Concrete Floor Grinding And Polishing Equipment

Related Images about Concrete Floor Grinding And Polishing Equipment

concrete polishing machine rental, concrete grinding machines for sale, how to grind a concrete

In order to increase the long life of the floor, people pores ought to be sealed. Those with allergies or asthma will like experiencing polished concrete. An excellent bristle push broom or street broom is actually strong enough to stand approximately the hard concrete floor, but efficient enough to provide a highly effective cleaning.

Concrete Floor Grinding Polishing Machines

Sealants, for example a polymer floor seal, offer positives that are numerous to interior and exterior floors and are a very good addition to a concrete floors maintenance program. Caring for your decorative concrete floors isn't very different than the normal upkeep you perform in virtually any aspect of your home.

Grinding & Polishing Our Concrete Floor – YouTube

It is crucial to have flooring that is not just comfortable, but helps you lead a quality way of life. Synthetic staining can develop can tell is in patents on your concrete floor and can be worn in new or old concrete slabs. Polished concrete floors are the best flooring options for homeowners and designers due to their versatility, beautiful looks & long lasting features.

Kinty 230v Concrete Grinder Floor Refurbished Clean Grinding Machine1900w Electric Concrete

Why Finding the Right Grinder can Make a Difference Concrete Decor

Concrete floor polishing machine, concrete grinder and polisher – YouTube

High Speed Grinding Equipment Concrete Floor Polishing Machine – Buy Floor Polishing Machine

How to Polish Concrete Countertops Concrete Exchange

Concrete Floor Grinding And Polisher – Buy Concrete Floor Grinder,Planetary Polishing Floor

Chicago Decorative Concrete Equipment Tools and Rentals

surface grinding and polishing machine

Diamond Tooling Tips – The Concrete Network

Concrete Grind And Seal – The Kings Of Concrete Polishing

Granite floors grinding and polishing with Klindex Levighetor – YouTube

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Concrete Floor Grinding and Polishing Equipment

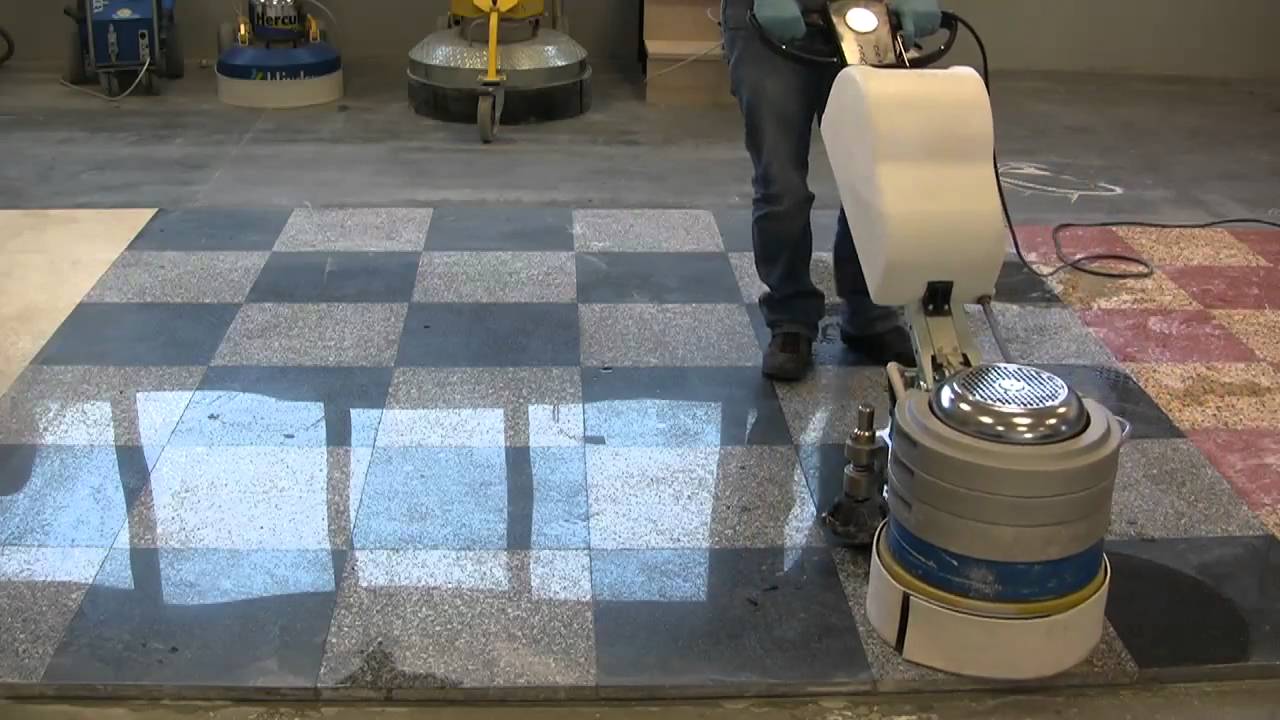

Concrete floor grinding and polishing equipment are used to transform worn and stained concrete floors into a beautiful, durable, and long-lasting surface. This type of equipment is designed to grind, polish, and resurface concrete floors with ease. It is an important part of concrete floor maintenance and finishing projects. The right type of grinding and polishing equipment can make all the difference in the outcome of any concrete floor project.

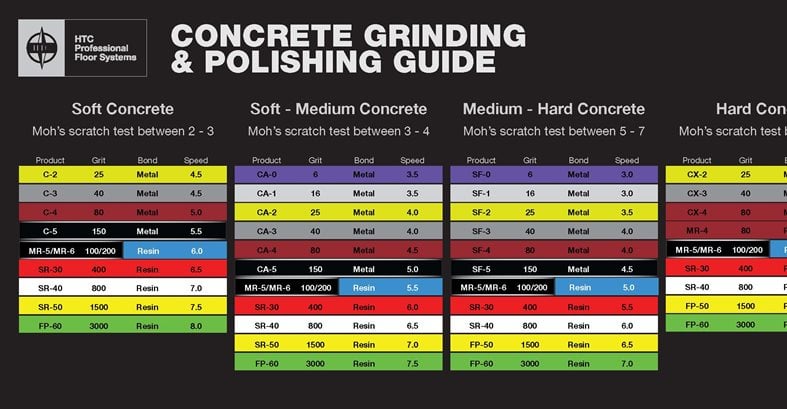

Grinding and Polishing Process

The grinding and polishing process starts with the removal of existing coatings such as paint, sealers, or adhesives. This step is followed by grinding down the uneven surfaces and ridges of the concrete floor to create a smooth and even surface. After this step is completed, the concrete floors are then polished with diamond abrasive pads to create a glossy finish. Depending on the desired finish level, additional steps such as sealing or coating may be applied to protect the newly polished surface from wear and tear.

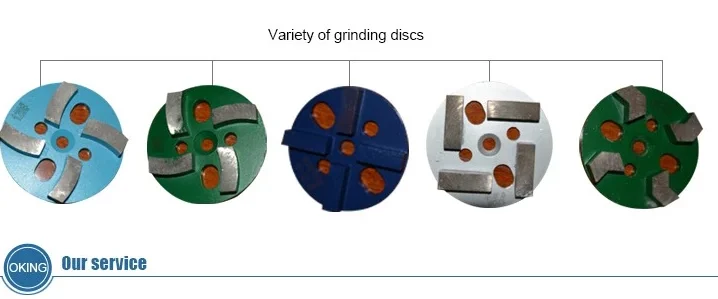

Types of Concrete Floor Grinding and Polishing Equipment

There are many types of concrete floor grinding and polishing equipment available to suit different needs. The most common types of equipment include walk-behind grinders, ride-on grinders, planetary grinders, edge grinders, hand grinders, vacuum systems, burnishers, scarifiers, dust collectors, propane buffers, diamond tooling systems, dust extractors, dust control systems, wet vacuums, etc. Depending on the size of the project or area being worked on, one or more pieces of equipment may be used in combination for maximum efficiency.

Benefits of Concrete Floor Grinding and Polishing Equipment

Using concrete floor grinding and polishing equipment has several benefits for both residential and commercial applications. It can help remove stubborn stains and scratches from surfaces as well as restore any damaged areas that may have occurred over time. Additionally, it helps protect surfaces from further damage by providing a durable finish that won’t peel or fade over time. Furthermore, it helps reduce costs since many pieces of equipment are designed for multiple uses; these include grinding large surfaces as well as smaller areas around edges or corners. Finally, it provides an aesthetically pleasing finish that can enhance any space’s overall look while also making it easier to maintain in the long run.

FAQs about Concrete Floor Grinding And Polishing Equipment

Q: What is concrete floor grinding?

A: Concrete floor grinding is a process used to prepare a concrete surface by removing old layers of paint or sealants. It involves using specialized tools like walk-behind grinders or ride-on grinders equipped with diamond abrasive pads that slowly grind away at the top layer of material until a smooth surface is achieved.

Q: How long does it take to grind a concrete floor?

A: The length of time required for a successful concrete floor grinding project depends on several factors such as the size of the area being worked on and its condition prior to starting work. Generally speaking though, most projects can be completed in 1-2 days depending on their scope.

Q: What type of grinder should I use for my project?

A: The type of Grinder you use will depend on the size of your project and the type of surface that needs to be worked on. For larger projects, a walk-behind grinder or ride-on grinder is usually the best choice, while for smaller areas a handheld grinder may be more suitable.