Typical Concrete Floor Construction

Related Images about Typical Concrete Floor Construction

Floor construction stock image. Image of worker, engineering – 37393365

Another outstanding characteristic of locations which have polished concrete floors is the fact that there is a high feeling of hygiene amongst the individuals there. Concrete may be a great option for flooring though it probably isn't for everyone. However there are also other kinds of concrete that happen to be a lot more chic and stylish.

Reinforced Concrete,floor Construction Stock Photo – Image: 37372952

Therefore concrete flooring has grown to be the original choice of not the household but even the commercial and business owner. In winter, it becomes more dry and retains the warmth of this sun. The edge is that when it comes to polished concrete flooring, one can easily be certain the original appearance will be able to be re-instated. The diamond concrete polishing procedure is uncomplicated.

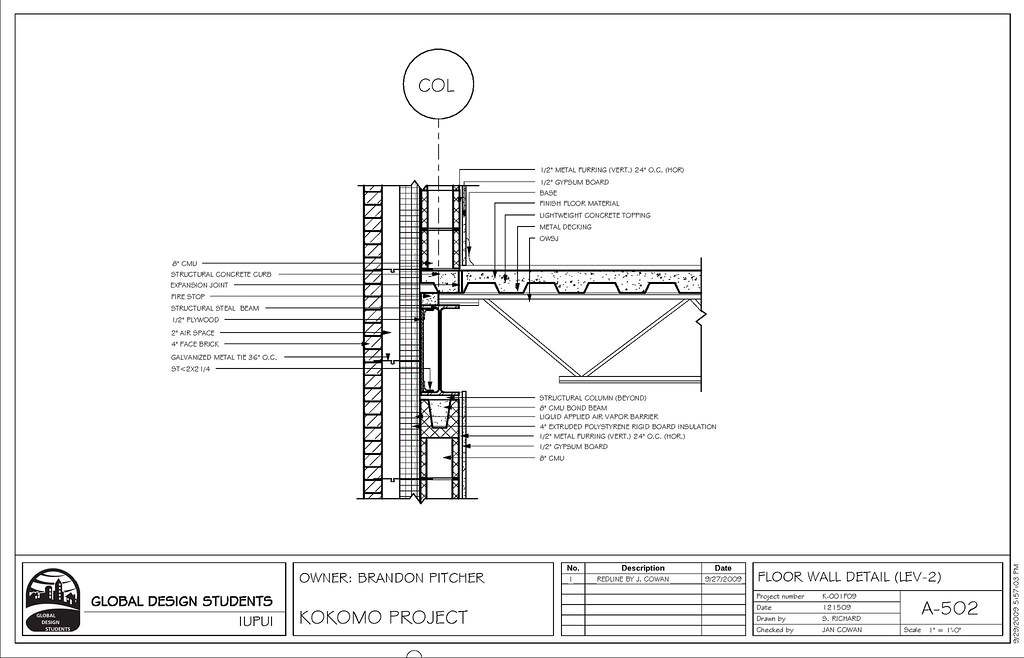

TYPICAL FLOOR WALL DETAIL ART 222: Commercial Construction… Flickr

There are a variety of different strategies you are able to use to concrete flooring to create gorgeous decorative floors suitable for both the office of yours and the home of yours. In the event that you would like to drive a tank of it, when poured, concrete should get it. With acid stained concrete flooring, you've choices available to satisfy the design must have of yours.

Detail Of Reinforced Concrete Stock Image – Image of manual, construction: 37373309

Acoustic Floating Floors – Farrat Jackup Floating Floor System

Concrete flooring for Commercial Buildings, Precast Concrete UK

M.Construction Services Concrete Floors

The Slab on Grade Installation DIY Radiant Floor Heating Radiant Floor Company

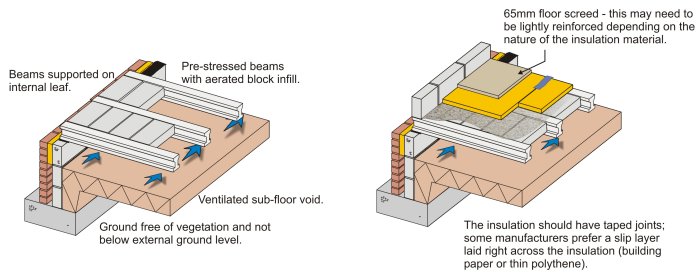

6. Ground Floors – Construction Studies

Pouyan Madanipour SRT251: May 2008

Industrial Concrete Flooring Finishes – Polishing & Coatings – The Concrete Network

ICF Blocks: Buy R22 & R30 Insulated Concrete Forms Amvic Insulated concrete forms, Concrete

Footings Foundations And Slabs – House Construction

NEO PVC WATERSTOP ICJ – Sheridan

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction

Concrete floors are an integral part of many construction projects, providing the foundation for a variety of structures. While they may seem intimidating to construct, concrete floors are actually quite easy to build with the right supplies and know-how. In this article, we’ll cover the basics of typical concrete floor construction, including the materials and tools you’ll need, how to prepare your site, and how to lay and finish the concrete.

Materials and Tools Needed

To construct a concrete floor, you’ll need the following materials and tools:

– Concrete mix: The type of concrete mix you choose will depend on the purpose of your floor and your budget. Generally speaking, a basic mix is good for most applications, but if your floor will be holding heavy loads or exposed to water frequently, you may want to use a higher-strength mix.

– Sand: If you’re using a basic mix, you’ll also need to purchase some sand to help bind the mix together.

– Rebar: Rebar is essential for reinforcing the concrete and making sure it’s strong enough to withstand pressure.

– Forming material: You can use wood, steel, or plastic to form your concrete. Each has its own advantages and disadvantages; for example, steel forms are stronger but more expensive than wood forms.

– Trowel: A trowel is needed for spreading and leveling out the concrete before it sets.

– Power mixer: If you don’t want to do all the mixing by hand, you can rent or buy a power mixer which will make it much easier.

– Waterproofing material: Depending on where your floor is located, you may also need to purchase waterproofing material such as a sealant or waterproof paint. This will help protect your floor from water damage over time.

Preparing Your Site

Before beginning construction on your concrete floor, it’s important to take some time to prepare your site. This includes removing any debris or vegetation that might interfere with construction as well as leveling off any uneven surfaces in the area. Additionally, make sure that there are no underground utilities that could be damaged during construction.

Laying the Concrete

Once your site is prepped and ready for construction, it’s time to start laying the concrete. Begin by pouring in your sand if necessary and then mix in your concrete until it reaches a workable consistency (this should take about five minutes). Once mixed, pour it into the forms that you have built and spread it out evenly with a trowel or similar tool. Make sure that all corners are filled completely and that no air pockets remain underneath the surface of the concrete when finished. Allow the concrete to dry overnight before proceeding with finishing touches like smoothing out any rough edges or adding any decorative features such as colored stones or imprinted designs.

Finishing Touches

Once your concrete has dried overnight it should be cured enough for any finishing touches that you want to add. This can include sealing with a waterproof sealant or painting with waterproof paint if desired. Additionally, if there are any rough edges left behind from forming or troweling they can be easily Smoothed out with a grinder or sand paper. Once all finishing touches are complete, your concrete floor is ready to be used!

What are the steps involved in constructing a concrete floor?

1. Prepare the substrate: Make sure the floor is clean and free of debris. Any existing cracks, bumps, or unevenness should be leveled out with a concrete patching compound.2. Install rebar: Lay out steel reinforcement bars (or rebar) into the floor to give it extra strength and stability. The rebar should be placed over a layer of wire mesh for additional support.

3. Pour the concrete: Mix the concrete and pour it onto the floor, making sure it’s evenly distributed. Leave enough space between the rebar for expansion joints, and make sure to finish troweling the surface so it’s completely flat and level.

4. Allow curing time: Allow the concrete to cure for at least 24 hours before walking on it or applying any sealants or other finishes. Be sure to keep the concrete damp during this time for best results.

5. Finish the floor: Once the concrete has cured, you can apply any desired finishes, such as a sealant or paint. This will help protect the concrete and make it look better.

What tools are needed for constructing a concrete floor?

1. Concrete Mixer2. Trowel

3. Power Floater

4. Bull Float

5. Kneeboards

6. Masonry Adhesive

7. Concrete Sealer

8. Expansion Joints

9. Joint Filler

10. Caulking Gun

11. Level

12. Grinder

13. Brush

14. Broom

15. Shovel