Marble Floor Grinding Machine

Related Images about Marble Floor Grinding Machine

BK Counter Top – floor grinding machine

Test a little area to make sure it's diluted correctly first to check out for any reactions. All you require is a clean and non-treated dust mop in addition to some professional cleaning products created specifically for marble. For those that must stay away from irritants such as dust to keep the allergies of theirs at bay marble flooring is best. Your marble floors will be downright flat and there'll be no deep scratch or perhaps stain.

China Good Price Four Heads Hand Marble Granite Polishing Concrete Grinding Machine – China

It is a substance which is needed not only in homes but also places of work as well as public buildings. By and large, it is able to make the full marble cleaning treatment more effective as well. Marble flooring as well as granite flooring materials are widely popular and also have noticed a big growth of sales over the past 10 years or even so. The marble floors tile patterns with its gentle designs & colors appear to be gorgeous for office space or residential flooring.

3 Phase 16 Heads 11HP Stone Floor Polisher Terrazzo Polishing Machine Equipment

This can avert your floor from digesting some moisture and restore its fine look. Porous nature of marble causes it to be very vulnerable to acid attacks. You may possibly want to check out with a few builders and see if they've sample of home you can check out to see if it is the flooring pick for you personally. Although you are going to have to take care of it just like some other floor, marble won't scratch easily.

Pro850 Self Propelled Concrete Grinding Machine Floor Polishing Machine Concrete Grinder – Buy

Stone Floor Grinding Machine

useful floor grinding machine surface marble polished machine – XY-880 – Xingyi (China Trading

Marble Grinding Machine from China – StoneContact.com

150mm Heavy-duty bench grinder and wire wheel. 370 Watt. BG150XLW/98

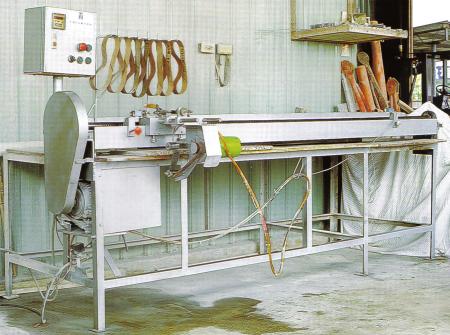

EDGE BELT POLISHING MACHINE semi-automated cutting, profiling and milling machine semi-automated

220v And 380v Granite Marble Stone Grinder Concrete Floor Polishing Machine – Buy Granite Marble

BK Hand Grinder – floor grinding machine

Marble Floor Aegean Stone Limited

Asl-t15 Ride-on Floor Grinding Machine & Diamond Polishing Machine Concrete Floor Grinder With

BK 850 – floor grinding machine

Related Posts:

- How To Restore Shine To Marble Floors

- Marble Floor Tiles Ireland

- Marble Floor Medallions Sale

- Marble Floor Repair Kit

- How To Wash Marble Floor

- Botticino Marble Floor Tiles

- Crazy Marble Flooring Designs

- How To Maintain Marble Flooring

- Marble Floor Tile Care Maintenance

- Hexagon Marble Floor

Marble Floor Grinding Machine: Achieving Flawless Floors

Introduction:

Marble has long been admired for its beauty and elegance. Its unique veining patterns and natural variations in color make it a popular choice for flooring in homes, offices, and commercial spaces. However, over time, marble floors can become dull, scratched, or stained due to heavy foot traffic, spills, and improper maintenance. To restore their original shine and luster, professional marble floor grinding machines are used. In this article, we will delve into the details of these machines and explore how they can transform worn-out marble floors into stunning works of art.

1. Understanding Marble Floor Grinding Machines:

Marble floor grinding machines are specially designed to polish, restore, and maintain the glossy appearance of marble surfaces. These machines feature powerful motors that rotate diamond-impregnated grinding discs or pads at high speeds. The grinding action efficiently removes scratches, stains, and unevenness from the surface of the marble floor, resulting in a smooth and polished finish.

2. The Process of Marble Floor Grinding:

a) Preparation: Before starting the actual grinding process, it is crucial to prepare the area properly. This involves removing any furniture or obstacles that may hinder the machine’s movement. Additionally, any loose debris or dirt should be swept away.

b) Coarse Grinding: The first step in the grinding process involves using coarse-grit diamond discs or pads to remove deep scratches and unevenness from the marble floor. The machine is moved in a back-and-forth motion across the entire surface to ensure even grinding.

c) Fine Grinding: Once the coarse grinding is complete, finer grit diamond discs or pads are employed to further smoothen the surface. This step gradually reduces the coarseness of the scratches left by the previous stage.

d) Polishing: After achieving a smooth surface through fine grinding, polishing compounds are applied to enhance the shine of the marble floor. The machine’s rotating discs or pads, combined with the polishing agents, create a mirror-like finish on the marble surface.

e) Sealing: To protect the newly polished marble floor from stains and spills, a sealant is applied. This creates a barrier that prevents liquids from penetrating the surface, making it easier to clean and maintain the floor.

3. Advantages of Using Marble Floor Grinding Machines:

a) Restoration of Appearance: Marble floors that have lost their shine and appear dull can be brought back to life through grinding. The process removes scratches, stains, and imperfections, revealing the natural beauty of the marble.

b) Increased Durability: By eliminating scratches and unevenness, grinding strengthens the surface of the marble floor. This enhances its ability to withstand heavy foot traffic and reduces the likelihood of further damage.

c) Cost-Effective: Rather than replacing damaged or worn-out marble floors, grinding offers a more economical solution. It allows for the restoration of existing floors at a fraction of the cost of installation.

d) Versatility: Marble floor grinding machines can be used on various types of marble surfaces, including floors, countertops, and walls. They are also effective in polishing other stone materials such as granite and terrazzo.

4. Frequently Asked Questions:

Q1: Can I grind my marble floors myself without professional help?

A1: While it is possible to rent marble floor grinding machines for DIY projects, it is highly recommended to seek professional assistance. Improper use of these machines can lead to irreversible damage to the marble surface. Professionals have the Experience and expertise to ensure a proper and safe grinding process.

Q2: How long does the grinding process take?

A2: The duration of the grinding process depends on various factors, including the size of the area, the severity of the damage, and the type of marble. It can range from a few hours to several days for larger projects.

Q3: How often should I grind my marble floors?

A3: The frequency of grinding depends on the level of wear and tear your marble floors experience. Generally, it is recommended to have them professionally ground every 1-3 years to maintain their appearance and durability.

Q4: Can grinding completely remove deep scratches from my marble floor?

A4: Grinding can significantly reduce the visibility of deep scratches, but it may not completely eliminate them. In some cases, additional steps such as honing or further polishing may be required to achieve the desired results.

Q5: Do I need to seal my marble floors after grinding?

A5: Yes, sealing is an important step after grinding to protect the newly polished surface from stains and spills. It helps maintain the appearance of the floor and makes it easier to clean and maintain.

Q6: Can I walk on my marble floors immediately after grinding?

A6: It is recommended to wait for at least 24 hours before walking on freshly ground marble floors. This allows sufficient time for any sealants or polishing agents to fully cure and harden.