Applying Rustoleum Garage Floor Epoxy

Related Images about Applying Rustoleum Garage Floor Epoxy

Rustoleum Garage Floor Coating Application And Usage

It won't affect the appearance of the floor or could it corrode the surface area. Moreover, you ought to additionally consider the air temperature in your storage area. Even in case your loved ones is actually known for their rough and tumble behavior, epoxy flooring won't allow you to down with its superior overall performance.

How to Use Rust Oleum Epoxyshield Garage Floor Coating Kit to Transform Your Floor – YouTube

Epoxy flooring is extremely versatile and comes in a multitude of styles as well. There are two definitions of the task, one from the makers of the item which of the contractors that use them. Success provides the benefits of industrial floors that are long-lasting, stylish and practical at the same time. You may as well take the time of yours to stay away from errors.

10 Reasons to Add a Clear Top Coat to an Epoxy Garage Floor All Garage Floors

The system is quick and simple to use and will get rid of quicker than elastomeric coatings. In order to improve the resilience of its, this coating is done with an aspect of both base and curative elements combined at an appropriate ratio resulting to an exothermic reaction that hardens the coat giving it a hard plastic-made quality. This could ruin the general attractiveness of this floor.

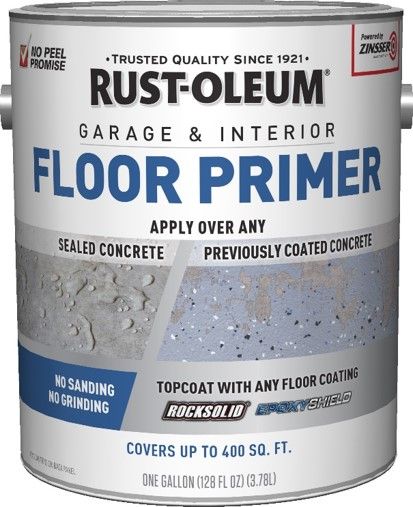

Rust-Oleum Garage Floor Primer makes Recoating Epoxy Easy All Garage Floors

Rust-Oleum 261845 50 Voc – 2.5 Car Epoxy Shield Garage Floor Kit, Gray, Epoxies – Amazon Canada

Easy Garage Makeover and a Giveaway! – Shanty 2 Chic

Easy Garage Floor Coating and a Giveaway! – Shanty 2 Chic

Rustoleum Garage Floor Coating Application And Usage

We Review RockSolid’s Metallic Garage Floor Coating All Garage Floors

The Mariano Project: Garage Floor Epoxy Coating

How to Use Epoxy Garage Floor Coating For Your Floor

The Mariano Project: Garage Floor Epoxy Coating

A RockSolid Metallic Garage Floor Coating Project All Garage Floors

Related Posts:

- Epoxy Resin Floor Finish

- Commercial Grade Floor Epoxy

- Clear Self Leveling Floor Epoxy

- Epoxy Over Laminate Flooring

- Quikrete Floor Epoxy Reviews

- Outdoor Epoxy Resin Flooring

- Epoxy Floor Decals

- Epoxy Terrazzo Flooring Installation

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Flooring Baton Rouge

Applying Rustoleum Garage Floor Epoxy: A Comprehensive Guide

Introduction:

Garage floors are subjected to heavy foot traffic, vehicle impacts, and chemical spills on a daily basis. To protect and enhance the appearance of your garage floor, applying an epoxy coating is an excellent choice. Rustoleum Garage Floor Epoxy is a popular and highly effective product that provides durability, resistance to stains and chemicals, and a glossy finish. In this comprehensive guide, we will walk you through the process of applying Rustoleum Garage Floor Epoxy, from surface preparation to final application.

I. Surface Preparation:

Before applying Rustoleum Garage Floor Epoxy, proper surface preparation is crucial to ensure maximum adhesion and longevity of the coating. Follow these steps for a clean and smooth surface:

1. Clear the area: Remove all items from your garage floor, including vehicles, tools, and storage items. This will allow you to have unrestricted access to the entire floor surface.

2. Clean thoroughly: Sweep or vacuum the entire floor to remove loose dirt and debris. Use a degreaser or detergent solution and scrub brushes to remove any oil stains, grease spots, or other contaminants. Rinse the floor thoroughly with water and let it dry completely.

3. Repair cracks and imperfections: Inspect the floor for any cracks or imperfections. Use a concrete patching compound to fill in these areas and level them with the rest of the floor. Allow ample time for the patching compound to cure before proceeding.

4. Etch the surface: Rustoleum recommends etching the garage floor surface using their Concrete Etch product or a similar muriatic acid solution. This step helps open up pores in the concrete for better adhesion of the epoxy coating. Follow the manufacturer’s instructions for proper dilution ratios and safety precautions while working with acid-based products.

FAQs:

Q1: Can I skip the etching step if my garage floor is new or in good condition?

A1: While etching is not mandatory for all surfaces, it is highly recommended to ensure the best adhesion and longevity of the epoxy coating. Even new or well-maintained floors can benefit from etching to enhance the bond between the coating and the concrete.

Q2: Can I use a pressure washer instead of scrubbing for cleaning the floor?

A2: Pressure washing can be an effective alternative to scrubbing, especially for larger areas. However, make sure to use a suitable detergent or degreaser solution and follow the manufacturer’s instructions. Additionally, allow sufficient time for the floor to dry completely before proceeding with epoxy application.

II. Priming the Surface:

After proper surface preparation, it is essential to apply a primer coat to promote adhesion and prevent moisture-related issues. Rustoleum Garage Floor Epoxy comes with its own primer, which should be applied as follows:

1. Prepare the primer: Mix the two components of the Rustoleum Garage Floor Epoxy primer according to the manufacturer’s instructions. Use a mixing paddle attached to a power drill for thorough blending.

2. Apply the primer: Start by cutting in around the edges of the garage floor using a brush or roller. Then, use a paint roller with an extension handle to apply an even and smooth coat of primer across the rest of the floor surface. Work in manageable sections, applying in a back-and-forth motion.

3. Allow drying time: Follow the recommended drying time mentioned on The product’s label before proceeding to the next step. This usually takes around 4-8 hours, but it’s best to refer to the specific instructions provided by Rustoleum for accurate drying times.

FAQs:

Q1: Can I use a different primer with Rustoleum Garage Floor Epoxy?

A1: It is recommended to use the primer that comes with the Rustoleum Garage Floor Epoxy kit for optimal results. Using a different primer may affect the performance and adhesion of the epoxy coating.

Q2: Can I apply multiple coats of primer for better adhesion?

A2: One coat of primer is typically sufficient for proper adhesion. Applying multiple coats may not necessarily improve the bond between the coating and the concrete and could lead to compatibility issues with the epoxy layer.

III. Applying the Epoxy Coating:

Once the primer has dried, it’s time to apply the epoxy coating. Follow these steps:

1. Prepare the epoxy: Mix the two components of the Rustoleum Garage Floor Epoxy according to the manufacturer’s instructions. Use a mixing paddle attached to a power drill for thorough blending.

2. Begin application: Start by cutting in around the edges of the garage floor using a brush or roller. Then, use a paint roller with an extension handle to apply an even and smooth coat of epoxy across the rest of the floor surface. Work in manageable sections, applying in a back-and-forth motion.

3. Allow curing time: After applying the epoxy, allow it to cure as per the manufacturer’s instructions. This usually takes around 24-48 hours, but it’s important to refer to the specific curing times mentioned on the product label.

4. Optional second coat: If desired, a second coat of epoxy can be applied after the first coat has cured. This can provide additional durability and aesthetic appeal. Follow the same application process as before and allow sufficient curing time between coats.

FAQs:

Q1: Can I add decorative flakes or chips to the epoxy coating?

A1: Yes, Rustoleum offers decorative flakes that can be applied to the epoxy coating to add texture and visual interest. These flakes should be sprinkled onto the wet epoxy surface after applying the first coat and before it cures. Follow Rustoleum’s instructions for proper application techniques.

Q2: How long do I need to wait before using my garage after applying the epoxy coating?

A2: It is recommended to wait at least 72 hours after the final coat has cured before subjecting the garage floor to heavy traffic or placing heavy objects on it. This allows the epoxy to fully cure and harden for maximum durability.