Epoxy Floor Installation Tools

Related Images about Epoxy Floor Installation Tools

Epoxy Floor Design Tool Epoxy Floor

This helps the floor to keep going longer. You need to make certain that the epoxy is actually a low odor epoxy and be careful to utilize proper ventilation when applying the new epoxy flooring of yours. Epoxy is also waterproof and dust proof, and thus cleaning a sealed floor is quick and easy. Due to the application of an inorganic layer, it repels dust, water, chemicals, dirt and stains.

ACCESSORIES & TOOLS

In terms of design and look, epoxy coated flooring is among the fastest and best methods of giving that giant "lift" to the look of the floors of yours. Flooring that produces moisture typically eliminate the power of the epoxy to connect. You will reduce the life of your epoxy flooring if you cook the surface in which you prefer to set up it improperly.

Questions Your Epoxy Contractor Should Ask Before Installing Your Commercial Epoxy Floor

You can also pick the appearance of the epoxy to match up with the look you would like to accomplish in your location. This means not simply is it going to not be damaged by substance floor cleaners, however, if a laboratory has epoxy flooring and certain chemical substances spill, it will not ruin the floor. Carpet stains quickly & traps dust and dirt within.

How to Choose a Great Epoxy Floor Contractor – Dynamic Floor Coating

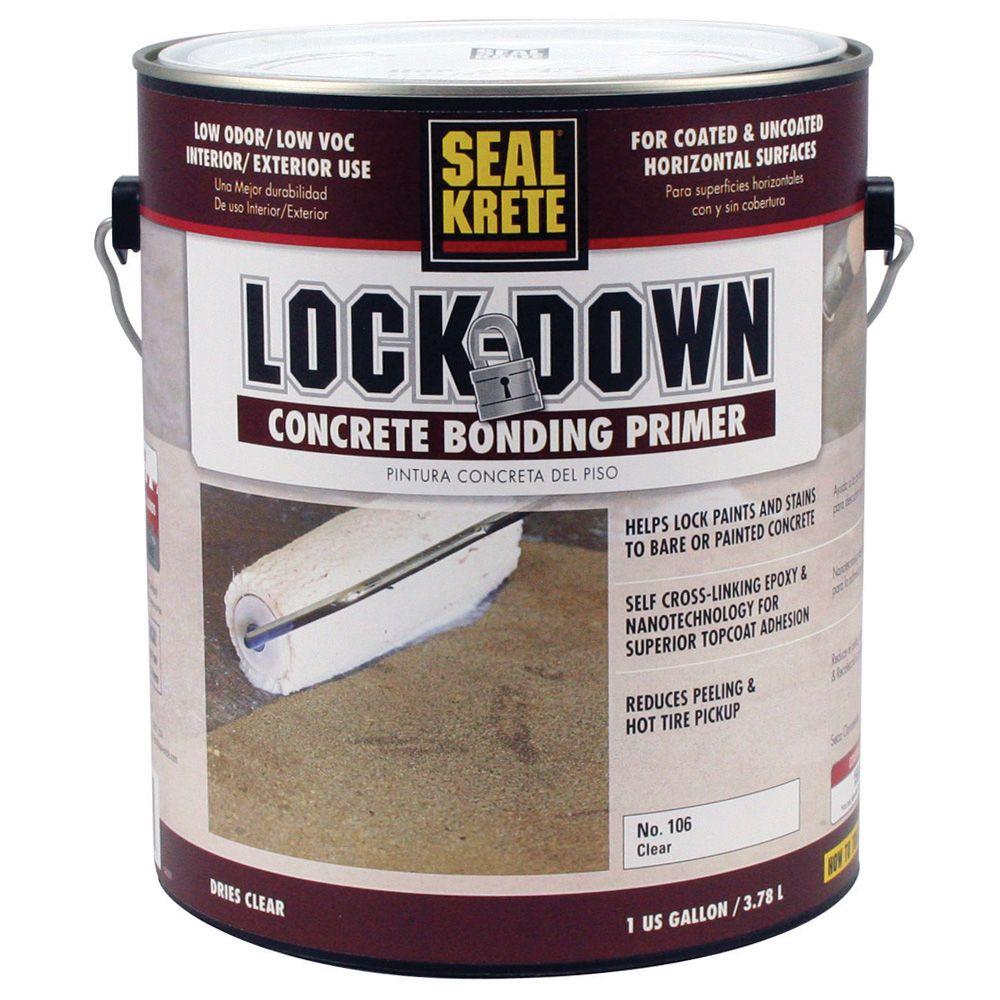

Seal-Krete Lock-Down 1 gal. Epoxy Bonding Floor Primer-106001 – The Home Depot

Key consideration for installation of an epoxy flooring system

3D Epoxy Flooring – GZ Industrial Supplies

HOW-TO Epoxy Floor Application (Part 2) Xtreme Polishing Systems – YouTube

Foundation Armor Epoxy 2 gal. Water-Based Clear High Gloss 2-Part Epoxy Primer and Top Coat for

Epoxy Terrazzo Colors – Terrazzo Installation Experts Los Angeles, CA – Top End Terrazzo

Self-leveling Epoxy Floor Coating Package Duraamen

Epoxy Cove Form – 3 Part Complete Package Resins Direct

Checking and Correcting Framing – Framing Basics – Drywall Installation, Repair & Tips. DIY Advice

Spike Shoes (1 Pair) – Epoxy Floor Supply

Related Posts:

- Epoxy Resin Floor Finish

- Commercial Grade Floor Epoxy

- Clear Self Leveling Floor Epoxy

- Epoxy Over Laminate Flooring

- Quikrete Floor Epoxy Reviews

- Outdoor Epoxy Resin Flooring

- Epoxy Floor Decals

- Epoxy Terrazzo Flooring Installation

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Flooring Baton Rouge

Epoxy Floor Installation Tools: Everything You Need to Know

When it comes to installing an epoxy floor, having the right tools is essential. The quality of the installation depends on the tools that are used. If you don’t have the right tools, you could end up with a floor that looks bad or doesn’t last as long as it should. In this article, we’ll take a look at some of the essential tools you need for epoxy floor installation and discuss how they can help you achieve professional results.

What Tools Are Needed for Epoxy Floor Installation?

When it comes to installing an epoxy floor, there are several tools that you need. Some of the essential tools include:

– A concrete grinder: A concrete grinder is used to prepare the surface of the concrete to ensure that it is free of dirt, debris, and other contaminants. This will ensure that your epoxy coating adheres properly and lasts longer.

– Trowel: A trowel is used to spread the epoxy evenly on the surface so that it covers all areas evenly. It is important to make sure that you get a good bond between the epoxy and the concrete so that your floor lasts longer and looks better.

– Squeegee: A squeegee is used to spread out the extra epoxy on the surface so that it doesn’t pool in any one area. This will also help ensure a nice even finish and uniform coverage over the entire floor.

– Roller brush: A roller brush is used to smooth out any air bubbles or imperfections in the epoxy before it sets. This will help ensure a professional finish with no lines or streaks.

– Polyester brushes: Polyester brushes are used after the epoxy has been applied to help create a smooth finish. They can also be used to create decorative patterns in the epoxy if desired.

– Safety equipment: Safety equipment such as goggles and gloves should always be worn when working with epoxies as they can be toxic if inhaled or swallowed.

FAQs About Epoxy Floor Installation Tools

Q1: What kind of safety equipment do I need when working with epoxies?

A1: When working with epoxies, it is important to wear safety equipment such as goggles and gloves as these chemicals can be toxic if inhaled or swallowed. It is also important to make sure that any area where you are working is well ventilated so that fumes can escape safely.

Q2: How do I know which type of trowel to use?

A2: The type of trowel you choose will depend on the type of epoxy material you are using and how thick it is. Generally speaking, if your material is thicker than 1/8 inch, then you should use an angled trowel with a notched edge for better coverage. If your material is thinner than 1/8 inch, then a flat trowel should be sufficient.

Q3: What type of roller brush should I use?

A3: The type of roller brush you use will depend on how much coverage you need and how much pressure you want to apply while rolling out the ep Oxy. Generally speaking, a heavy-duty roller brush with a long handle is best for larger areas and a smaller roller brush with a shorter handle is better for smaller areas.

What type of tools are needed for epoxy floor installation?

Tools needed for epoxy floor installation include a long-handled squeegee, roller frame and roller cover, paintbrush, utility knife, measuring tape, mixing buckets, rubber gloves, respirator mask, rubber mallet, and a power drill. These tools are necessary to properly prepare the surface, mix the epoxy components, spread the epoxy, and finish the floor. Additionally, safety equipment such as goggles and protective clothing should always be worn when working with epoxies for your safety.What is the difference between epoxy floor coating and polyurethane floor coating?

Epoxy floor coating is a two-part system that cures to form a hard, durable surface. It is often used in commercial and industrial settings due to its superior durability and resistance to chemicals, oil, and water. Polyurethane floor coating is a one-part system that is applied as a liquid and dries to form a soft, flexible finish. It is often used in residential settings due to its ease of application and its ability to provide a glossy finish that can be easily cleaned.What are the advantages and disadvantages of epoxy floor coating versus polyurethane floor coating?

Advantages of Epoxy Floor Coating:1. Epoxy floor coatings are generally easier to install and can be applied in just one or two coats.

2. Epoxy floor coatings are highly durable and can last for years if properly maintained.

3. Epoxy floor coatings are resistant to water, oil, and most chemicals.

4. Epoxy floor coatings are cost-effective, with a lower upfront cost than polyurethane floor coatings.

5. Epoxy floor coatings come in a variety of colors, so you can choose the look that best suits your needs.

Disadvantages of Epoxy Floor Coating:

1. If not properly installed, epoxy floor coatings can be prone to cracking or bubbling over time due to temperature changes or moisture exposure.

2. They also require more frequent maintenance than polyurethane coatings, as they are more susceptible to wear and tear over time.

3. They also tend to be less flexible than polyurethane coatings, which can make them more difficult to work with when it comes to installation and repairs.

4. Lastly, epoxy floor coatings are not as scratch-resistant as polyurethane coatings, so they may need to be refinished sooner than polyurethane floor coatings would need to be.

Advantages of Polyurethane Floor Coating:

1. Polyurethane floor coatings are extremely strong and durable and can last for many years if properly maintained.

2. Polyurethane floor coatings are also highly resistant to scratches and wear and tear, so they require less frequent maintenance than epoxy floor coatings do.

3. They also offer a higher degree of flexibility than epoxy floor coatings, which makes them easier to work with when it comes to installation and repairs.

4. Lastly, polyurethane floor coatings come in a variety of colors and finishes so that you can choose the look that best suits your needs while still providing durability and protection against wear and tear over time.

Disadvantages of Polyurethane Floor Coating:

1. Polyurethane floor coatings have a higher upfront cost than epoxy floor coatings due to the materials used in their construction and the extra labor involved in installation and maintenance over time.

2. Polyurethane floor coatings may not be as resistant to water or certain chemicals as epoxy floor coatings are, so extra caution must be taken when cleaning up spills or messes around these areas of the home or business establishment where these types of floors may exist