Concrete Floor Leveling Material

Related Images about Concrete Floor Leveling Material

Concrete floor leveling techniques eHow UK

Today's concrete for flooring comes in a broad range of different colors, and it is feasible to include in a number of other elements and different stone to create a polished concrete floor a thing of beauty. Concrete flooring has appeal which is great for all keen on environmentally friendly construction.

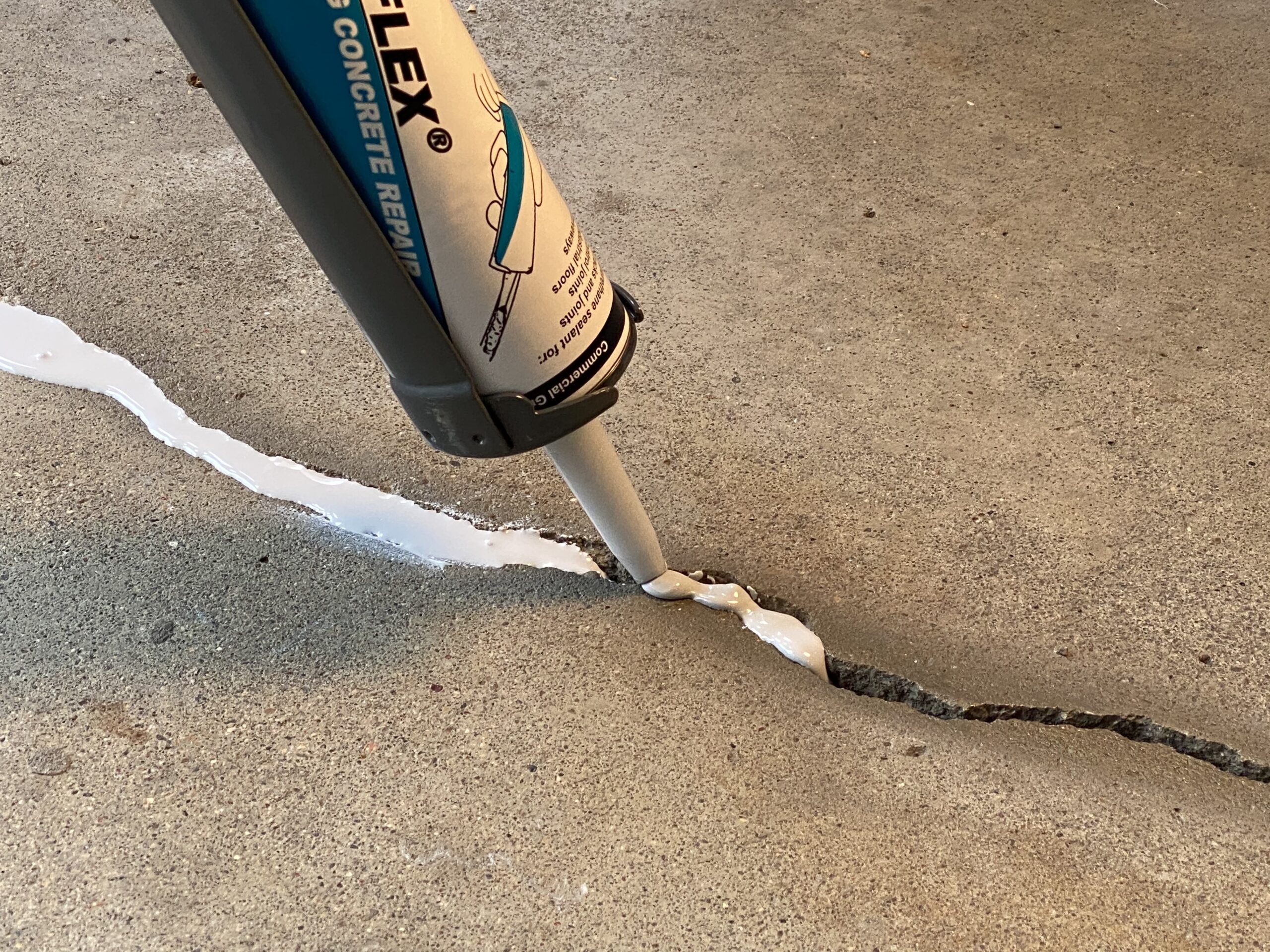

Akonaflex® Self-Leveling Concrete Repair – TCC Materials

This will help leaving the polished concrete floors rather clean and at the identical time ensure that the lifespan of the flooring is longer since less force utilized on the floor simply means an extended length for the concrete floors polishing. As the dust is a snap to pick up with a vacuum, those with any respiratory complications will feel far less irritation.

Can I Use Thinset To Level Concrete Floor – Home Alqu

An extremely tight budget might prompt you to accomplish the concreting task on ones own. A concrete floor also can serve as an excellent base for installation of other flooring treatments as carpets, tiles and hardwood. Concrete flooring is additionally a practical alternative for bathroom and kitchens where they're easily cleaned and therefore are reluctant to water.

Levelling Concrete Floors and How to Level Floors DIY Doctor

Self Leveling Concrete Floor – New York City, New York

Concrete Leveling in Connecticut Stamford Concrete Lifting Contractor

Gypsum Underlayment – Cementitious Underlayment

Werkmaster Titan XT Surface Prep Machine Concrete Construction Magazine Polished Concrete

Bathroom makeover Floor Leveling Pour 1+2 – YouTube

Wood Inlays Add Elegance to Concrete Floor – The Concrete Network

Self-leveling Underlayment

Concrete Flooring Finishing Styles, Colors, and Options – The Concrete Network

Vee-Jay Cement Gypsum Underlayments

Concrete Flooring Finishing Styles, Colors, and Options – The Concrete Network

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Concrete Floor Leveling Material

Concrete floor leveling material is a product designed to even out uneven surfaces in concrete floors. It is used to repair cracks, fill in gaps, and level out bumps and dips in concrete floors. It can also be used to re-level sunken concrete floors, eliminate trip hazards, and help reduce dusting. Concrete floor leveling material is one of the most important tools for ensuring a safe and level surface for walking and working.

Types of Concrete Floor Leveling Material

The type of concrete floor leveling material needed will depend on the type of problem being addressed. Generally speaking, there are three types of concrete floor leveling materials: self-leveling compounds, pourable grouts, and dry-pack mortars. Each type of material has its own unique characteristics that make it best suited for certain applications.

Self-Leveling Compounds

Self-leveling compounds are liquid polymers that are applied directly to the surface of the concrete floor. They are designed to spread evenly over the surface without troweling or other mechanical assistance. Self-leveling compounds have some advantages over traditional methods of concrete repair – they are easy to apply and require no special tools or skills to use. However, they may not be able to level very large areas or fill deep holes.

Pourable Grouts

Pourable grouts are similar to self-leveling compounds but have a thicker consistency which allows them to fill deeper holes and larger areas without requiring additional troweling or mechanical assistance. These grouts can also be used to fill cracks and other imperfections in concrete floors. However, they tend to be more expensive than self-leveling products and may require more labor intensive preparation prior to use.

Dry-Pack Mortars

Dry-pack mortars are composed of dry cementitious materials mixed with a water based adhesive solution. They are usually applied by hand with a trowel and then allowed to set before being leveled off with a straight edge tool such as a long board or screed bar. Dry-pack mortars can be used for filling large voids, filling cracks, leveling slabs, and repairing steps in concrete surfaces. However, they require more skill and experience than self-leveling compounds or pourable grouts so they may not be suitable for all applications.

FAQs About Concrete Floor Leveling Material

Q: What is the best way to level an uneven concrete floor?

A: The best way to level an uneven concrete floor depends on the size and depth of the area that needs repair. For small areas where only minor adjustments need to be made, self-leveling compounds can be used; while for larger areas or deep holes, dry-pack mortars may be more appropriate. For very large areas or deep holes pouring grout may be necessary as well as a troweling step after installation in order to create a smooth finish on the surface of the floor.

Q: How long does it take for concrete floor leveling material to set?

A: The amount of time it takes for concrete floor leveling material to set will vary depending on the type of product being used as well as environmental conditions such as temperature and humidity levels. Generally speaking, Self-leveling compounds and pourable grouts will take approximately 4-6 hours to set, while dry-pack mortars may take up to 24 hours to fully cure.

What is the best concrete floor leveling material?

The best concrete floor leveling material will depend on the specific application and desired outcome. Some popular options include self-leveling concrete, a cementitious topping, or a polyurethane-based self-leveling compound. All three of these materials can be used to level out uneven floors, but each has its own pros and cons. It’s best to consult a professional for guidance in choosing the best option for your project.What is the difference between concrete floor leveling and concrete floor resurfacing?

Concrete floor leveling is the process of raising and smoothing an uneven concrete surface, while concrete floor resurfacing involves applying a new layer of concrete to the existing surface. Floor leveling typically requires grinding or using a self-leveling compound, while resurfacing typically requires applying a concrete overlay. Both processes can improve the appearance and durability of a concrete floor, but they are different processes.What are the advantages of concrete floor leveling?

1. Increased durability: Concrete floor leveling increases the durability of your concrete floor, as it ensures that your floor is even and level and will not be damaged by shifting or settling.2. Improved insulation: Concrete floor leveling helps improve insulation by sealing up any air gaps that may exist in your concrete floor. This helps to keep your home warm in the winter and cool in the summer.

3. Easier cleaning: An even, level concrete floor is much easier to clean than one that is uneven or has dips and bumps. This can help you save time when it comes to cleaning your floor, as you won’t have to pay as much attention to detail when sweeping and mopping.

4. Enhanced aesthetics: A leveled concrete floor can add a polished look to any room or space, making it look more attractive than an uneven one. It can also help make a space feel larger, as the even surface will create fewer shadows from light sources.