Concrete Floor Joint Filler

Related Images about Concrete Floor Joint Filler

Concrete Floor Joint Filler – Repair Products – Turning Point Supply

Polished concrete flooring is a beautiful style alternative for the people seeking a distinctive high gloss look to their floors. Decorative concrete floor is under your feet nowadays anywhere you go. With time, it may seem to be evident that the shine or perhaps glitter on the concrete floors polishing is actually reducing. Concrete floors are much sturdier as well as maintenance free.

Filling expansion joints by GapArmour.com – YouTube

A polished concrete floor doesn't need frequent cleaning, meaning that you can clear them alternatively or whenever you are absolutely free. Concrete is quite long-lasting and never ever needs to be replaced although you could have to touch up the finish that's a pretty easy and inexpensive job. Along with these benefits, one of the major advantages of concrete floors is its pricing.

Pourable Concrete Crack Filler – from Sporty’s Tool Shop

Sometimes grease, other things or oil are able to stain concrete floor. The one thing that will scrape a concrete flooring is a jackhammer. They are okay to be reinforced so as to be powerful enough to hold the unwanted weight of a truck. Dying is not the sole style option for polished concrete flooring. The dust as well as dirt doesn't follow the floor, like it can with carpet.

Semi-rigid joint filler Concrete Construction Magazine Concrete Slabs and Floors, Metzger/McGuire

Concrete Expansion Joint Filler Products and Repair Systems

Sealant JVS Building Services

Concrete Joint Filler – Expansion Joint Filler – AllStar Concrete Coatings

Joint Filling – Concrete Floor Specialists Commercial And Residential Flooring, Concrete Services

Concrete Slab Expansion Joint Material With Sgs Approved – Buy Concrete Slab Expansion Joint

Joint Filling – Concrete Floor Specialists Commercial And Residential Flooring, Concrete Services

How to Repair Flaking & Cracking Warehouse Flooring

DIY Repair Sidewalk Expansion Joints – YouTube

Legacy Industrial’s Blog Site: Fill joints in your garage concrete floor slab before epoxy coating.

Concrete Expansion Joints (Filler Material) – Easy To Handle And Install – W. R. Meadows

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Concrete Floor Joint Filler

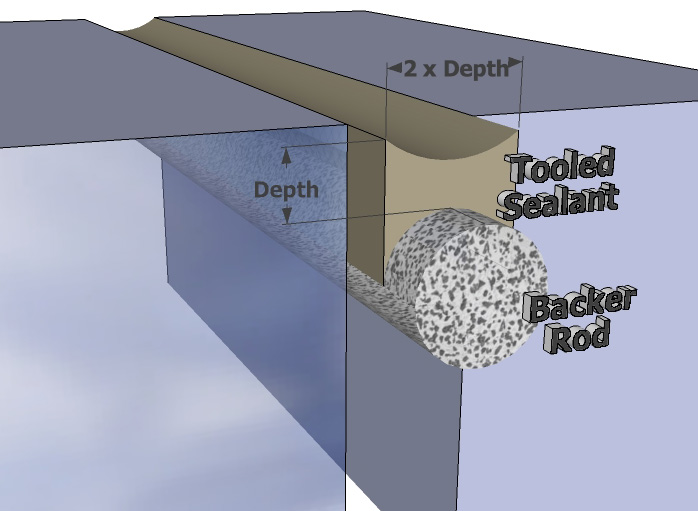

Concrete floor joint filler is a necessary part of any concrete flooring installation. It helps to provide a smooth, even surface that is free from cracks and other imperfections. It also helps to reduce the amount of noise that is created when walking on the concrete floor, and it helps to prevent dirt, dust, and debris from settling in between the joints. The installation of concrete floor joint filler is an important step in ensuring that your concrete floors will last for many years to come.

Types of Concrete Floor Joint Filler

There are a variety of different types of concrete floor joint filler available on the market today. These include epoxy-based products, polyurethane-based products, and self-leveling products. Each type of product has its own unique benefits and characteristics. For example, epoxy-based products tend to be more durable and long-lasting than polyurethane-based products. Self-leveling products are generally easier to install but can be more expensive.

Benefits of Installing Concrete Floor Joint Filler

Installing concrete floor joint filler provides many benefits to homeowners and businesses alike. It helps to create a smoother walking surface, reducing the amount of noise created when people walk across the surface. It also helps to reduce or eliminate dirt, dust, and debris from settling in between the joints. Additionally, it prevents cracks from forming in the surface, which can lead to costly repairs if left unchecked. Finally, it helps to make the entire surface look more aesthetically pleasing as well as making it easier to clean and maintain over time.

Preparation Before Installing Concrete Floor Joint Filler

Before installing concrete floor joint filler, it is important that you take some time to properly prepare the area where you plan on applying it. This includes cleaning the surface thoroughly with a broom or vacuum cleaner, removing any dirt or debris that may be present in the joint area. Additionally, you should ensure that any cracks or imperfections in the surface are repaired before applying the joint filler. This will help ensure optimal results when installing the joint filler itself.

Application Process for Concrete Floor Joint Filler

Once you have properly prepared the area for installation, you can then begin applying your chosen concrete floor joint filler product. Depending on which type of product you choose to use, this process will vary slightly. Generally speaking however, you should apply a thin layer of product into each joint across the entire surface using either a trowel or putty knife for smaller areas. Once applied evenly across all joints, allow sufficient time for drying before walking on the surface or beginning any additional repairs or renovations in the area.

FAQs about Concrete Floor Joint Filler

Q1: How long does it take for concrete floor joint filler to dry?

A1: The exact time required for concrete floor joint filler to dry will depend on several factors such as temperature and humidity levels in your area as well as which type of product you choose to use. Generally speaking however, most products require anywhere from 8-12 hours before they are fully cured and ready for use.

Q2: Does concrete floor joint filler need to be sealed?

A2: While some Types of joint filler may not need to be sealed, it is generally recommended that you seal your concrete floor joint filler in order to help protect it from moisture and stains. Sealing the joint filler will also help extend its life and make it easier to clean and maintain over time.