Concrete Floor Blasting

Related Images about Concrete Floor Blasting

Blasting concrete floor BLASTEK Mobile Blast Cleaning

Concrete floors tend to get cold especially on colder temperature so right before the cement mixture is poured on the flooring, sparkling floor pipes or flexible tubing are for starters laid on the surface. When you are searching for a flooring alternative for your house project which combines simplicity and elegance, then you certainly will need to explore polished concrete floors.

Car Park Shot Blasting. Concrete Floor Preparation UK

The polished floors are actually among the best techniques to maintain the right flooring while in trying to keep with' green' observance simply because concrete flooring does not call for inclusion of other raw materials or perhaps substances, which would otherwise put a strain on the environment. Alternatively, concrete pulls the heating from the sun in the winter months, for this reason your flooring remains warm.

WOW! Look at this New Blastrac 1-8DM Shot Blaster CoatingsPro Magazine

more and More homeowners as well as designers are actually developing warehouses and basements with concrete due to the appearance, the organic beauty, the easiness in maintenance and also the warmth it brings to a place. The method is very simple to apply with state-of-the-art technological innovation. In case you walk into a put that has polished concrete flooring, you will realize immediately that the dojo is rather similar to marble.

Shot Blasting Concrete Shot Blast Inc

Shot Blasting to prepare concrete floor – StrongBond

Concrete Cleaning Inc. – Steel Shot Blasting, Floor Surface Preparation, Concrete Polishing

Shot Blasting – Crystal Soda Blast

Concrete & Masonry Repair Sand Blasting Scarifying

Concrete Surface Preparation Pennsylvania Concrete Resurfacing New Jersey Delaware Maryland

Shot Blasting – Concrete Floor Specialists Commercial And Residential Flooring, Concrete Services

Surface Prep Guidelines – Coatings For Industry, Inc

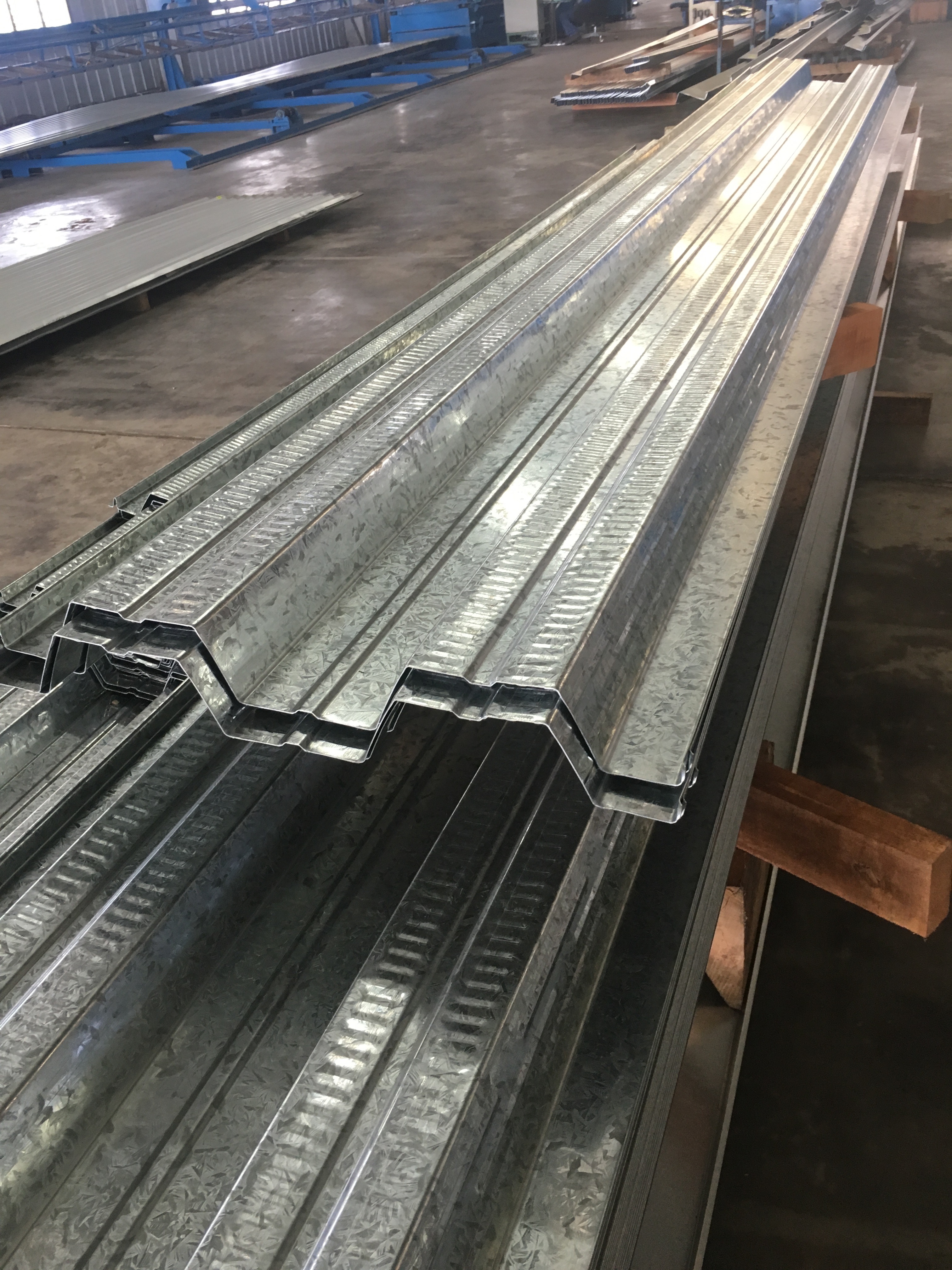

Composite Floor Decking – Roof Systems

Concrete Flooring Finishing Styles, Colors, and Options – The Concrete Network

What is The Best Epoxy Paint to Refinish a Garage Floor? Metrocrete Concrete Flooring Contractors

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Concrete Floor Blasting

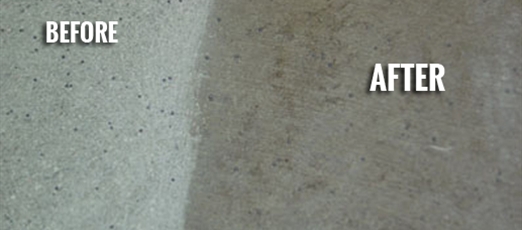

Concrete floor blasting is a process that utilizes high-pressure air and abrasive materials to clean, smooth and resurface concrete floors. It is a popular method for renovating or restoring concrete floors that have become dull, stained or otherwise damaged over time. The process involves using a special type of machine called a blast pot, which is filled with an abrasive material such as recycled glass beads, aluminum oxide or steel shot. The blast pot is then connected to a compressor and the material is forced through a nozzle at high pressure against the surface of the concrete floor. The abrasive material breaks down the surface of the concrete, leaving it smooth and free from dirt, dust and other debris. This process can be used to prepare concrete surfaces for painting, staining or sealing, as well as restoring old or worn-out surfaces.

Benefits of Concrete Floor Blasting

Concrete floor blasting offers many benefits compared to other methods of cleaning and resurfacing concrete floors. It is fast and efficient, able to cover large areas quickly without leaving behind any residue. It also removes stubborn stains such as oil and grease that can be difficult to remove using conventional methods. In addition, this method is much less labor intensive than sanding, grinding or power washing, making it ideal for larger jobs. Finally, it does not produce any hazardous dust or fumes like some sanding methods may do.

Types of Abrasives Used in Concrete Floor Blasting

The type of abrasive material used in concrete floor blasting will depend on the desired outcome. Different types of abrasives can be used to achieve different results – from light cleaning to heavy-duty resurfacing. Generally speaking, softer materials such as crushed walnut shells are used for lighter cleaning and polishing applications while harder materials such as steel shot are used for more aggressive blasting applications. Aluminum oxide is also commonly used in this process due to its durability and cost-effectiveness.

Safety Considerations When Using Concrete Floor Blasting Equipment

Concrete floor blasting equipment should only be operated by trained professionals who understand the proper safety procedures associated with its use. As with any type of machinery there are potential hazards associated with using this equipment that must be taken into consideration before operating it. Protective clothing and accessories must be worn at all times when using this equipment including safety glasses, hearing protection and respirators if necessary. The operator must also ensure that all bystanders are kept at a safe distance from the blast site at all times during operation. Additionally, it’s important that the area being blasted is cleared of any combustible materials before beginning work to avoid the risk of fire or explosion due to friction caused by the abrasive material hitting the concrete surface.

FAQs About Concrete Floor Blasting

Q1: What kind of results can I expect after concrete floor blasting?

A1: After concrete floor blasting you can expect a clean and smooth surface free from dirt, dust and other debris. Depending on the type of abrasive material used you may also see an improvement in the overall appearance of your concrete floor due to polishing effects caused by the blast media hitting the surface at high speed which can leave behind a glossy finish. Additionally, any existing stains or markings will likely be removed during this process leaving you with a clean slate To work with.

Q2: How long does a concrete floor blasting job take?

A2: The length of time it takes to complete a concrete floor blasting job will depend on the size of the area being blasted, the type of abrasive material used and the desired results. Generally speaking, most jobs can be completed within a few hours depending on these factors.