Aerated Concrete Floor Panels

Related Images about Aerated Concrete Floor Panels

Lightweight aerated concrete floor screed roof insulation walls infill and decorative elements

The major concern for most clients for the substandard aesthetics, but currently polished concrete flooring definitely stands out from the opposition for various reasons. These polishing compounds are offered in a great many shops as well as stores where similar items are sold along with one could use them to re instate the gleam on the polished concrete flooring.

Pre-insulated concrete flooring system · PHPD Online

The polished concrete floor appearance is finished with matte to high gloss finishes. Concrete flooring has several excellent traits like it's fire burn resistant, has good resistance to toxic chemicals, is actually basic and its thickness patterning provides long life wear ability.

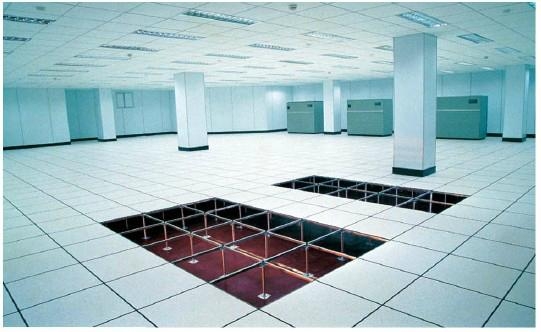

Raised Concrete Floor Systems Pro Access Floors

Sometimes grease, oil or other things can stain concrete floor. The only thing that is going to scrape a concrete floor is a jackhammer. They can be reinforced and so as to be powerful adequate to hold the unwanted weight of a truck. Dying is not the single style option for polished concrete flooring. The dust as well as dirt doesn't stick to the floor, like it does with carpet.

Unifloor Raised Floor at Rs 325/per/sqft Raised Floors ID: 13243706788

Concrete Core Access Floor Panels with HPL/PVC – FOBO (China Manufacturer) – Other Floors

AAC Products – AAC Panels

AAC Products – AAC Panels

Ventilated Concrete Floor

Construction Details – Aercon AAC Autoclaved Aerated Concrete

Construction Details – Aercon AAC Autoclaved Aerated Concrete

Suspended Concrete Floor Systems Nz – Carpet Vidalondon

Construction Details – Aercon AAC Autoclaved Aerated Concrete

Autoclaved aerated concrete

Concrete slab floors YourHome

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Aerated Concrete Floor Panels

Aerated concrete floor panels are an innovative building material that combines the benefits of concrete with the light weight and strength of lightweight aggregate. These panels are composed of a mix of Portland cement, fine sand, and a lightweight aggregate such as vermiculite or perlite. The lightweight aggregate is pre-mixed with the other components and then poured into molds. Once the mixture has been poured into the mold, it is left to cure for several days in order to achieve the desired strength and density.

The resulting panel is highly durable and strong, yet still lightweight enough to be easily installed in most applications. Aerated concrete floor panels have become increasingly popular for use in residential and commercial construction projects due to their energy efficiency, soundproofing capabilities, and fire resistance. Additionally, these panels are extremely resistant to moisture damage, making them ideal for installation in wet or damp environments.

Benefits of Aerated Concrete Floor Panels

Aerated concrete floor panels offer numerous benefits when compared to traditional concrete or other building materials. These include:

Energy Efficiency:

Aerated concrete floor panels are highly energy efficient due to their low thermal conductivity. This means that they can help reduce heating costs by reducing heat loss through floors. Additionally, aerated concrete floor panels can help reduce cooling costs by providing insulation against external temperatures.

Soundproofing:

Aerated concrete floor panels are excellent at soundproofing because they absorb sound waves rather than reflecting them back into the environment. This makes them ideal for construction projects in areas where noise levels need to be kept low, such as hospitals, schools, and offices.

Fire Resistance:

Aerated concrete floor panels are highly fire resistant due to their low combustibility and low smoke emission rates. This makes them ideal for use in areas where fire safety is a top priority, such as public spaces or commercial buildings.

Moisture Resistance:

Due to their high moisture resistance, aerated concrete floor panels are ideal for installation in wet or damp environments such as basements or bathrooms. This makes them a great choice for areas prone to flooding or water damage.

Durability: Aerated concrete floor panels are highly durable and long lasting due to their strength and resistance to wear and tear. Additionally, these panels require very little maintenance once installed, making them an economical choice in the long run.

FAQs on Aerated Concrete Floor Panels

Q1: What is an aerated concrete floor panel?

A1: An aerated concrete floor panel is an innovative building material made from a mix of Portland cement, fine sand, and a lightweight aggregate such as vermiculite or perlite. The mixture is poured into molds and left to cure for several days in order to achieve the desired strength and density. These panels are highly durable yet lightweight enough to be easily installed in most applications.

Q2: What are the benefits of using aerated concrete floor panels?

A2: The benefits of using aerated concrete floor panels include energy efficiency, soundproofing capabilities, fire resistance, moisture resistance, and durability. These characteristics make them an ideal choice for residential and Commercial construction projects.

What are the benefits of aerated concrete floor panels?

1. Thermal efficiency: Aerated concrete floor panels are highly efficient insulators, providing excellent thermal performance and helping to reduce energy costs.2. Sound insulation: Aerated concrete floor panels absorb sound, providing a quieter environment for the home.

3. Durability: Aerated concrete floor panels are strong and durable, making them suitable for high-traffic areas and resisting cracking or chipping.

4. Easy installation: Aerated concrete floor panels can be quickly and easily installed, without the need for specialized tools or materials.

5. Cost-effective: Compared to other types of flooring, aerated concrete floor panels are often cheaper and more cost-effective in the long run.

What are the advantages of using aerated concrete floor panels over traditional materials?

1. Lightweight: Aerated concrete floor panels are much lighter than traditional materials, making them easier to install and transport.2. Thermal insulation: Aerated concrete has excellent thermal insulation properties, making it ideal for controlling energy costs and maintaining a comfortable indoor environment.

3. Fire resistance: Aerated concrete is highly fire-resistant, so it can provide an extra layer of protection against fire damage in the home.

4. Durability: Aerated concrete is highly durable and can last for decades with minimal maintenance.

5. Cost effectiveness: Aerated concrete is a cost-effective material that can save money on building and renovation projects.