Ceramic Tile Floor Molding

Related Images about Ceramic Tile Floor Molding

MSI Palmetto Walnut 6X36 Matte Porcelain Tile – Floor Tiles USA

You are able to purchase a handcrafted look for your floors with this kind of tile. Mortar is going to come up with the sides of this tile, but this can effortlessly be wiped away. They have the matte finish, clear, opaque, see through, shiny, frosted , plain and along with other etchings. Wood floors who have a high gloss appear beautiful but consider this floor always getting damp and spilled on! It'll eventually rot and warp. Ceramic tiles are a great add-on to each house.

How to Remove Ceramic Floor Tiles BuildDirect® Learning CenterLearning Center

Ceramic tiles are extremely unwilling to water and sudden intense changes in temperature. In order to make stone flooring surfaces, stones of various forms (such as slate, granite, and sandstone) as well as sizes are set up and grouted together to create a floor. There are numerous sorts of marble tiles available on the market that you can select from. Irregular and curved lines are formed in the exact same way.

Refreshing the look of Ceramic Floor Tiles Stone Cleaning and Polishing Tips for Ceramic Floors

There are several ways to educate yourself about tile floors. Take a damp cloth and after that provide it with a mild wipe. Carpet is able to hold up to some bending, vinyl tile is able to flex and twist a little, hardwood floors can twist a little too, however, when tile or maybe stone is actually subjected to forces which push in two different directions at one time, it does not understand how to bend.

Rope Molding: Verde Hoja Talavera Mexican Tile

ceramic tile installation

Veneto Sand 16X32 Matte Porcelain Tile – Porcelain Tile USA

Ceramic Tile Floors

Installing Ceramic Tiles On A Floor Stock Image – Image of contractor, redesign: 43611207

Understanding Tile Underlayment at The Home Depot

Parents of a Dozen: How to Prepare a Floor For Ceramic Tile

Pin on New house

Adella Viso White 12X24 Satin 3D Matte Ceramic Tile – Floor Tiles USA

Castle Beige Versailles Tyrrhenia White Porcelain Pattern Tile – Floor Tiles USA

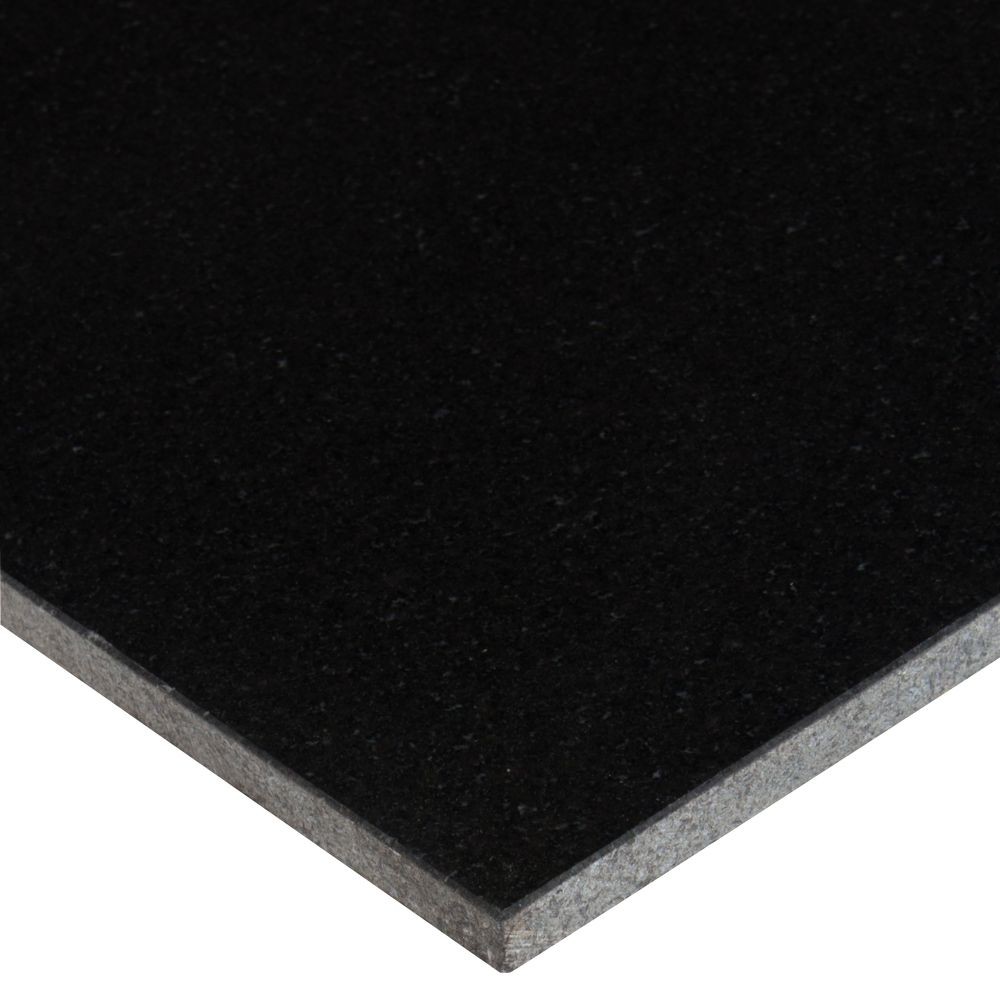

Premium Black 18X18 Polished Granite Tile – Floor Tiles USA

Related Posts:

- Commercial Porcelain Tile Flooring

- Ideas Covering Tile Floors

- Steam Mop For Hardwood And Tile Floors

- Shaw Vinyl Tile Flooring

- Herringbone Wood Look Tile Floor

- Chair Casters For Tile Floors

- Bona Mops For Tile Floors

- How Clean Porcelain Tile Floor

- How To Install Natural Stone Tile Flooring

- How Much To Install Tile Floor Per Square Foot

Introduction

Ceramic tile floor molding is an essential component of any tiling project. It helps to provide a finished look and can protect against water damage, dirt, and debris. Ceramic tile floor molding also helps to improve the overall aesthetic of the tiled area and can make it more attractive. In this article, we will discuss everything you need to know about ceramic tile floor molding, including what it is, how it works, types of molding, and FAQs.

What Is Ceramic Tile Floor Molding?

Ceramic tile floor molding is a type of product used to provide a finished look to any tiled floor surface. It is usually made from plastic or metal and can come in various shapes and sizes. The main purpose of ceramic tile floor molding is to protect the edges of the tiles from damage due to water, dirt, and debris. Additionally, ceramic tile floor molding can also be used to give the tiled area a more aesthetically pleasing and polished look.

How Does Ceramic Tile Floor Molding Work?

Ceramic tile floor molding is installed along the edges of the tiled area where it meets other surfaces such as walls or other floors. It acts as a barrier between the tiles and these other surfaces in order to prevent any water, dirt, or debris from entering the gaps between them. Additionally, ceramic tile floor molding also adds a decorative touch to the tiled area and can help to create a more polished look.

Types Of Ceramic Tile Floor Molding

There are several different types of ceramic tile floor molding available on the market today. The most common type is quarter round, which is typically made from either plastic or metal and comes in various sizes and shapes. Quarter round moldings are typically used along the edges of walls or other surfaces that meet up with the tiled area in order to protect against water damage. Additionally, there are also cove base moldings which are typically used along the bottom edges of walls or other surfaces that meet up with the tiled area in order to provide an aesthetically pleasing finished look. Other types include baseboard moldings which are typically used along the top edges of walls or other surfaces that meet up with the tiled area in order to provide an aesthetically pleasing finished look as well as corner blocks which are used at corners where two walls meet up with each other in order to provide an aesthetically pleasing finished look.

FAQs

Q: What is ceramic tile floor molding?

A: Ceramic tile floor molding is a type of product used to provide a finished look to any tiled floor surface. It is usually made from plastic or metal and can come in various shapes and sizes. The main purpose of ceramic tile floor molding is to protect the edges of the tiles from damage due to water, dirt, and debris. Additionally, ceramic tile floor molding can also be used to give the tiled area a more aesthetically pleasing and polished look.

Q: How does ceramic tile floor molding work?

A: Ceramic tile floor molding is installed along the edges of the tiled area where it meets other surfaces such as walls or other floors. It acts as a barrier between the tiles and these other surfaces In order to prevent any water, dirt, or debris from entering the gaps between them. Additionally, ceramic tile floor molding also adds a decorative touch to the tiled area and can help to create a more polished look.