Concrete Floor Insulation Regulations

Related Images about Concrete Floor Insulation Regulations

Floors insulation

On top of this, one of the best attributes of concrete flooring is its trouble free cleaning function where the particles of dust can be mopped. Although many don't consider a concrete floor in their house for the fear of it being very cold, the opposite is actually true. For daily regimen, a gentle broom or dust mop is very effective.

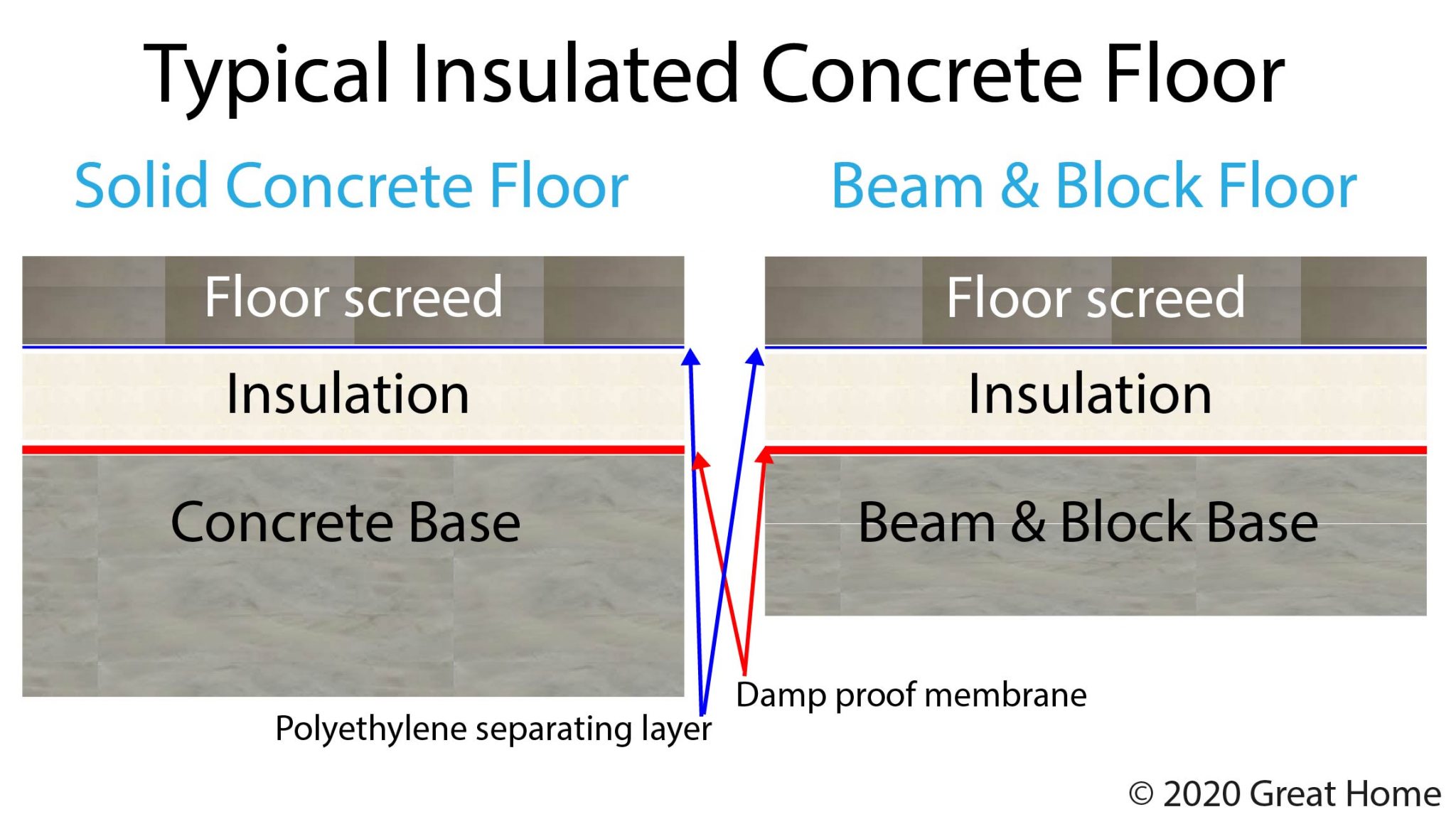

Floor Insulation – Great Home

In case you are contemplating a polished concrete floor then your very first choice is going to be whether or not you stain the flooring. Furthermore, floors comprised of concrete are actually durable, costs cheaper due to lower fee of labor and also easy to clean compared to other flooring sorts. Treated concrete floors are some of the world's most durable.

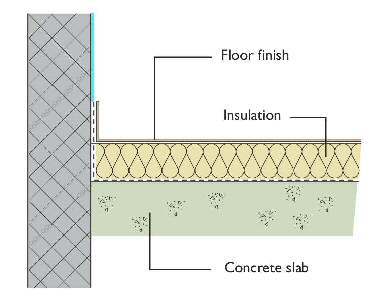

Modern Methods of Insulation of Concrete Floor – Best Landscaping Ideas

At the end of this working day, the polished concrete floor is going to look something like some kind of polished stone, no surprise it is applied as a decorative ways in so many locations. In case the concrete floor has been in the past sealed, it is a good idea to sweep and then mop the area with soapy water, a standard cleaning product or even an experienced concrete cleaner.

How To Insulate A Garage Floor Conversion – Carpet Vidalondon

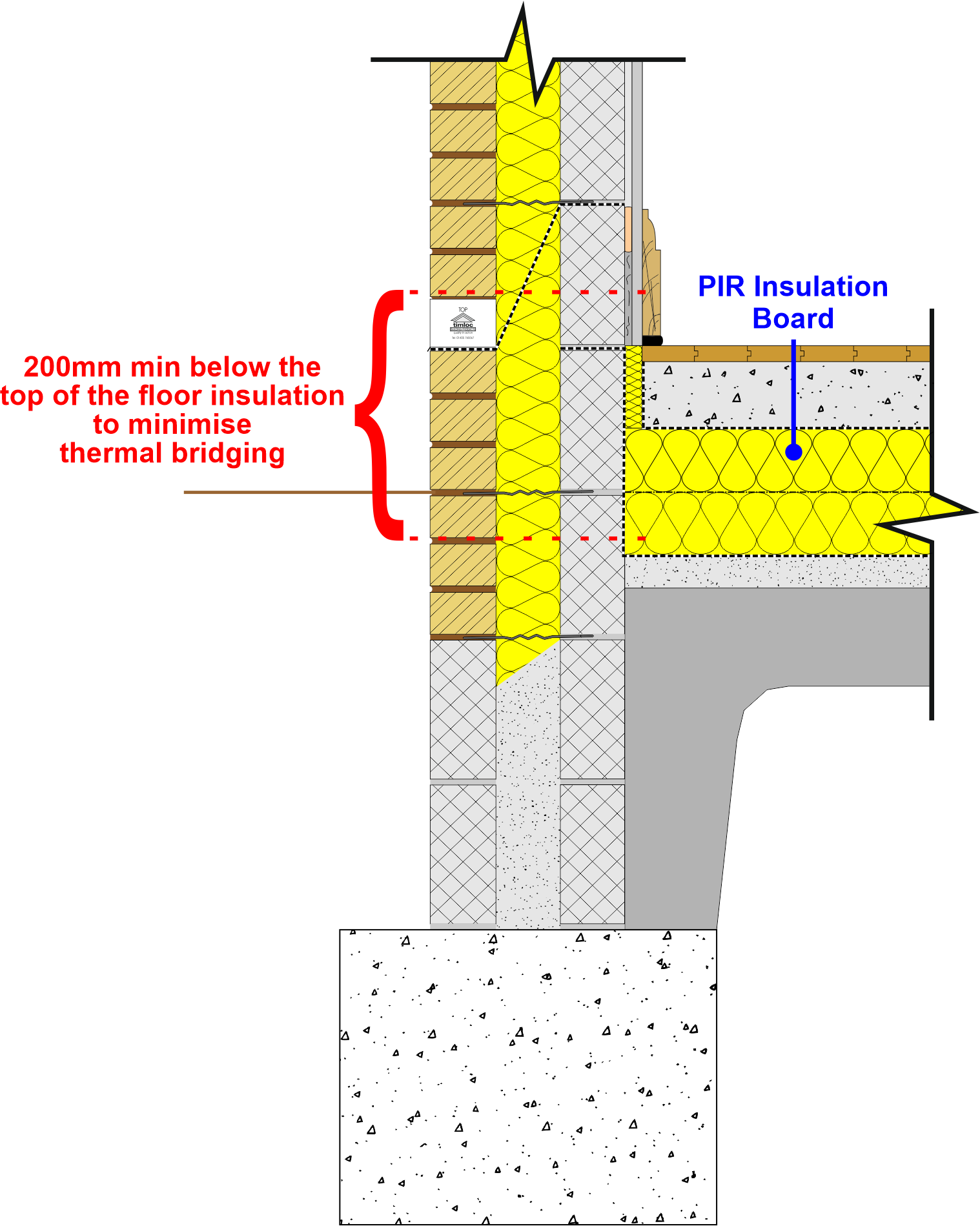

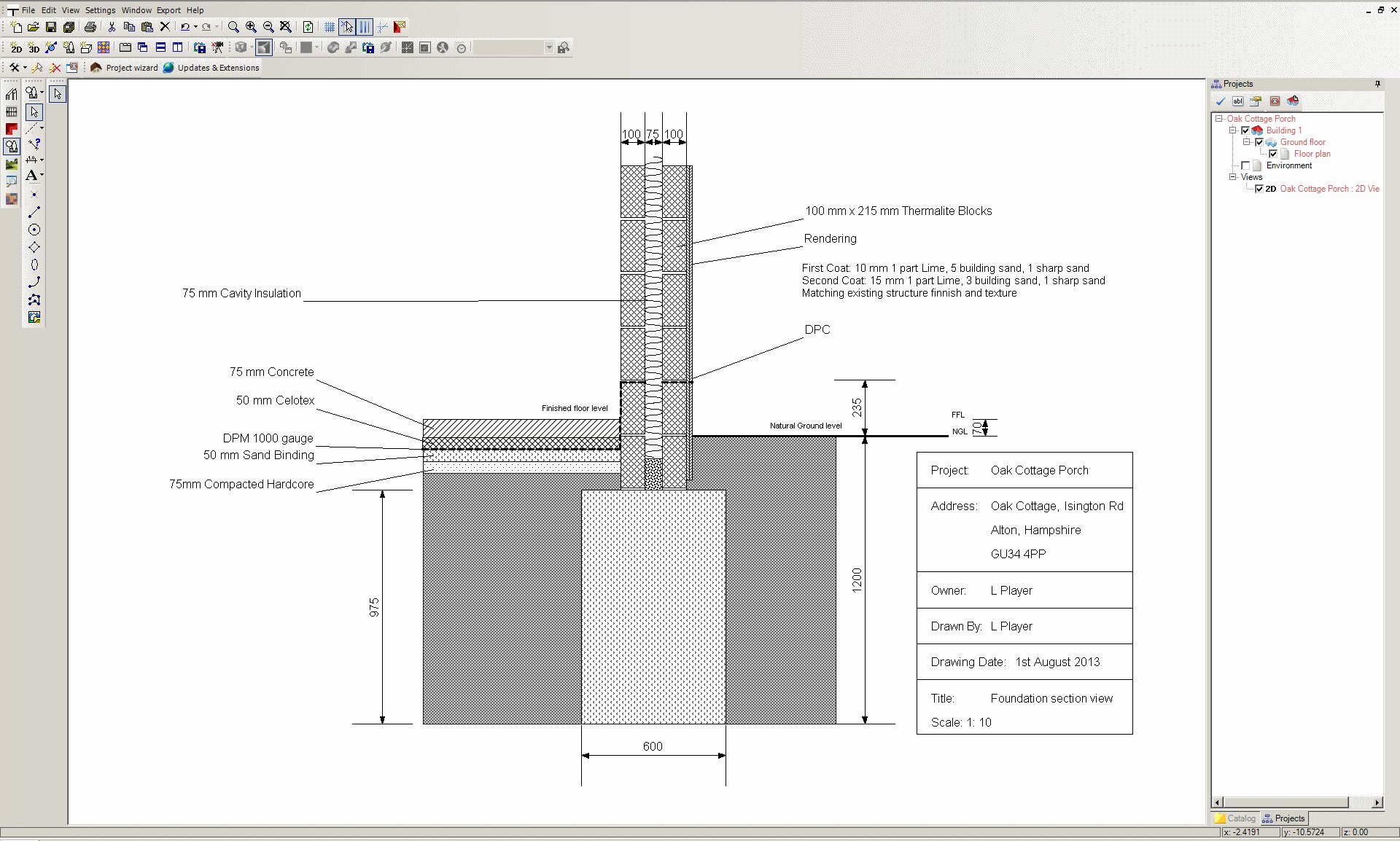

Technical Building foundation, Construction drawings, Cavity wall

What is Insulation and How Does it Work? EDF

Modern Methods of Insulation of Concrete Floor – Best Landscaping Ideas

Building Regulations

Info-511: Basement Insulation — Building Science Information Basement insulation, Interior

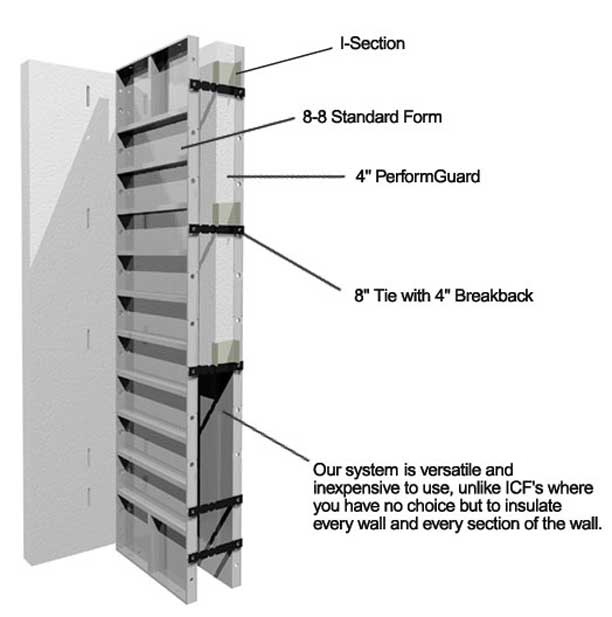

Concrete Form Accessories – Insulation

How To Insulate A Garage Floor Conversion – Carpet Vidalondon

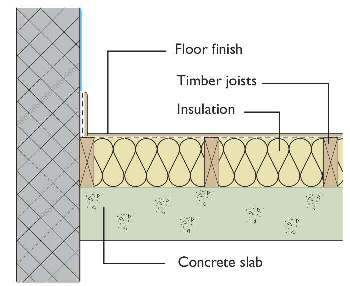

Floor design, Floor insulation, Flooring

ROCKWOOL Loft Insulation Dense Stone Wool Loft Insulation

Concrete Floors and Replacing a Timber Floor with Concrete After Dry Rot DIY Doctor

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Concrete Floor Insulation Regulations: Everything You Need to Know

When it comes to the installation of concrete floor insulation, there are certain regulations that need to be followed. These regulations can vary depending on where the insulation is being installed and the purpose for which it is being used. Understanding these regulations is essential for anyone looking to install concrete floor insulation in order to ensure that the job is done correctly and safely. In this article, we’ll take a look at some of the different regulations that need to be adhered to when installing concrete floor insulation, as well as some frequently asked questions about the process.

Types of Concrete Floor Insulation

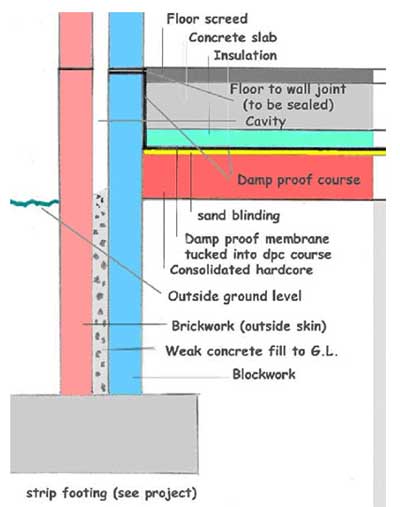

Before delving into the regulations surrounding concrete floor insulation, it is important to understand the different types of insulation available. Generally speaking, there are two main types of concrete floor insulation: rigid foam and loose fill. Rigid foam insulation is a sheet product that can be cut and fitted around pipes and other obstructions in the floor. It’s also typically installed below grade or in between joists. Loose fill insulation, on the other hand, is made up of small particles of cellulose or fiberglass and can be poured into wall cavities or onto a concrete slab.

Building Code Requirements

The building code requirements for concrete floor insulation depend on several factors, including climate zone, type of construction, and building use. For example, residential buildings in cold climates will typically require thicker layers of insulation than those in hot climates. Additionally, commercial buildings will usually require more insulation than residential buildings due to higher fire safety requirements. The building code requirements for your particular project should be consulted prior to beginning any work.

Installation Guidelines

In addition to building code requirements, there are also certain guidelines that must be followed when installing concrete floor insulation. For instance, it’s important to make sure that all joints between sheets are sealed properly with caulk or tape in order to prevent air infiltration or moisture buildup. Additionally, if loose fill insulation is being used it’s important to make sure that it’s evenly distributed throughout the area being insulated in order to ensure optimal performance. Finally, when installing rigid foam sheets it’s important to make sure that they are cut accurately in order to fit properly around any obstructions such as pipes or ductwork.

Fire Safety Regulations

When installing concrete floor insulation, it’s also important to comply with local fire safety regulations. This may include using fire-resistant materials such as mineral wool or fiberglass for certain applications or ensuring that all electrical wiring and equipment is properly grounded and insulated from potential fire hazards. Additionally, when installing rigid foam sheets it may also be necessary to provide additional fire protection measures such as covering them with a layer of drywall or other fire-resistant material.

FAQs About Concrete Floor Insulation Regulations

Q: What kind of materials should I use for concrete floor insulation?

A: The type of material used for concrete floor insulation depends on several factors such as climate zone, type of construction, and building use. Generally speaking, rigid foam sheets are often used in residential buildings while loose fill materials such as cellulose or fiberglass may be used in commercial buildings due to their fire resistance properties. It’s important to consult local Building codes and fire safety regulations prior to beginning any project.

The building code requirements for concrete floor insulation depend on several factors, including climate zone, type of construction, and building use. For example, residential buildings in cold climates will typically require thicker layers of insulation than those in hot climates. Additionally, commercial buildings will usually require more insulation than residential buildings due to higher fire safety requirements. Rigid foam sheets are often used in residential buildings while loose fill materials such as cellulose or fiberglass may be used in commercial buildings due to their fire resistance properties. It’s important to consult local building codes and fire safety regulations prior to beginning any project. Additionally, when installing rigid foam sheets it’s important to make sure that they are cut accurately in order to fit properly around any obstructions such as pipes or ductwork. Furthermore, it’s also important to comply with local fire safety regulations when installing concrete floor insulation, which may include using fire-resistant materials and ensuring that all electrical wiring and equipment is properly grounded and insulated from potential fire hazards.