Concrete Floor Electrical Box

Related Images about Concrete Floor Electrical Box

Concrete floor boxes in slab on grade – Floor Box Systems

Remember concrete flooring can be covered with a number of materials including epoxy, an attractive durable finish which might be used anywhere in the home. Concrete office flooring is a greenish choice which usually outlasts other floor varieties like carpet, tile, wood, and linoleum.

Arlington Recessed Outlet Floor Box for Concrete Floor boxes, Flooring, Concrete

Many people cover the concrete floor of theirs with floor coverings but one can’t argue with the longevity as well as unpolluted potential of concrete. Water based paints are generally not a terrific idea with regards to concrete flooring, as they usually do not adhere to the surface very nicely.

Floor Box Outlet – Concrete Floor Boxes – Tagged “1100”

There are several areas where the concrete polishing is being employed and a lot of folks are likely to prefer the polished concrete floor because of all the benefits which accrue to the proprietors of such floors. For that reason it will come as no surprise if you walk into a household that has concrete floor polishing that there aren’t any cracks, destroys or leaks on the outside.

Electrical floor boxes – Four gang Shallow floor box FBS

Two gang floor box for hardwood floor Floor Box Systems™

Patent US7795544 – Recessed electrical outlet box for concrete floors – Google Patentsuche

Precast Electrical Box – Locke Solutions ICF Concrete Additives

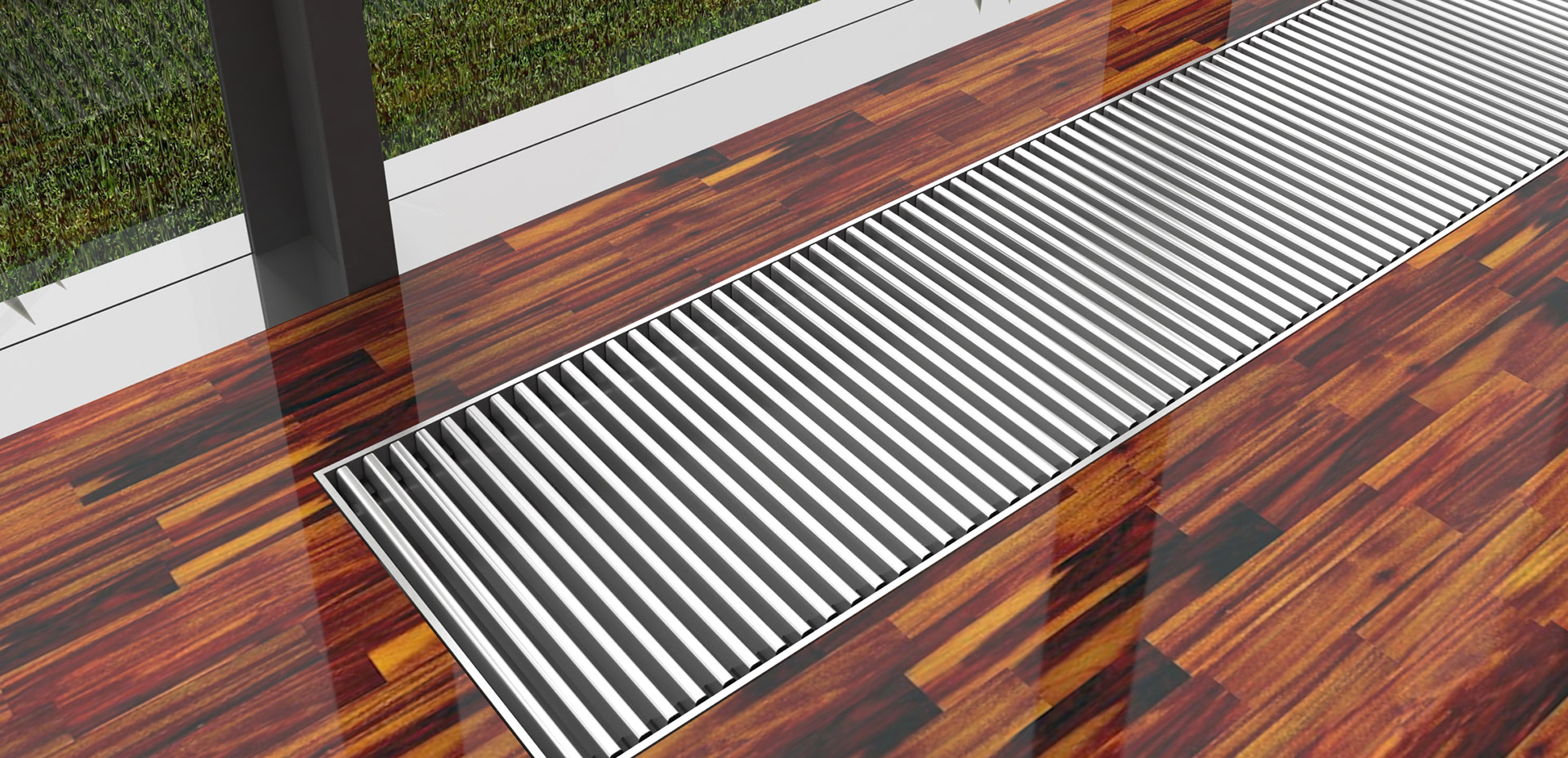

Hydronic Trench Convectors Geelong – Heating Plus

Precast Concrete Products

How to Install an Outlet Box in Concrete Block

West Auctions – Auction: Secured Creditor Liquidation of Roadway Engineering Works Inc ITEM

FBS – Floor Box Systems: Electricity, Smart buildings, Access control – ArchiExpo

Two gang floor box Hardwood, raised wood floors FBS

black box floor plan 150m2

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Concrete floor electrical boxes are essential components in electrical installations that require power and data outlets to be installed directly into a concrete floor. These boxes provide a safe and secure housing for electrical connections while also ensuring a level surface for walking or driving over. In this article, we will explore the various types of concrete floor electrical boxes, their installation process, benefits, and common FAQs associated with them.

Types of Concrete Floor Electrical Boxes

There are several types of concrete floor electrical boxes available in the market, each designed to meet specific installation requirements. Some of the most common types include:

1. Flush-Mounted Electrical Boxes: These boxes are installed flush with the concrete floor surface, providing a seamless and aesthetic finish. They are typically used in areas where the electrical outlets need to be discreetly hidden.

2. Adjustable Floor Boxes: These boxes come with adjustable height settings, allowing them to accommodate different floor thicknesses. They are ideal for installations where the concrete floor depth may vary.

3. Pop-Up Floor Boxes: These boxes feature a retractable cover that pops up when needed, providing easy access to electrical outlets. They are commonly used in areas with limited space or where access to power outlets needs to be convenient.

4. Round Floor Boxes: These circular-shaped boxes are designed for installations that require a round outlet configuration. They provide a clean and modern look to the concrete floor while accommodating multiple power and data connections.

Installation Process of Concrete Floor Electrical Boxes

The installation process of concrete floor electrical boxes involves several steps to ensure a secure and reliable connection. Here is a detailed overview of how these boxes are typically installed:

1. Planning: Before installing the electrical box, it is essential to plan the placement of the outlets based on the specific requirements of the installation area. This includes determining the number of outlets needed, their location, and any special features required.

2. Marking: Once the outlet locations have been determined, mark the positions on the concrete floor using a pencil or chalk line. This will serve as a guide for cutting out the opening for the electrical box.

3. Cutting: Use a concrete saw or grinder to cut out the marked openings on the concrete floor. Take care to follow precise measurements to ensure a snug fit for the electrical box.

4. Installation: Place the concrete floor electrical box into the cut-out opening, ensuring that it sits flush with the surface of the floor. Secure the box in place using appropriate fasteners or adhesive as recommended by the manufacturer.

5. Wiring: Connect the electrical wiring to the terminals inside the box, following all safety guidelines and local building codes. Make sure to test all connections before closing up the box.

6. Finishing: Once the wiring is complete and tested, install any necessary covers or plates over the electrical box to protect it from dust, debris, and moisture.

Benefits of Concrete Floor Electrical Boxes

Concrete floor electrical boxes offer several advantages that make them an ideal choice for various applications:

1. Durability: Concrete floor electrical boxes are built to withstand heavy loads and foot traffic, making them highly durable and long-lasting.

2. Safety: By securely housing electrical connections within a sturdy enclosure, these boxes reduce the risk of electric shocks or shorts caused by exposure to moisture or debris.

3. Aesthetics: With their sleek and discreet design, concrete floor electrical boxes provide a clean and professional finish that complements any interior décor.

4. Accessibility: Pop-up and adjustable floor boxes offer convenient access to power outlets without compromising on space Or design. They can easily be hidden when not in use, providing a clutter-free environment.

5. Flexibility: Concrete floor electrical boxes come in a variety of configurations to accommodate different power and data connections, giving users the flexibility to customize their electrical setup as needed.

6. Versatility: These boxes can be installed in a wide range of environments, including residential homes, commercial buildings, offices, and outdoor spaces, making them a versatile solution for various applications.

Overall, concrete floor electrical boxes offer a reliable and efficient way to provide power and data connections in concrete floors while maintaining the aesthetics and functionality of the space. Their durability, safety features, and accessibility make them a popular choice for modern electrical installations. 7. Maintenance: Regular maintenance of concrete floor electrical boxes is essential to ensure their continued functionality and safety. Inspect the boxes periodically for any signs of wear or damage, and promptly address any issues to prevent potential hazards.

8. Compatibility: When choosing concrete floor electrical boxes, make sure they are compatible with the specific requirements of your electrical system, including voltage, amperage, and wiring configurations. Consult with a professional electrician if you are unsure about which box to use.

9. Regulations: It is important to comply with all local building codes and regulations when installing concrete floor electrical boxes. Failure to do so could result in fines or safety hazards. Always hire a licensed electrician to assist with the installation process.

10. Upgrades: As technology advances, consider upgrading your concrete floor electrical boxes to accommodate new devices or equipment that may require additional power outlets or data connections. Stay informed about the latest advancements in electrical systems to ensure your setup remains up-to-date and efficient.

By following these guidelines and considering the benefits of concrete floor electrical boxes, you can create a safe and functional electrical system that meets your needs while enhancing the overall aesthetics of your space. Remember to prioritize safety and quality when installing and maintaining electrical components to prevent accidents and ensure long-term reliability.