Epoxy Flooring Technical Details

Related Images about Epoxy Flooring Technical Details

33+ Commercial Kitchen Epoxy Flooring Cost PNG – Epoxy Floor

Epoxy floors are not difficult to clean and are amazingly resistant to bacteria. In earlier days, epoxies flooring coatings were limited to merchandise retailers, but with the creation of technology, they've become a pattern for flooring needs in industries, hospitals, garages, warehouses, factories, showrooms, and government facilities brightening up the flooring surfaces.

Epoxy Flooring Service, Thickness: 0.5 Mm, Rs 18 /square feet Jemkon Private Limited ID

Manufacturing epoxy floors coating products also are good materials for floor beautification. It's incredibly cost-effective and also since it is long-lasting, epoxy flooring is a lasting investment. Especially those companies with heavy machinery in addition to forklifts used at the plant as well as factory. Moreover, epoxy flooring makes concrete visually appealing and simple to clean.

Screed Polyurethane / Epoxy Flooring by Lasercroft Flooring

You can also apply epoxy to damaged floors, an one off epoxy coat will do! Furthermore, you are going to be ready to prolong your floors life span. You can even have a floor that is built entirely from epoxy. This makes the epoxy paint a workable area coat for the industrial surfaces too. Item planning, mixing and software are compromised.

Types Of Epoxy Floorings To see more Read it👇 in 2021 Civil engineering design, Epoxy floor

Epoxy Flooring at Best Price in India

Portfolio Archive – DCI Flooring Industrial Seamless Floors and Walls

Vinyl Flooring & Tiling Singapore – FloorCube Flooring Contractor Singapore

Epoxy Flooring Services, Thickness: 0.2 Mm To 10 Mm, ID: 14402032673

Decorative Epoxy Flooring, For Industrial, Thickness: 2 Mm, Rs 35 /square feet ID: 22465027188

Clear Epoxy Resin Flooring: What You Need to Know – Florock

Residential Epoxy Flooring Service JH3 Company

.jpg)

Epoxy Floorings – Moisture Insensitive Injection Resin-Sikadur-53 (UF) Distributor / Channel

Industrial Flooring Contractor Retail & Commercial Flooring Boisco

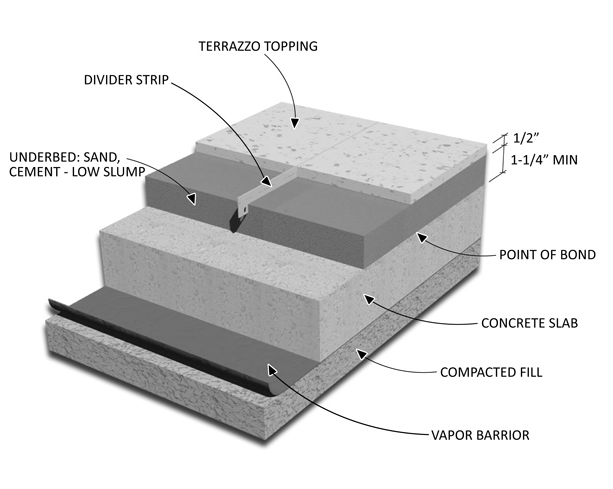

Terrazzo Types and Systems – Terrazzo Installation Experts Los Angeles, CA – Top End Terrazzo

Related Posts:

- Epoxy Resin Floor Finish

- Commercial Grade Floor Epoxy

- Clear Self Leveling Floor Epoxy

- Epoxy Over Laminate Flooring

- Quikrete Floor Epoxy Reviews

- Outdoor Epoxy Resin Flooring

- Epoxy Floor Decals

- Epoxy Terrazzo Flooring Installation

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Flooring Baton Rouge

Epoxy Flooring Technical Details

Epoxy flooring is a popular choice for many commercial and industrial spaces due to its durability, affordability, and ease of installation. It is also gaining popularity in residential applications due to its ability to create a unique look that stands out from traditional flooring materials. It is important to understand the technical details of epoxy flooring before making a decision on what type of flooring to install. In this article, we will review the technical details of epoxy flooring and answer some frequently asked questions about the material.

What is Epoxy Flooring?

Epoxy flooring is a type of coating system that is applied as a liquid or slurry onto concrete surfaces. It creates an impermeable layer that provides protection against damage and wear from foot traffic, chemicals, and other substances. The composition of epoxy flooring includes resins, hardeners, pigments, fillers, and other additives that combine to create a durable surface with excellent adhesion properties.

Benefits of Epoxy Flooring

Epoxy flooring has several benefits that make it an attractive option for many applications. These benefits include:

– Durability: Epoxy floors are highly resistant to physical damage and abrasions, making them ideal for high-traffic areas.

– Chemical Resistance: Epoxy floors are also able to resist many chemicals and spills, making them ideal for industrial applications where chemicals are present.

– Ease of Installation: Epoxy floors can be easily installed by professionals or do-it-yourselfers with minimal preparation required.

– Low Maintenance: Epoxy floors require very little maintenance once installed and can last for years with proper care.

– Aesthetic Appeal: Epoxy floors come in a variety of colors and textures that can be customized to create unique looks for any space.

Types of Epoxy Flooring

There are two main types of epoxy flooring: solvent-based and water-based epoxies. Solvent-based epoxies are more durable than water-based epoxies but may require additional preparation before application. Water-based epoxies are easier to apply but may not be as durable as solvent-based epoxies. Both types come in a variety of colors and textures that can be customized to suit any design requirements.

Installation Process for Epoxy Floors

The installation process for epoxy floors will vary depending on the type of epoxy being used and the specific requirements of the project. Generally speaking, the installation process involves cleaning and preparing the substrate surface, applying primer if needed, mixing the components together according to manufacturer directions, pouring or troweling the mixture onto the surface, allowing it to cure completely before applying any additional coats or topcoats if necessary.

Maintenance Requirements for Epoxy Floors

Epoxy floors require very little maintenance once installed but should be periodically inspected for signs of wear or damage such as cracks or chips in the surface. To maintain an epoxy floor’s durability and aesthetic appeal, it should be regularly swept or vacuumed to remove dirt and debris and mopped with warm water and mild detergent if necessary. If any scratches or scuffs appear on the surface they can usually be Removed with a soft cloth and a mild abrasive cleaner.

What type of finish does epoxy flooring have?

Epoxy flooring typically has a high-gloss, stain-resistant finish. It can also be customized to have a matte finish or a textured finish for added traction. The finish of an epoxy floor is highly durable, making it ideal for high-traffic areas and industrial settings.What are the advantages of epoxy flooring?

1. Durability: Epoxy flooring is extremely durable and can withstand heavy foot traffic and equipment without chipping or cracking.2. Chemical Resistance: Epoxy flooring is highly resistant to most chemicals, making it ideal for areas where chemical spills may occur.

3. Low Maintenance: Epoxy flooring requires minimal maintenance and can be easily cleaned with a vacuum or mop.

4. Aesthetic Appeal: Epoxy flooring is available in a wide range of colors and finishes, allowing for nearly limitless design options.

5. Slip Resistance: Epoxy floors offer a high level of slip resistance, making them a safe option for workplaces as well as home garages and basements.

What are the disadvantages of epoxy flooring?

1. Expensive: Epoxy flooring is more expensive than traditional flooring options such as tile, linoleum, or carpet.2. Difficult to repair: If an area of epoxy flooring becomes damaged, it can be difficult to repair without completely replacing the entire floor.

3. Installation time: Installing epoxy flooring can be a long and tedious process that requires expertise and specialized tools.

4. High maintenance: Epoxy flooring needs to be regularly cleaned and maintained in order to keep it looking its best.

5. Slippery: Epoxy floors can become slick when wet and may require the use of special non-slip coatings to prevent accidents.