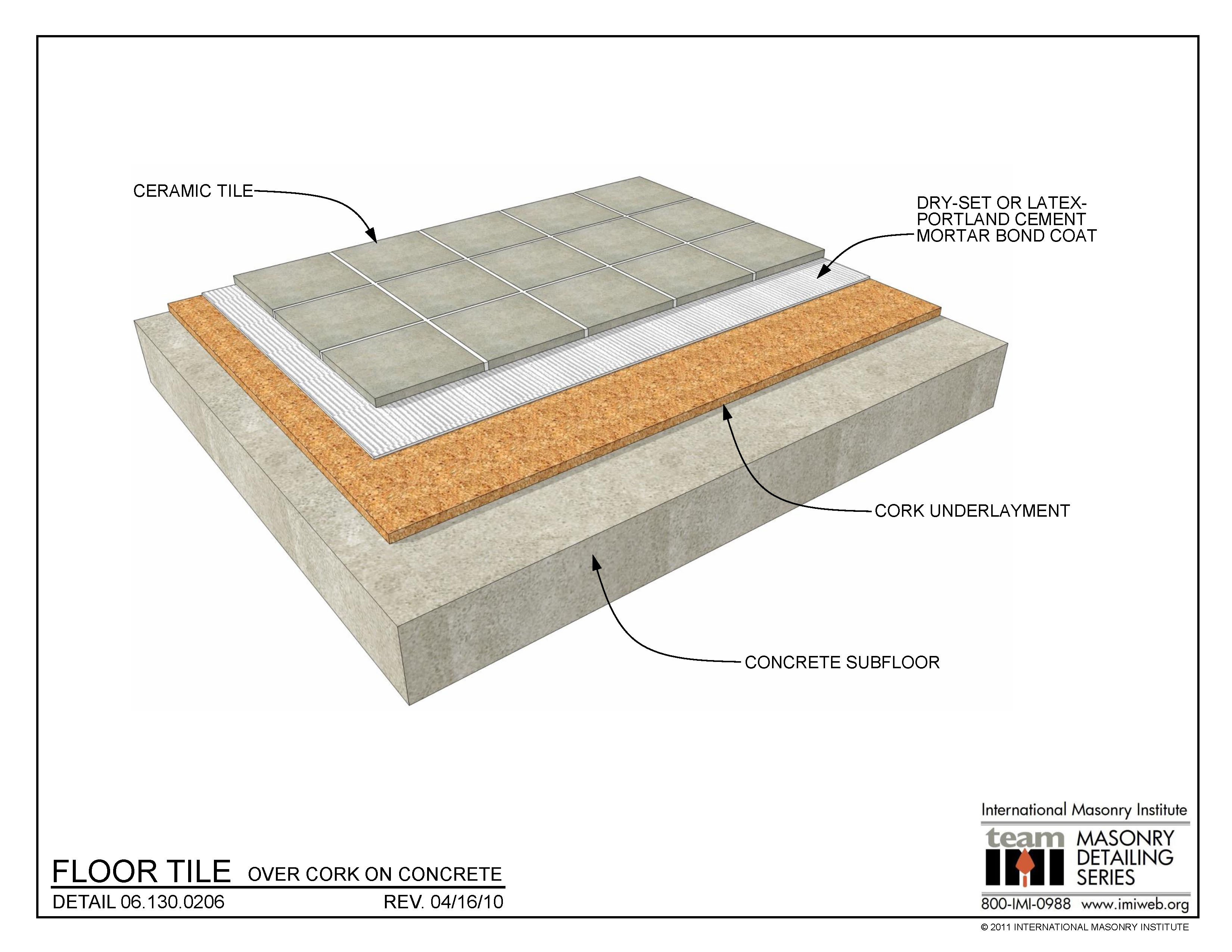

06.130.0206: Floor Tile – Over Cork on Concrete International Masonry Institute

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction

Concrete floor membrane is a type of protective coating used to protect concrete floors from wear and tear. It is designed to provide a layer of protection against water, oil, and other chemical spills as well as providing a wear resistant surface that can withstand heavy foot traffic. It is an effective way to protect concrete surfaces in both residential and commercial applications. In this article, we will discuss the benefits of using concrete floor membrane, how to install it properly, and answer frequently asked questions about this product.

What is Concrete Floor Membrane?

Concrete floor membrane is a type of protective coating that is applied to concrete surfaces in order to provide an extra layer of protection from wear and tear, water, oil, and other chemical spills. The membrane is typically made out of polyurethane or polyethylene plastic and can be applied with a roller or sprayer. The membrane helps to protect the concrete from staining, cracking, chipping, and other damage that can occur over time due to exposure to environmental elements such as rain, snow, and UV radiation. Additionally, it helps to reduce noise levels when walking on the concrete surface.

Benefits of Concrete Floor Membrane

There are many benefits associated with using concrete floor membrane. First, the membrane helps to protect concrete surfaces from wear and tear caused by heavy foot traffic as well as protecting it from spills such as oil and chemicals. Additionally, the membrane can help reduce noise levels when walking on the concrete surface by absorbing some of the sound energy instead of allowing it to reverberate off of the hard surface. Finally, the protective coating also helps to reduce the amount of dust that is created when people walk on the surface which can help improve air quality in indoor spaces such as offices or warehouses.

How To Install Concrete Floor Membrane

Installing a concrete floor membrane is relatively easy if you have some basic knowledge of tools and construction techniques. The first step is to clean the surface thoroughly by removing any dirt or debris that may be present. Next, you will need to apply a primer coat which will help adhere the membrane better to the surface. After the primer has been applied, you can then roll or spray on the membrane itself. Once all the areas have been covered with the membrane you can then allow it to dry for several hours before walking on it or adding any furniture or equipment back onto the floor.

FAQs About Concrete Floor Membranes

Q: What types of surfaces can I use concrete floor membranes on?

A: Concrete floor membranes are designed for use on concrete surfaces only and should not be used on any other type of material such as wood or tile.

Q: How long does it take for a concrete floor membrane to dry?

A: It usually takes several hours for a concrete floor membrane to dry completely depending on environmental conditions such as temperature and humidity levels. Generally speaking, it is best to allow 24-48 hours before walking on it or adding any furniture or equipment back onto the floor.

Q: How often do I need to replace my concrete floor membrane?

A: The frequency with which you need to replace your concrete floor membrane will depend on its usage level as well as environmental factors such as UV radiation levels in your area. Generally speaking, You should expect to replace your membrane every 3-5 years.

What types of concrete floor membranes are available?

1. Moisture Vapor Barriers: Moisture vapor barriers are typically applied prior to the installation of concrete flooring in order to reduce moisture penetration. These membranes are made from a variety of materials, such as polyethylene, EPDM, and PVC.2. Crack Isolation Membranes: Crack isolation membranes are designed to reduce the transmission of cracks from the substrate to the finished concrete flooring. These membranes are typically made from rubberized asphalt or polyethylene and can be applied either over the entire surface or in specific areas where cracking is expected.

3. Anti-Fracture Membranes: Anti-fracture membranes are designed to reduce the potential for delamination or fracturing of the concrete floor due to movement within the substrate below it. These membranes are typically made from either polyethylene or rubberized asphalt and can be applied over the entire surface or in specific areas where movement is expected.

4. Decorative Floor Coatings: Decorative floor coatings provide an aesthetically pleasing finish while helping to protect the underlying concrete floor. These coatings come in a variety of colors and can be applied either as a topcoat over existing concrete or as a stand-alone system.

What are the benefits of using concrete floor membranes?

1. Durability: Concrete floor membranes are incredibly durable and can last for decades even when exposed to heavy foot traffic and other wear and tear.2. Easy to Clean: Concrete floor membranes are easy to clean and maintain, making them ideal for areas that require frequent cleaning such as restaurants, kitchens, and bathrooms.

3. Waterproof: Concrete floor membranes are 100% waterproof, so they can be used in areas prone to flooding or extreme moisture without worry.

4. Cost-effective: Installing a concrete floor membrane is significantly less expensive than installing traditional tile or hardwood floors, making it a great option for budget conscious homeowners.

5. Safety: Concrete floor membranes provide an extra layer of protection against slips and falls, making them ideal for areas with wet conditions such as bathrooms and laundry rooms.