Concrete Floor Construction Types

Related Images about Concrete Floor Construction Types

Block Research Group

Concrete floors have a tendency to get cold especially on colder temperature so right before the cement combination is poured on the floor, radiant floor pipes or adaptable tubing are actually first laid on the surface. When you're searching for a flooring solution for your house project which combines elegance and simplicity, then you actually will want to explore polished concrete floors.

Maison 7" Engineered Hickory Hardwood Flooring in Champagne Wood floors wide plank, Flooring

In certain instances, almost all that will be needed is a basic rebuffing of the floor surfaces with a little polishing compound. Remember it's important to use concrete floor sealers to help you protect the surface area. It is real that one requires quite some basic strategy of looking soon after these concrete floors but there are particular facts about maintenance that have to be kept as the primary goal.

Tips for Installing Concrete Pier Footings – Extreme How To Concrete footings, Deck footings

Nonetheless, visual appeal as well as the performance of concrete might be hampered by the practical safety aspects of its, especially for young children. When used in basements, having bare concrete floors is a far more hygienic alternative from moldy carpets and rugs.

2nd storey load concrete floor – Google Search structure Pinterest Concrete floor

Garage Build Part 4 – Building forms for our concrete foundation – YouTube

deck pier footing design – Google Search Deck footings, Building a deck, Concrete deck

Define Floor In Construction Review Home Decor

ගෘහ නිර්මාණ සැලසුම් ශිල්පය: සැලැබ් එකකට යන අමුද්රව්ය ප්රමාණය හා වියදම

Continuous frames – Steelconstruction.info

Segregation Structural engineering, Civil engineering, Engineering

Solid Timber Floor On Concrete – Carpet Vidalondon

Concrete Log Siding Features and Benefits EverLog Systems

Technical Details My CMS

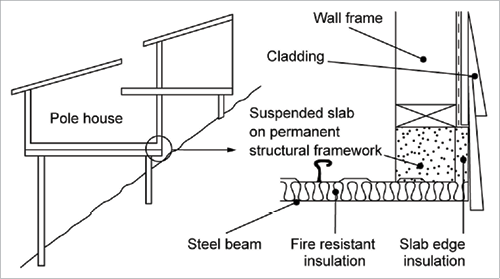

Patent US20020078646 – Suspended concrete flooring system and method – Google Patents

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Concrete Floor Construction Types

Concrete floors are a popular choice for many commercial and residential applications, due to their durability and low-maintenance. As with any concrete project, there are a variety of construction types to choose from when building a concrete floor. Each type has its own advantages and disadvantages, so it is important to consider the specific needs of your project before deciding which method is best for you. In this article, we will discuss the various types of concrete floor construction and provide information to help you determine which one is right for your needs.

Floating Floors

A floating floor is a type of concrete floor that is not attached to the underlying structure or subfloor. Instead, it is laid on top of an existing surface, such as a wood or vinyl subfloor, and secured with adhesives or mechanical fasteners. Floating floors are often used in residential and commercial applications where the existing subfloor cannot be removed or replaced due to cost or other constraints. They are also commonly used in areas where moisture may be present, such as bathrooms or basements. The main advantage of a floating floor is that it is less time consuming and costly than other methods of installation. However, since the floor is not attached directly to the underlying structure, it can be more prone to movement over time, which can lead to cracking or warping.

Mortar Bed Floors

A mortar bed floor is a type of concrete floor that is created by pouring a thin layer of mortar over an existing subfloor. This method is often used in areas where an existing subfloor cannot be removed or replaced, such as in bathrooms and basements. The main advantage of this method is that it allows for greater flexibility in terms of design and finish options than other types of installation. Additionally, since the mortar bed provides additional strength and stability, it can help reduce the risk of cracking or warping over time. The main disadvantage of this method is that it requires more labor-intensive preparation than other methods, as any imperfections in the underlying surface must be filled before the mortar can be applied.

Self-Leveling Floors

Self-leveling floors are a type of concrete floor that uses self-leveling compounds to create a smooth, uniform surface. This type of installation is often used in areas where an existing subfloor cannot be removed or replaced due to cost or other constraints. It also provides an easy way to level out uneven surfaces without having to use large amounts of additional material for filling imperfections. The main advantage of this method is that it produces a smooth surface with minimal effort on the part of the installer; however, since self-leveling compounds are more expensive than traditional concrete mixes, this type of installation may not be suitable for all budgets. Additionally, self-leveling floors require careful preparation prior to installation in order to ensure proper adhesion and performance over time.

Cementitious Urethane Floors

Cementitious urethane floors are a type of concrete floor created by applying cementitious urethane coating over an existing substrate. This type of installation can provide superior performance in areas where heavy wear and tear may occur, such as warehouses or industrial facilities. The main advantage of this method is that it produces a waterproof surface with excellent resistance to chemicals and abrasive materials; however, due to its high Cost, it may not be suitable for all budgets. Additionally, cementitious urethane floors require careful preparation prior to installation in order to ensure proper adhesion and performance over time.

What are the different types of concrete flooring?

1. Polished Concrete: Polished concrete is a popular choice for modern and industrial-style homes. It is a process that takes a basic concrete slab and grinds it down to reveal the natural aggregate in the mix. The surface is then sealed with a protective coating for a glossy finish.2. Stained Concrete: Staining concrete floors is another popular option for creating unique surfaces. It involves applying an acid or water-based stain to the concrete, which reacts with the minerals in the mix to create beautiful colored patterns.

3. Epoxy Coating: Epoxy coatings are often applied over existing concrete to protect it from wear and tear, as well as give it a more attractive finish. These coatings can be clear or tinted, and they provide a smooth, hard surface that’s resistant to staining and easy to clean.

4. Overlays: Concrete overlays are thin layers of cement-based material that are applied over existing concrete slabs to give them a new look and feel. These materials can be troweled on like standard concrete, stamped with patterns, and even dyed to match any color palette you desire.

5. Terrazzo Flooring: Terrazzo flooring is composed of chips of marble, quartz, or granite set into a cement base and then polished smooth. It’s a great way to bring an elegant look to any room and can be used indoors or out due to its durability and weather resistance.