Concrete Floor Tile Molds

Related Images about Concrete Floor Tile Molds

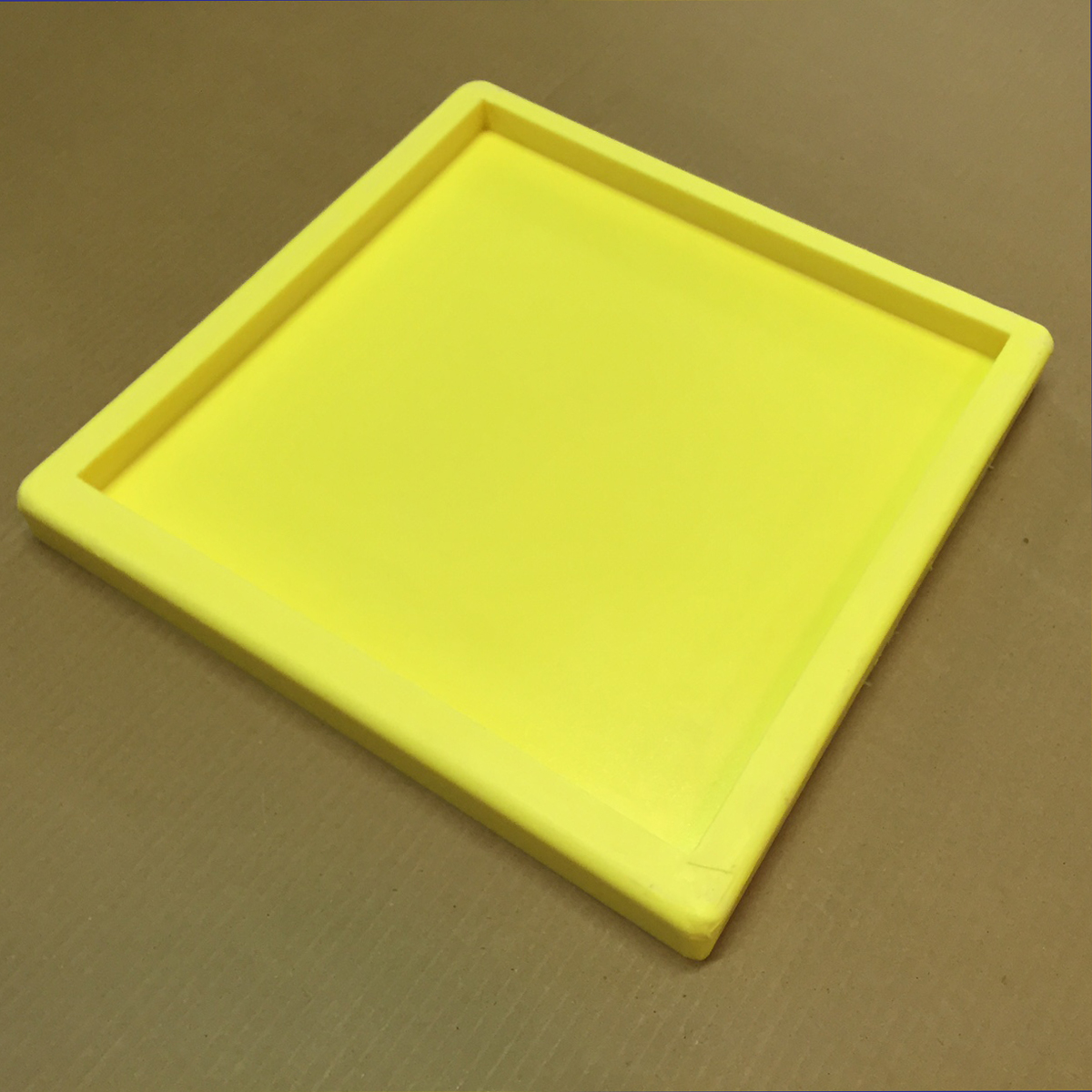

Precast Decorative Cement Concrete Tile Mold For Floor Paving – Buy Decoration Concrete Tile

Concrete floors tend to get chilly particularly on colder temperature so before the cement combination is actually poured on the floor, sparkling floor pipes or adaptable tubing are first laid on the outside. If you are searching for a flooring solution for your home project which combines elegance and simplicity, then you definitely will need to explore polished concrete floors.

Smooth Finish Concrete Tile Molds – EJ3 Incorporated

Concrete flooring is actually increasing in popularity and not just with commercial and industrial buildings, polished concrete floors is a best choice in most homes across the nation. Concrete flooring is actually safe, healthy and more comfy for children, the parents of yours and for your entire family. Cleaning couldn't be any easier when you've chosen to add in concrete polishing floors to your property.

Do-It-Yourself Cement Patio Diy concrete patio, Cement patio, Diy patio

They are generally resilient to injury, easy to keep and simple to clean. While some individuals love to use granite or slate for floors, concrete floor is often equally as gorgeous and a great deal less expensive. When cleaning polished concrete floor surfaces, you don't have to depend on harsh chemical cleaners anymore.

Stamped and stained concrete patio that looks like terracotta tile. Concrete stain patio

Precast Decorative Cement Concrete Tile Mold For Floor Paving – Buy Decoration Concrete Tile

Precast Decorative Cement Concrete Tile Mold For Floor Paving – Buy Decoration Concrete Tile

Expressions LTD – Concrete Molds Forms Supplies and Unique Decor – Expressions-LTD Stencil

interlocking paver molds rubber concrete tiles molds, View rubber concrete tiles molds, LYA

Designer Concrete Tile Mould Concrete Floor Tiles Mould Rubber Paver Mould Plastic Paver

SIX 6×12 DIY RUSTIC CONCRETE BRICK MOLDS MAKE BRICK VENEER WALL TILE FOR PENNIES

Concrete Tile Molds — Concrete Design School

3 TILE MOLDS MAKE 100s OF 12×18 TILES @ $0.35 SQ. FT. FOR CONCRETE FLOORS WALLS eBay

A mold for making cement tile. The tile is built updsdie down. Cement tile, Cement, Gorgeous tile

Flexible Concrete Stamp Mats For Paving Decorative Concrete Molds – Buy Concrete Stamp Mats

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floors In Homes Cost

- Level Concrete Floor With Plywood

- Concrete Floor Construction For Underfloor Heating

- Stained Concrete Floors In Basement

- Polished Concrete Floor Crack Repair

- Concrete Floor With Insulation

- Acid Stained Concrete Floors Pictures

- Installing Underfloor Heating On Existing Concrete Floor

- How Much Is Concrete Flooring

Introduction to Concrete Floor Tile Molds

Concrete floor tile molds are a great way to make your own beautiful and unique tiles for home or business. These molds are used to create an array of decorative and functional tiles, from small mosaic tiles to large-scale floor tiles. With the right materials and tools, you can easily create stunning tiles that are both affordable and long-lasting. In this article, we will explore the basics of concrete floor tile molds, their benefits, and how to use them.

What Are Concrete Floor Tile Molds?

Concrete floor tile molds are specially designed plastic or silicone forms that are used to create decorative concrete tiles. These molds come in a variety of shapes and sizes, allowing you to create intricate designs for floors, walls, backsplashes, and other surfaces. They can be used with any type of concrete mix, including those made with sand and aggregate or those made with a polymer additive for improved strength. The concrete is poured into the mold and allowed to harden before being removed.

Benefits of Concrete Floor Tile Molds

There are several advantages to using concrete floor tile molds over traditional ceramic or porcelain tile molds. First, concrete is much more durable than ceramic or porcelain, making it ideal for heavy traffic areas such as hallways or foyers. Additionally, because concrete is stronger and more resistant to wear than other materials, it requires less maintenance over time. Finally, the design options available with concrete floor tile molds are virtually limitless; you can create intricate patterns or bold geometric shapes that will add character and personality to any room.

How to Use Concrete Floor Tile Molds

Using concrete floor tile molds is relatively simple but requires some preparation beforehand. Before pouring the concrete mix into the mold, it’s important to clean the mold thoroughly with soap and water to remove any dirt or debris that may have accumulated on the surface over time. Once the mold has been cleaned, it’s time to prepare the concrete mix according to the manufacturer’s instructions. After adding any colorants or additives that you may desire, pour the mixture into the mold and spread it evenly with a trowel or spatula. Allow the mixture to cure for at least 24 hours before attempting to remove it from the mold.

Once the tile has been removed from the mold and allowed to cure completely (at least 48 hours), it should be sealed with a clear sealant designed specifically for outdoor use if it is going outside. This sealant will help protect your tiles from dirt and moisture while also making cleaning easier in the future.

FAQs About Concrete Floor Tile Molds

Q: What type of mold should I use?

A: The type of mold you use will depend on your desired design and size of tile you want to make. For small mosaic tiles, thin plastic molds work best since they allow you to easily remove each individual piece without damaging it. For larger tiles, thicker silicone molds are more appropriate since they provide greater structural support during curing.

Q: How do I clean my mold after use?

A: To ensure that your mold remains in good condition for future uses, it is important to clean it thoroughly after Each use. To do this, simply soak the mold in warm, soapy water for about 10 minutes and then scrub it with a soft brush to remove any dirt or debris. Once the mold has been cleaned, rinse it off with clean water and allow it to air dry before storing it.

What materials are used to make concrete floor tile molds?

Concrete floor tile molds are typically made from silicone, rubber, or plastic. They can also be made from metal or other materials. Silicone molds are popular because they are flexible and easy to work with. They also provide a good level of detail when creating intricate shapes or patterns. Rubber molds are also very flexible and durable and can be used for larger tiles or for creating more complex designs. Plastic molds are the most affordable option and are best suited for simple shapes or flat tiles. Metal molds are the most expensive option but are very durable and can be used to create intricate designs.What is the best material to use for concrete floor tile molds?

The best material to use for concrete floor tile molds is silicone. Silicone is non-reactive, heat-resistant, and durable, making it an ideal choice for use in molds. It also produces high-quality tiles with minimal effort and cost. Additionally, silicone molds are flexible and easy to work with, allowing you to create intricate shapes and patterns.What are the benefits of using concrete floor tile molds?

1. Cost Savings – Concrete floor tile molds are an affordable and efficient way to produce concrete tiles in high volumes. This helps reduce the cost of production and the overall cost of the tiles.2. Quick Production Time – With concrete floor tile molds, production time is significantly reduced. This is because all of the necessary components are already designed into the mold, so all that is needed is to pour in the concrete and let it set.

3. Consistent Quality – Since each tile produced with a concrete floor tile mold will be identical to one another, it ensures a consistent quality product every time.

4. Complex Designs – With complex designs or textures, concrete floor tile molds can easily create intricate patterns and shapes in tiles that would otherwise require a lot of manual labor and time if done by hand.